Multifunctional compound drug eluting slow-release system and preparation method thereof

A technology of drug coating and composite coating, which is applied in the field of orthopedic titanium, medical equipment, and magnesium alloy internal implants. It can solve the problems of low bonding strength of the coating, drug burst release, singleness, etc., and achieve good antibacterial effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Titanium alloy orthopedic implants with porous TiO surface 2 For the transition layer, the degradable polymer is PLA, and the drug is gentamicin.

[0030] Preparation steps:

[0031] 1. Preparation of porous ceramic transition layer:

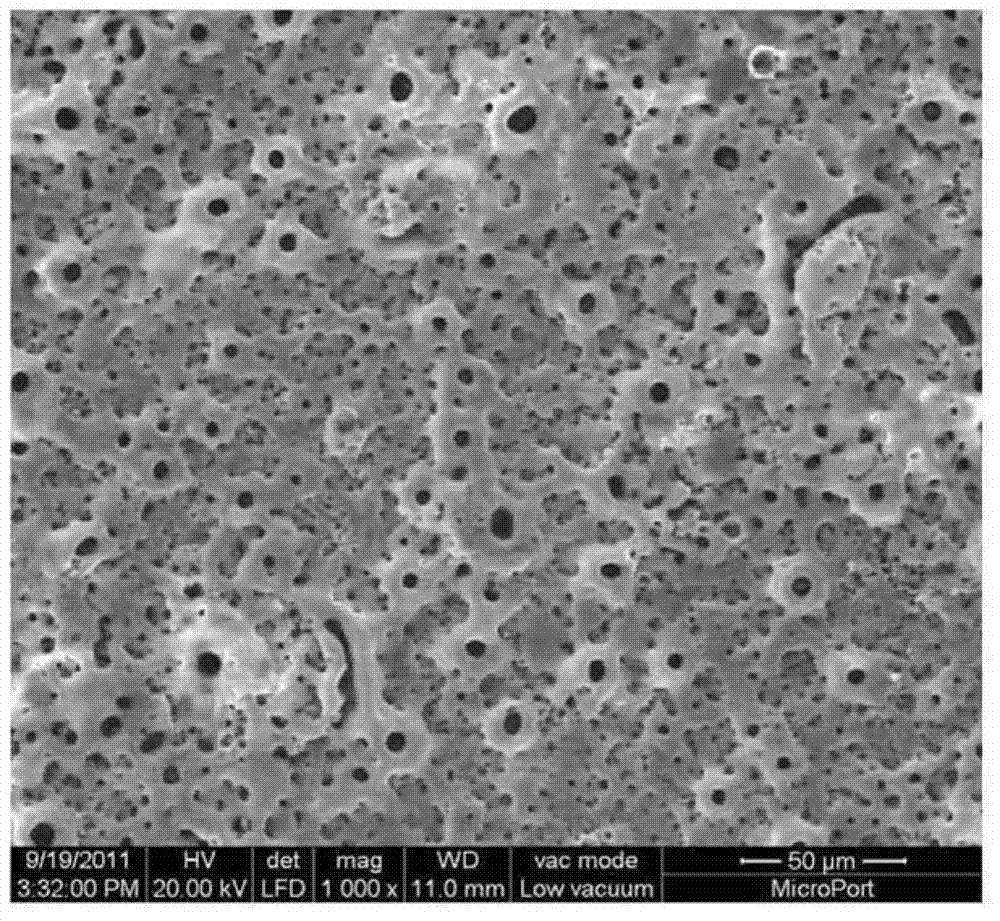

[0032] Using plasma oxidation technology, a porous ceramic transition layer is prepared on the surface of the titanium or magnesium alloy substrate, and the bottom layer is dense TiO 2 layer, the upper layer is porous TiO 2 layer, the pore size is 100nm-3μm, the coating thickness is 10-50μm, the preparation voltage is 100-500V, the voltage changes step by step, the current is 1-3A, the time is 1-20min, and the oxidizing solution is silicate, phosphate, etc.

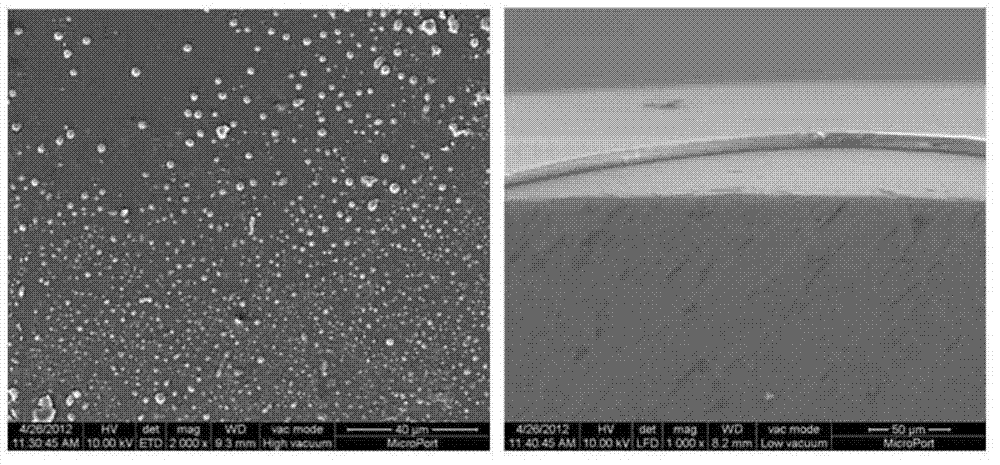

[0033] 2. Preparation of drug solution: First, accurately weigh despun polylactic acid (DL-PLA) (PDL04), dissolve it in tetrahydrofuran (THF), add the prepared aqueous solution of gentamicin to the polymer solution to form DL-PLA , a mixed solution of gentamicin. Spray or dip th...

Embodiment 2

[0036] Preparation of Porous TiO on the Surface of Titanium Alloy Orthopedic Implants 2 The transition layer, the degradable coating is a mixture of PLGA and collagen, and the drug is a mixture of gentamicin and vancomycin.

[0037] Preparation:

[0038] 1. Preparation of porous ceramic transition layer:

[0039] Using plasma oxidation technology, a porous ceramic transition layer is prepared on the surface of the metal substrate, and the bottom layer is dense TiO 2 layer, the upper layer is porous TiO 2 layer, the thickness of the coating is 10-50 microns, the preparation voltage is 100-500V, the voltage changes step by step, the current is 1-3A, the time is 1-20min, and the oxidizing solution is silicate, phosphate, etc.

[0040] 2. Preparation and preparation of drug solution: firstly, accurately weigh PLGA, dissolve it in tetrahydrofuran (THF), add the prepared mixed aqueous solution of gentamicin and vancomycin to the polymer solution, and form a mixed solution. Spray...

Embodiment 3

[0043] Preparation of Porous Mg(OH) on the Surface of Magnesium Alloy Orthopedic Implants 2 and MgO transition layer, DL-PLA is selected as the degradable polymer, and the drug is gentamicin.

[0044] Preparation:

[0045] 1. Preparation of porous ceramic transition layer:

[0046] Using plasma oxidation technology, a porous ceramic transition layer is prepared on the surface of the metal substrate, the bottom layer is a dense MgO layer, and the upper layer is porous MgO / Mg(OH) 2 layer, the thickness of the coating is 5-30 microns, the preparation voltage is 20-200V, the voltage changes step by step, the current is 0.1-2A, the time is 1-20min, and the oxidizing solution is silicate, phosphate, etc.

[0047] 2. Preparation and preparation of the drug solution: First, accurately weigh DL-PLA, dissolve it in tetrahydrofuran (THF), add the prepared gentamicin aqueous solution into the polymer solution, and form DL-PLA and gentamicin. mixture. Spray or dip the prepared drug sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com