Metal oxide thin film transistor array substrate, manufacturing method thereof, and display device

A transistor array and oxide thin film technology, which is applied in the manufacture of semiconductor/solid state devices, electric solid state devices, semiconductor devices, etc., can solve the problems of increasing the complexity of the fabrication process of the array substrate structure and reducing the productivity of the metal oxide thin film transistor array substrate. , to achieve the effect of improving the etching selection ratio, simplifying the structure and manufacturing process, and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

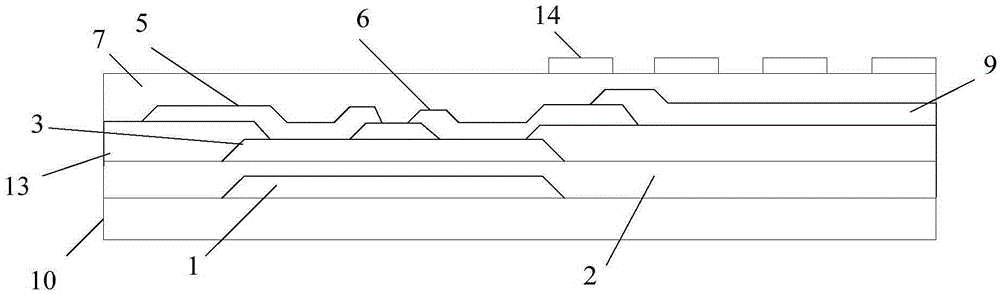

[0061] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

[0062] Embodiments of the present invention provide a metal oxide thin film transistor array substrate, a manufacturing method thereof, and a display device, which can simplify the structure and manufacturing process of the metal oxide thin film transistor array substrate, and improve the productivity of the metal oxide thin film transistor array substrate.

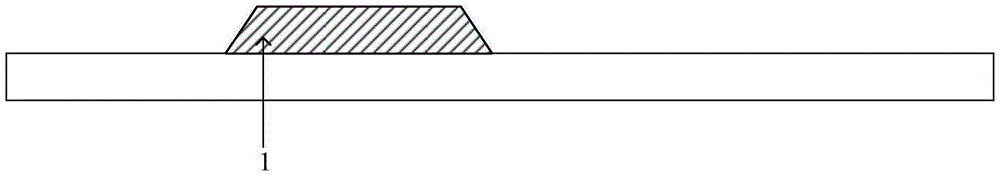

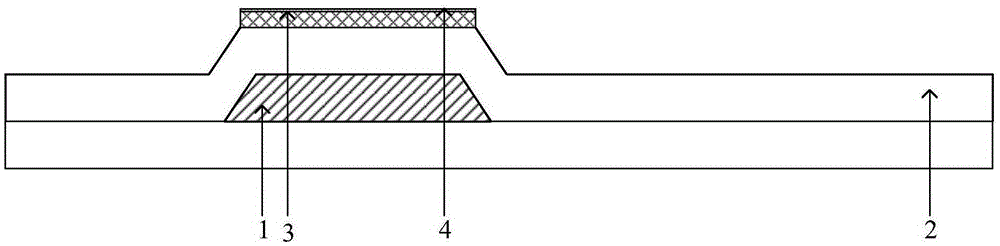

[0063] The present invention provides a method for manufacturing a metal oxide thin film transistor array substrate. The method includes: forming an active layer composed of crystalline metal oxide.

[0064] In the array substrate made by the present invention, the active layer is composed of crystalline metal oxide, and the acid etching rate of the metal oxide after the amorphous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com