Method for preparing silicon oxide-based ceramic core for titanium and titanium alloy casting

A silicon oxide-based, ceramic core technology, which is applied in the field of titanium alloy precision casting processing, can solve the problems of difficult core removal, hydration, etc., achieve low cost and improve chemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

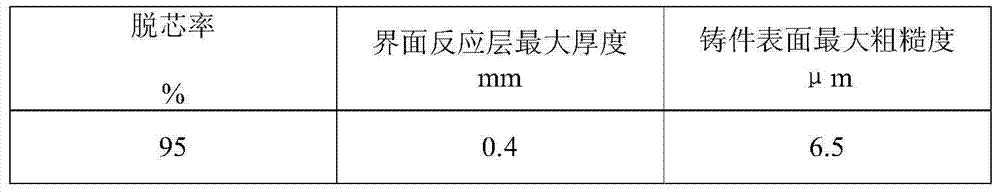

Embodiment 1

[0019] The method for preparing a silicon oxide-based ceramic core for casting titanium and titanium alloys is characterized in that the steps of the method are:

[0020] Step 1. Preparation of silicon oxide core blank

[0021] 85kgSiO 2 , 7.5kg of paraffin wax, 6kg of beeswax and 1.5kg of oleic acid are mixed, then shaped and sintered. During the sintering process, the paraffin, beeswax and oleic acid are all volatilized, leaving only pure silica, so the pure silica core is obtained after sintering Blank;

[0022] Step 2, preparing ZrO on the surface of the silicon oxide core blank 2 or Y 2 o 3 The nano film, the preparation process is as follows:

[0023] ⑴Preparation of ZrO by sieving method 2 or Y 2 o 3 Powder, the particle size is controlled at 200-400 mesh, in ZrO 2 or Y 2 o 3 After adding adhesive to the powder and mixing, stir evenly to prepare a coating with a flow cup viscosity of 40S. The adhesive is silica sol, zirconium acetate or yttrium sol, and the a...

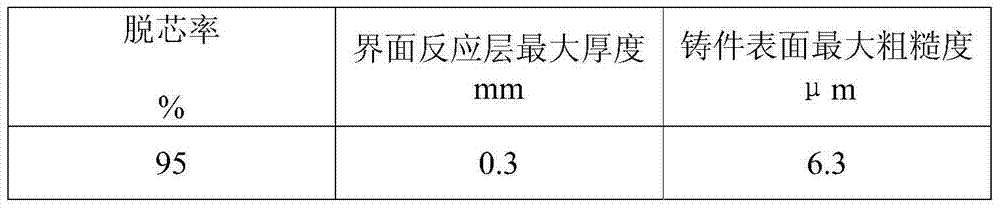

Embodiment 2

[0032] The method for preparing a silicon oxide-based ceramic core for casting titanium and titanium alloys is characterized in that the steps of the method are:

[0033] Step 1. Preparation of silicon oxide core blank

[0034] Mix 95kg CaO, 4kg paraffin, 0.5kg beeswax, and 0.5kg oleic acid, then shape and sinter. During the sintering process, the paraffin, beeswax and oleic acid are all volatilized, leaving only pure silicon oxide, so pure silicon oxide is obtained after sintering core blank;

[0035] Step 2, preparing ZrO on the surface of the silicon oxide core blank 2 or Y 2 o 3 The nano film, the preparation process is as follows:

[0036] ⑴Preparation of ZrO by sieving method 2 or Y 2 o 3 Powder, the particle size is controlled at 200-400 mesh, in ZrO 2 or Y 2 o 3 After adding adhesive to the powder and mixing, stir evenly to prepare a coating with a flow cup viscosity of 30S. The adhesive is silica sol, zirconium acetate or yttrium sol, and the amount of adhes...

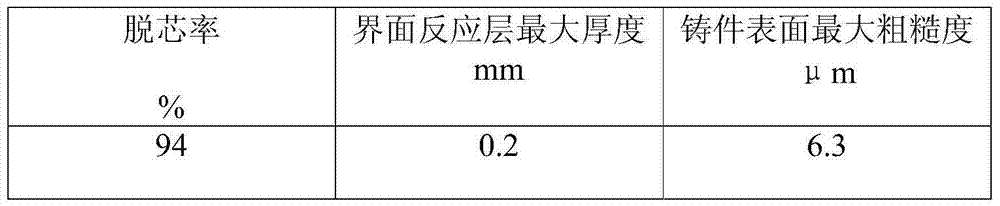

Embodiment 3

[0045] The method for preparing a silicon oxide-based ceramic core for casting titanium and titanium alloys is characterized in that the steps of the method are:

[0046] Step 1. Preparation of silicon oxide core blank

[0047] Mix 90kg of CaO, 6kg of paraffin, 3.5kg of beeswax, and 0.5kg of oleic acid, then shape and sinter. During the sintering process, paraffin, beeswax and oleic acid are all volatilized, leaving only pure silicon oxide, so pure silicon oxide is obtained after sintering core blank;

[0048] Step 2, preparing ZrO on the surface of the silicon oxide core blank 2 or Y 2 o 3 The nano film, the preparation process is as follows:

[0049] ⑴Preparation of ZrO by sieving method 2 or Y 2 o 3 Powder, the particle size is controlled at 200-400 mesh, in ZrO 2 or Y 2 o 3 After adding adhesive to the powder and mixing, stir evenly to prepare a coating with a flow cup viscosity of 5S. The adhesive is silica sol, zirconium acetate or yttrium sol, and the amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com