Autoclaved aerated concrete plate produced by using Yellow River sand, and production method thereof

An autoclaved aerated, concrete slab technology, applied in the field of building wall materials, can solve the problems of no major advantages, low product added value, affecting the enthusiasm for sand control with sand, etc., and achieves high rigidity, low cost, and improved construction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

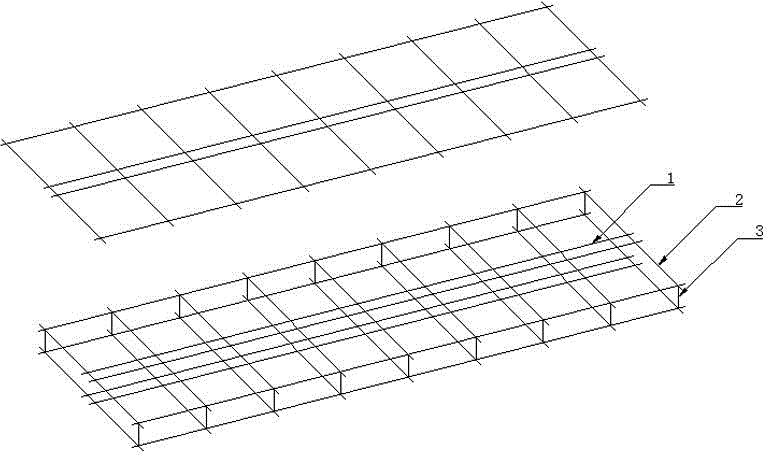

[0031] An autoclaved aerated concrete slab prepared from Yellow River sand, the weight ratio of the base material components of the concrete slab body is: 2450 kg of Yellow River sand, 480 kg of cement, 420 kg of quicklime, 100 kg of slaked lime, 47kg of desulfurized gypsum, 50 kg of magnesite, 4.5 kg of aluminum powder paste, and 0.08 kg of acacia powder. SiO in the Yellow River sand 2 The content is between 60~75%, the organic matter is not higher than 2.5%, and the mud content is not higher than 2.0%. The cement is P.O 42.5 cement; the aluminum powder paste is a water-based aluminum powder paste. The concrete slab also includes a reinforcement mesh, and the reinforcement mesh is composed of upper and lower layers of reinforcement mesh sheets and steel bars connecting the upper and lower layers of mesh sheets; the specifications of the reinforcement bars are HPB235, φ5~φ6 mm.

[0032] The above-mentioned preparation method of the autoclaved aerated concrete slab prepared b...

Embodiment 2

[0041] An autoclaved aerated concrete slab prepared from Yellow River sand, the weight ratio of the base material components of the concrete slab body is: 3300 kg of Yellow River sand, 500 kg of cement, 600 kg of quicklime, 120 kg of slaked lime, 50 kg of desulfurized gypsum, 50 kg of magnesite, 4.0 kg of aluminum powder paste, and 0.10 kg of tea saponin. SiO in the Yellow River sand 2 The content is between 60~75%, the organic matter is not higher than 2.5%, and the mud content is not higher than 2.0%. The cement is P.O 42.5 cement; the aluminum powder paste is a water-based aluminum powder paste. The concrete slab also includes a reinforcement mesh, and the reinforcement mesh is composed of upper and lower layers of reinforcement mesh sheets and steel bars connecting the upper and lower layers of mesh sheets; the specifications of the reinforcement bars are HPB235, φ5~φ6 mm.

[0042] The above-mentioned preparation method of the autoclaved aerated concrete slab prepared by...

Embodiment 3

[0051] An autoclaved aerated concrete slab prepared from Yellow River sand, the weight ratio of the base material components of the concrete slab body is: 3500 kg of Yellow River sand, 700 kg of cement, 620 kg of quicklime, 30 kg of slaked lime, 42 kg of desulfurized gypsum, 37 kg of magnesite, 4.0 kg of aluminum powder paste, and 0.05 kg of pull-off powder. SiO in the Yellow River sand 2 The content is between 60~75%, the organic matter is not higher than 2.5%, and the mud content is not higher than 2.0%. The cement is P.O 42.5 cement; the aluminum powder paste is a water-based aluminum powder paste. The concrete slab also includes a reinforcement mesh, and the reinforcement mesh is composed of upper and lower layers of reinforcement mesh sheets and steel bars connecting the upper and lower layers of mesh sheets; the specifications of the reinforcement bars are HPB235, φ5~φ6 mm.

[0052] For the preparation method of the above-mentioned autoclaved aerated concrete slab prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com