A kind of spinning forming device of powder drug type cap

A technology of spin forming and liner, which is applied in the field of powder liner spinning device, which can solve the problem that it is difficult to meet the requirement of uniform circumferential density of high-quality liner, which affects product accuracy and mold life, and die Difficult to achieve rapid replacement and other problems, achieve high positioning accuracy and rotation stability, improve powder fluidity, and improve the effect of powder circumferential distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

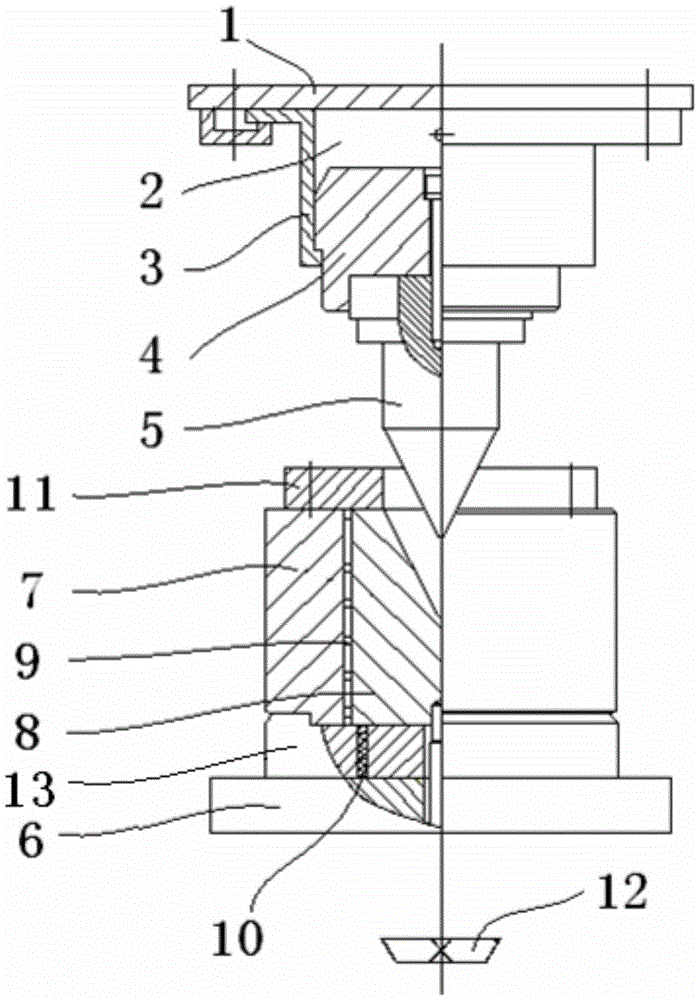

Method used

Image

Examples

Embodiment 1

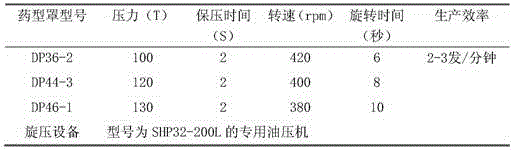

[0043] According to the technical solution of the present invention, the upper mold in this embodiment adopts an adjustable air cushion structure, the height of the air cavity is 30-40mm, and the air pressure range is 0.2-0.4MPa. The parameters in Table 1 are used to press the DP36-2 type medicine cover.

[0044] The drug-mask material component of this embodiment is: conventional copper-tungsten-based drug-mask formula, wherein the tungsten content is less than 15%.

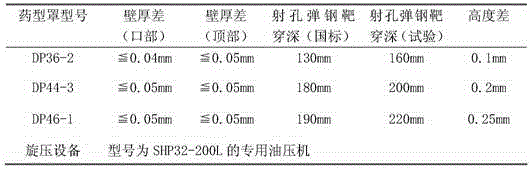

[0045] Relevant tests were carried out according to GB / T20488-2006 "Methods for Testing the Performance of Energy Concentrating Perforating Equipment for Oil and Gas Wells". Its penetration performance index is 20% higher than the national standard (GB / T20489-2006 "General Technical Specifications for Energy Concentrating Perforating Equipment for Oil and Gas Wells"), and its production efficiency and geometric dimension accuracy are high. See Table 2 for details.

Embodiment 2

[0047]This embodiment differs from Embodiment 1 in that a ball sleeve is used between the die and the fixed sleeve, and an elastic support device is used at the bottom. The ball sleeve adopts the specification of Φ80×5×75, the ball of the elastic device is Φ8, and the spring specification is Φ80×1.5×20.

[0048] The drug-mask material component of this embodiment is: a conventional copper-tungsten-based drug-mask formula, wherein the tungsten content is less than 15%.

[0049] Using the process parameters in Table 1 to press DP44-3 and DP46-1 drug-type covers, the geometric dimension accuracy is high, and the penetration performance index is 10%-15% higher than the national standard. See Table 2 for details.

[0050] Table 1

[0051]

[0052] Table 2

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com