Energy-saving distiller

A distillation device, energy-saving technology, applied in the direction of distillation separation, chemical instruments and methods, separation methods, etc., can solve the problems of high heating temperature in the heating zone, high energy consumption of distillation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the following embodiments, the process of distilling water is used for description. But it should be understood that in some special occasions, it can also be liquids of other properties, such as alcohol, gasoline, etc., and the present invention is not limited to the production of distilled water.

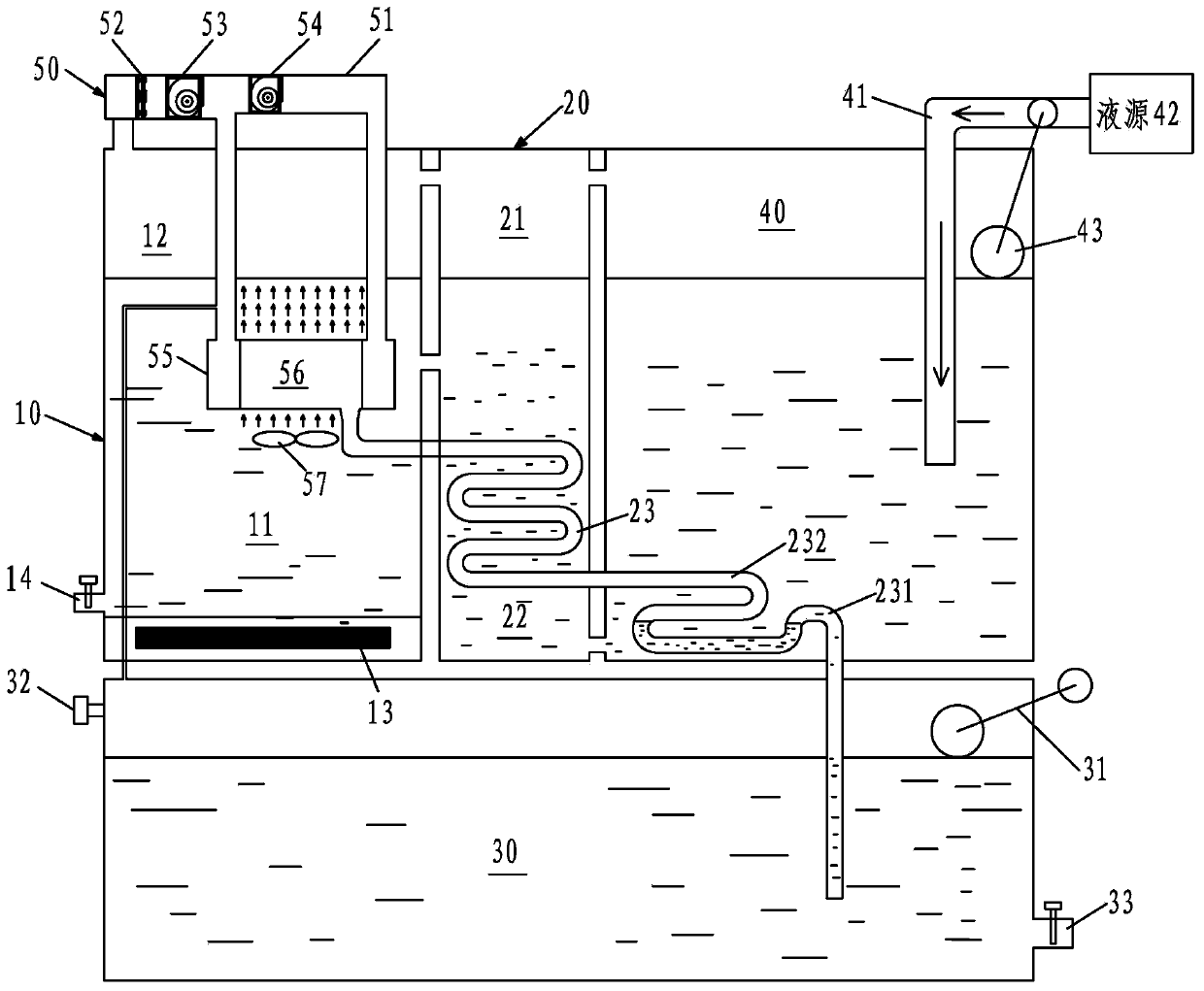

[0023] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the energy-saving distillation device of the present invention. exist figure 1 In the illustrated embodiment, the energy-saving distillation device includes a heating zone 10 , a heat cycle exchange zone 20 , a distilled water zone 30 and a water storage zone 40 . Wherein, the heating zone 10 is used to heat the water injected into the container to maintain a boiling state, so that the water can be continuously converted into water vapor; after the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com