Connection structure of superconducting wire, method of connecting superconducting wire, and superconducting wire for connection

A connection method and technology of superconducting wires, applied in superconducting/high-conducting conductors, usage of superconducting elements, superconducting magnets/coils, etc., can solve problems such as deterioration of superconducting layers, increase of current density, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred modes for carrying out the present invention will be described with reference to the drawings. However, in the embodiments described below, various limitations technically preferable for implementing the present invention are added, but the scope of the present invention is not limited to the following embodiments and illustrated examples.

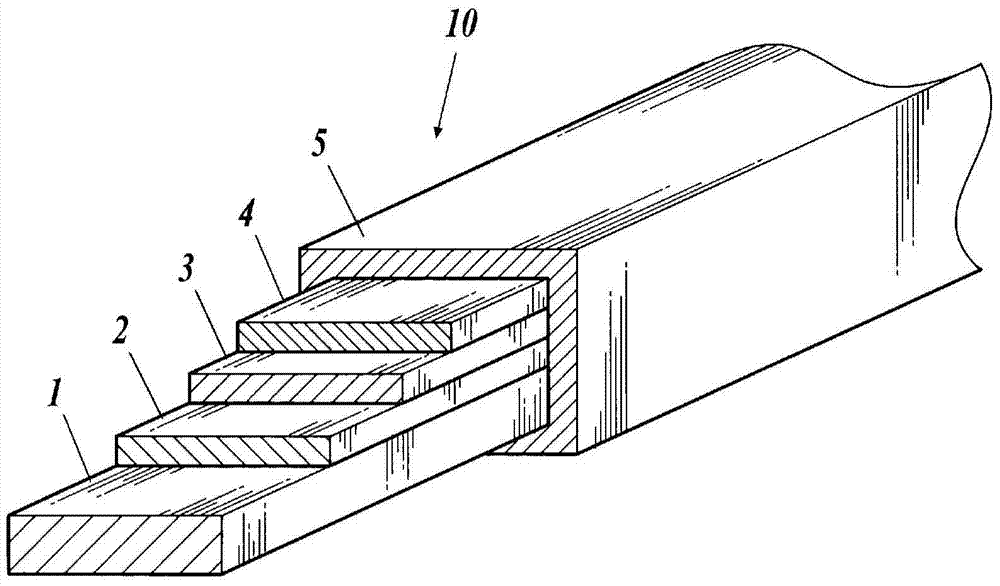

[0049] figure 1 It is an explanatory diagram showing a layer structure of a superconducting wire.

[0050] For example, if figure 1 As shown, the superconducting wire 10 is a tape-shaped superconducting wire, which has: a laminate formed by sequentially laminating an intermediate layer 2, a superconducting layer 3, and a protective layer 4 on a substrate 1; and a stabilization layer covering the periphery of the laminate. 5.

[0051] The substrate 1 is, for example, a strip-shaped metal substrate made of low-magnetic non-oriented metal such as Hastelloy (HASTELLOY, registered trademark).

[0052] The int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com