High-voltage drive dedicated power supply for piezoelectric smart valve positioners

A technology of intelligent valve and high-voltage drive, which is applied in the direction of instruments, electrical components, and adjustment of electric variables. It can solve the problems of high conversion efficiency, small size, and high voltage conversion ratio, and achieve small size, fewer peripheral devices, and stable output current and voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

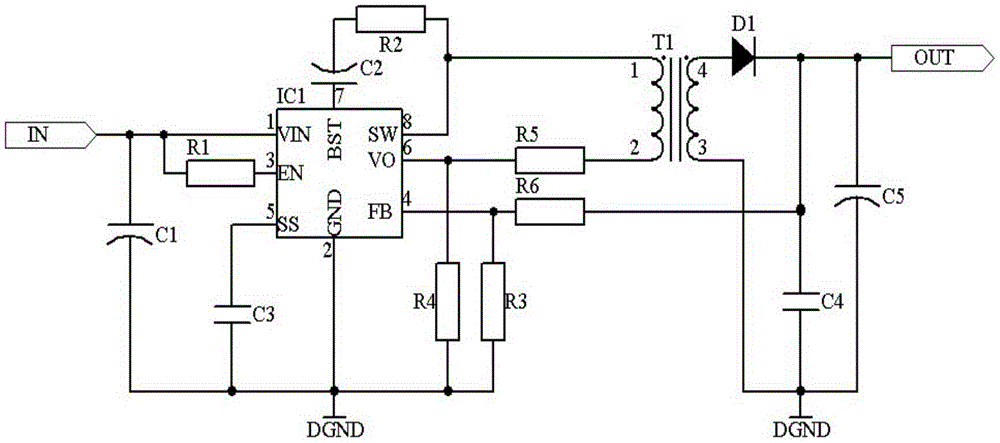

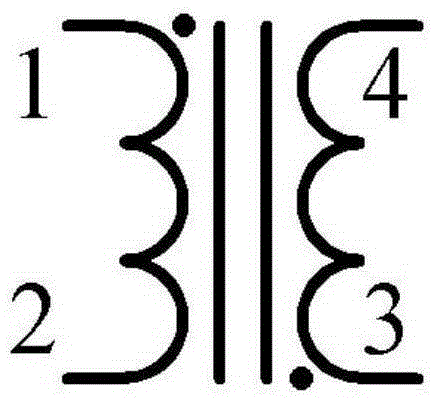

[0016] Such as figure 1 As shown, a high-voltage drive dedicated power supply for a piezoelectric intelligent valve positioner includes an input filter circuit, an IC1 step-down circuit, an overvoltage protection circuit, an output voltage adjustment circuit, a high-frequency boost circuit, and a rectification filter circuit. The circuit is composed of electrolytic capacitor C1, the positive pole of electrolytic capacitor C1 is connected to the input DC power supply, and the negative pole is connected to the ground DGND;

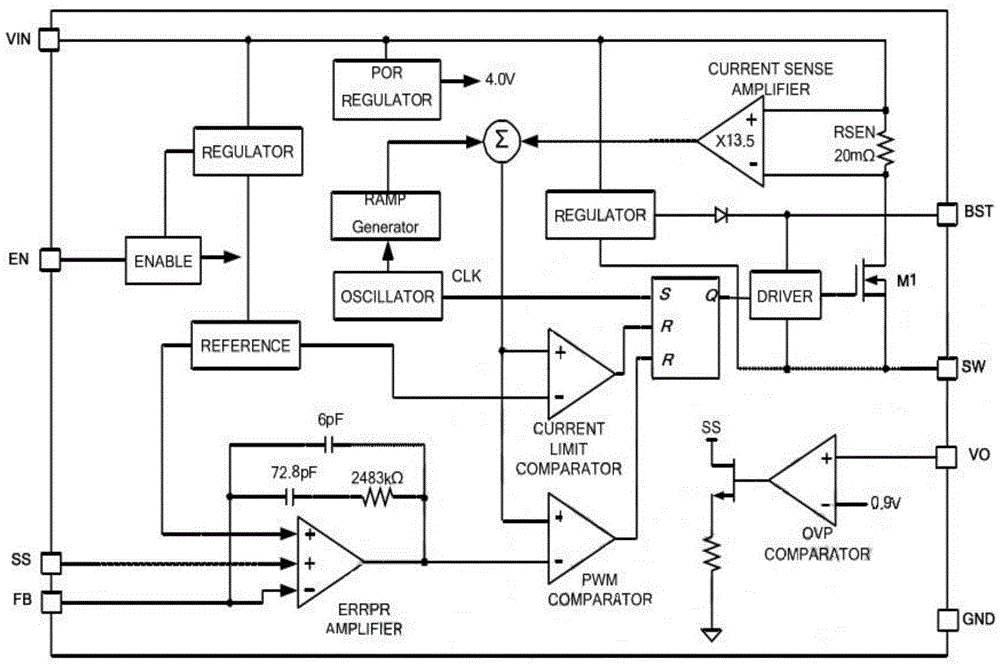

[0017] IC1 step-down circuit is composed of soft-start capacitor C3, bootstrap capacitor C2, chip enable resistor R1, bootstrap resistor R2 and IC1 integrated device, wherein the positive pole of bootstrap capacitor C2 is connected to pin 7 of IC1 integrated device, The negative pole of capacitor C2 is connected to one end of bootstrap resistor R2, and the other end of bootstrap resistor R2 is connected to pin 8 of IC1 integrated device; one end of chip enab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com