Gel polymer energy storage lithium ion battery and preparation method thereof

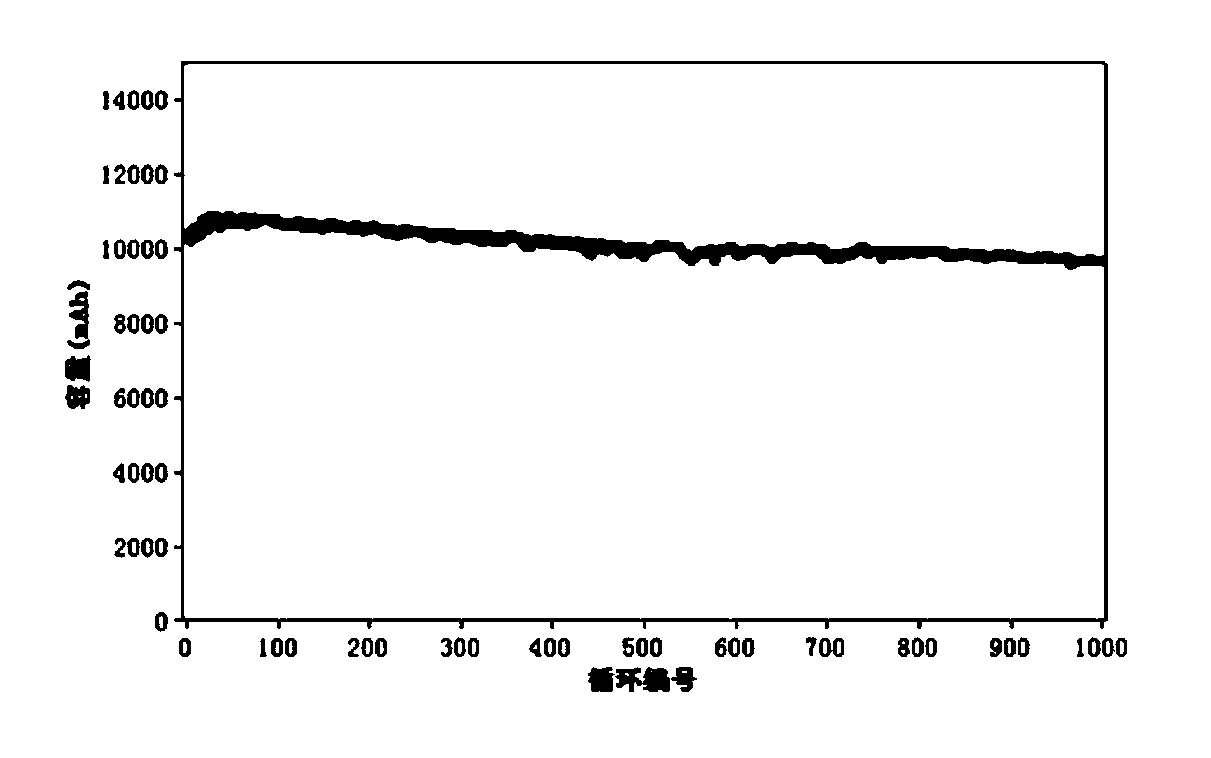

A gel polymer, lithium-ion battery technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of reducing the quality of active materials, poor cycle performance, and no capacity, to improve specific energy, The effect of long cycle life and capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Positive electrode preparation: 95% of the surface is coated with LiFePO 4 LiNi 0.5 mn 1.5 o 4, 3% KS-6, and 2% PVDF were mixed in N-methylpyrrolidone (NMP) to form a slurry, uniformly coated on a 16 μm aluminum foil current collector, dried, compacted, and cut to obtain a positive electrode.

[0027] Negative electrode preparation: 93% Li 4 Ti 5 o 12 , 4% SFG-6, and 3% PVDF were mixed in N-methylpyrrolidone (NMP) to form a slurry, uniformly coated on a 10 μm copper foil current collector, dried, compacted, and cut to obtain the negative electrode.

[0028] Preparation of gel polymer separator: Dissolve polyvinylidene fluoride and hexafluoropropylene (PVDF-HFP) copolymer in acetone, add 20% nano-scale Al 2 o 3 Powder, mixed into a slurry, evenly coated on a 12 μm thick PE base film, with a thickness of 4 μm on one side, and dried to obtain a gel polymer separator.

[0029] Electrolyte preparation: Mix ethylene carbonate (EC), diethyl carbonate (DEC), and ethyl m...

Embodiment 2

[0032] Positive electrode preparation: 95% of the surface is coated with LiFePO 4 LiNi 0.5 mn 1.5 o 4 , 3% carbon nanotubes (CNTs), and 2% PVDF were mixed in N-methylpyrrolidone (NMP) to form a slurry, uniformly coated on a 16 μm aluminum foil current collector, dried, compacted, and cut to obtain positive electrode.

[0033] Negative electrode preparation: 93% Li 4 Ti 5 o 12 , 4% carbon nanotubes (CNTs), 3% PVDF mixed in N-methylpyrrolidone (NMP) to form a slurry, evenly coated on a 10μm copper foil current collector, dried, compacted, cut, get the negative pole.

[0034] Other steps are the same as in Example 1.

Embodiment 3

[0036] Positive electrode preparation: 95% of the surface is coated with LiFePO 4 LiNi 0.5 mn 1.5 o 4 , 3% KS-6, and 2% PVDF were mixed in N-methylpyrrolidone (NMP) to form a slurry, uniformly coated on a 16 μm aluminum foil current collector, dried, compacted, and cut to obtain a positive electrode.

[0037] Negative electrode preparation: 93% Li 4 Ti 5 o 12 , 4% SFG-6, 1% CMC, and 2% SBR were mixed in deionized water to form a slurry, uniformly coated on a 10 μm copper foil current collector, dried, compacted, and cut to obtain a negative electrode.

[0038] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com