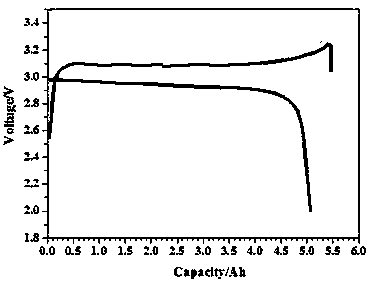

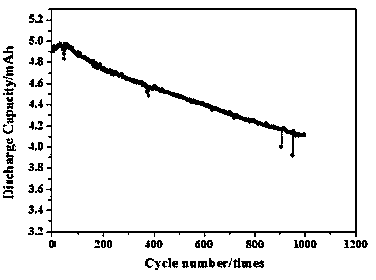

LiNi0.5Mn1.5O4/lithium titanate battery and preparation method thereof

A lithium titanate battery, lithium nickel manganese oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy formation of lithium dendrites, battery short circuit, low carbon material platform, etc., to improve comprehensive performance, The effect of improving energy density and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below with regard to specific embodiment, the present invention will be further described:

[0031] A lithium nickel manganese oxide / lithium titanate battery, comprising a positive electrode sheet, a negative electrode sheet, and an electrolyte, the positive electrode sheet comprising a positive electrode aluminum foil current collector and a positive electrode slurry coating coated on its surface, the negative electrode sheet comprising a negative electrode The aluminum foil current collector and the negative electrode slurry coating coated on the surface are characterized in that,

[0032] Positive and negative slurry coatings include the following materials:

[0033] The mass ratio of positive electrode slurry is based on lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ): conductive carbon Super-p: conductive carbon KS-15: binder PVDF (polyvinylidene fluoride) = 95:1:1:3, solvent is NMP (N-methylpyrrolidone), positive solid content 60%~ 65%;

[0034] The mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com