Piezoelectric electret film and preparation method thereof

A piezoelectric electret, thin film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. Solve the problem of high production cost, and achieve the effect of simplified operation, wide application prospect and improved piezoelectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

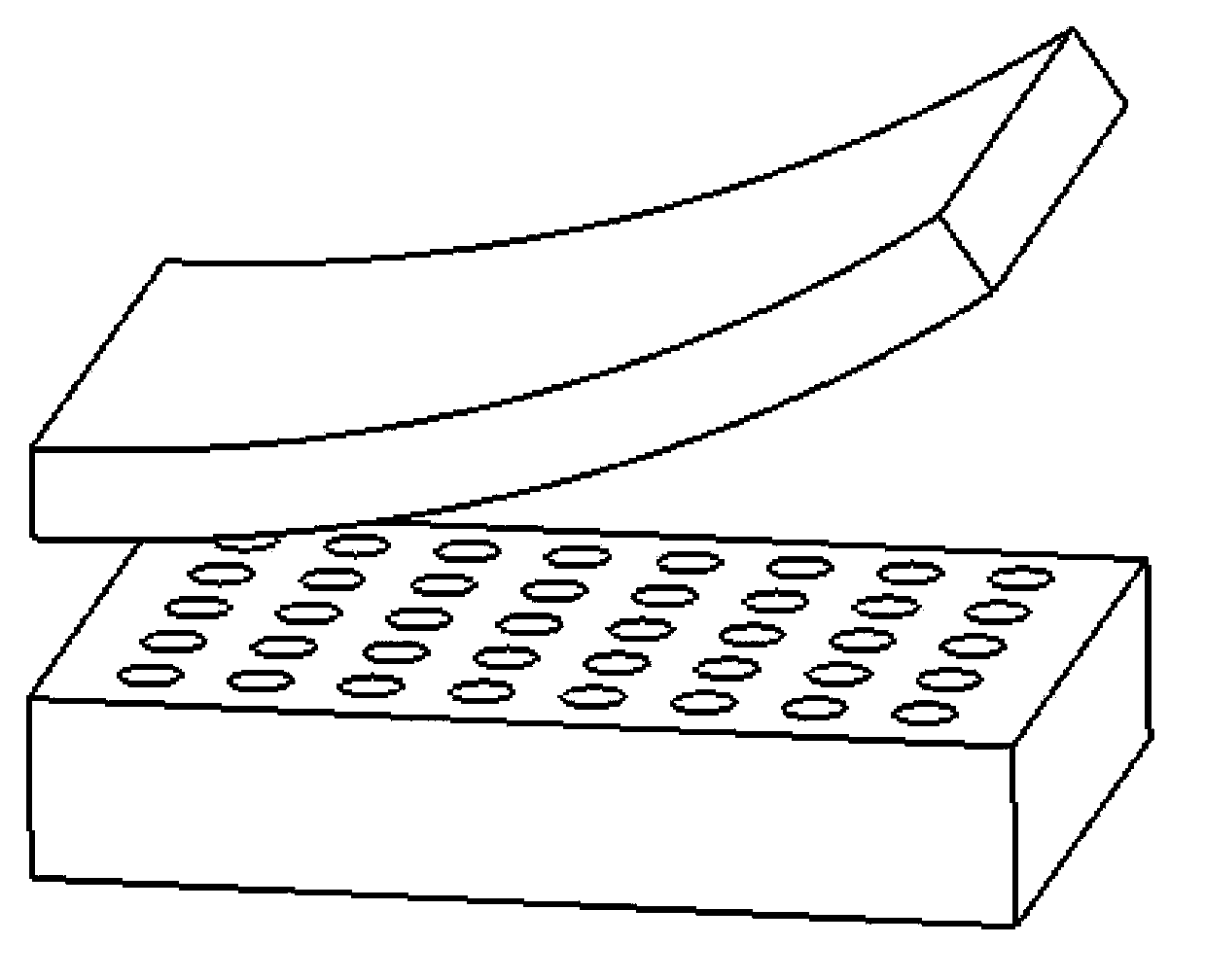

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a piezoelectric electret film, comprising steps: (1) coating a polymer solution on a template with nanowires, and then drying; after drying, removing the template to obtain a template with nanowires a porous first polymer film; (2) combining at least one first polymer film dried in step (1) with a second polymer film to form a cavity; and (3) polarizing to cause step (2) to form Opposite charges are distributed on the upper and lower surfaces of the cavity to form a piezoelectric electret film.

[0037] Attached below Figure 1-5 The preparation method of the piezoelectric electret thin film of the present invention will be described in detail.

[0038] Wherein, the step (1) is a process of forming the polymer membrane into a nanopore polymer membrane according to the requirement. In this step, the thickness of the coated polymer is greater than the height of the nanowires on the template, so as to ensure that the depth of...

Embodiment 1

[0051] 1) Preparation of polymer film solution: Put 1g of PVDF into a 100mL beaker, measure 8ml of dimethylacetamide (DMF) with a 10mL graduated cylinder, add it to the beaker to dissolve PVDF (11.7wt%), and then use the beaker with Seal it with plastic wrap, ultrasonic for 30 minutes, PVDF is completely dissolved, and set aside.

[0052] 2) Preparation of zinc oxide nanowire template: using equimolar hexamethylenetetramine (HMTA) and zinc nitrate hexahydrate (ZnNO 3 6(H 2 O)) composition of the culture solution, put the prepared substrate silicon wafer with the zinc oxide seed layer facing down, put it on the top of the culture solution, grow it in a water bath environment for 5 hours, the length of the nanowire is 3 microns, and the zinc oxide is completed After the nanowire array grows, it is heated and annealed (at a temperature of 145-155°C), cleaned with ultrasonic waves, blown dry with a nitrogen gun, and dried in a vacuum oven at 80°C for 1.5 hours, finally forming a ...

Embodiment 2

[0057] 1) Preparation of polymer film solution: Put 2g of PVDF into a 150mL beaker, measure 15ml of dimethylacetamide (DMF) with a 20mL graduated cylinder, add it to the beaker to dissolve PVDF (11.7wt%), and put the beaker with fresh-keeping Membrane sealed, ultrasonic 30min, PVDF completely dissolved, set aside.

[0058] 2) Preparation of zinc oxide nanowire template: using equimolar hexamethylenetetramine (HMTA) and zinc nitrate hexahydrate (ZnNO 3 6(H 2 O)) composed of the culture solution, put the silicon wafers of the two substrates with the zinc oxide seed layer facing down, put them on the top of the culture solution, grow in the water bath environment for 5 hours, the length of the nanowire is 3 microns, and the oxidation is completed After the zinc nanowire array grows, it is heated and annealed (at a temperature of 145-155°C). Preferably, after ultrasonic cleaning, it is blown dry with a nitrogen gun, and placed in a vacuum oven at 80°C for 1.5 hours to form an oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com