Novel lead-acid battery temperature liquid level sensor

A technology of lead-acid batteries and liquid level sensors, which is applied in the field of detection technology and sensors, can solve the problems of unguaranteed stability and reliability, non-corrosion resistance, non-oil resistance, etc., to ensure stability, prevent corrosion, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

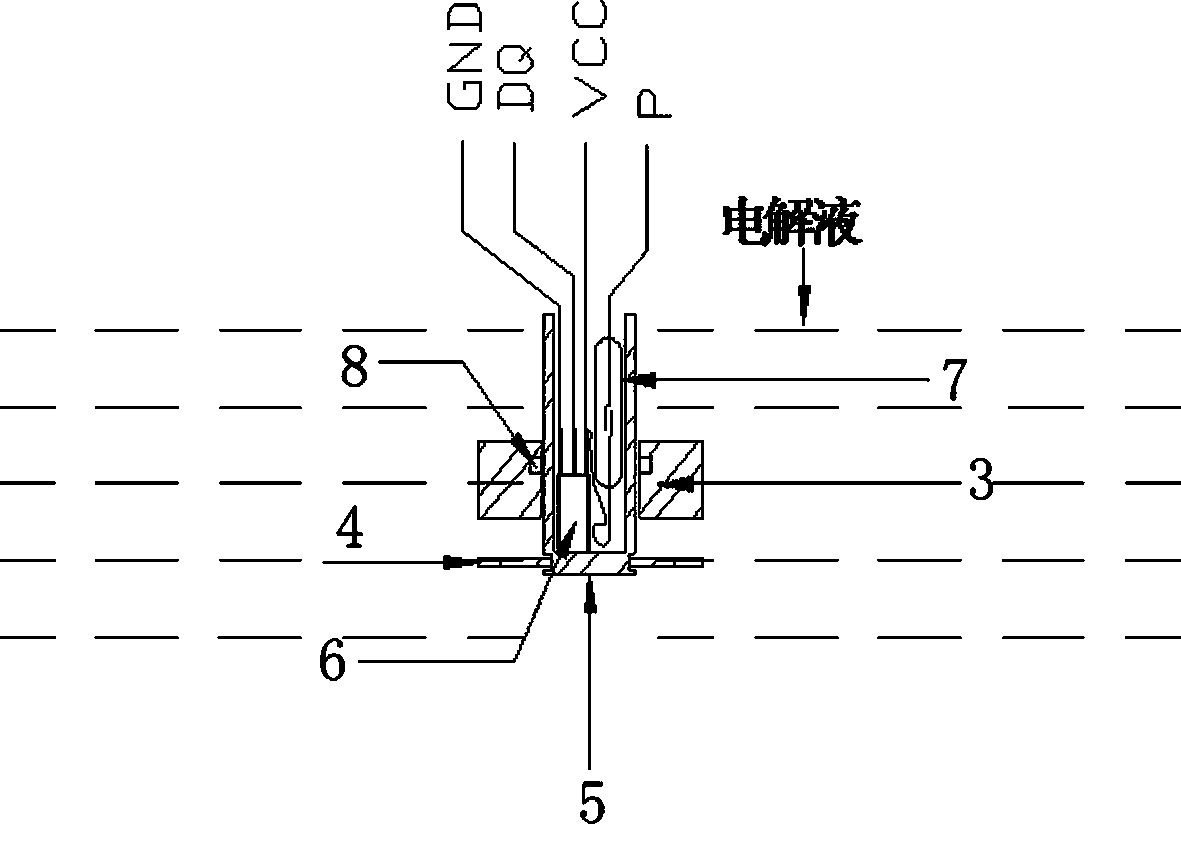

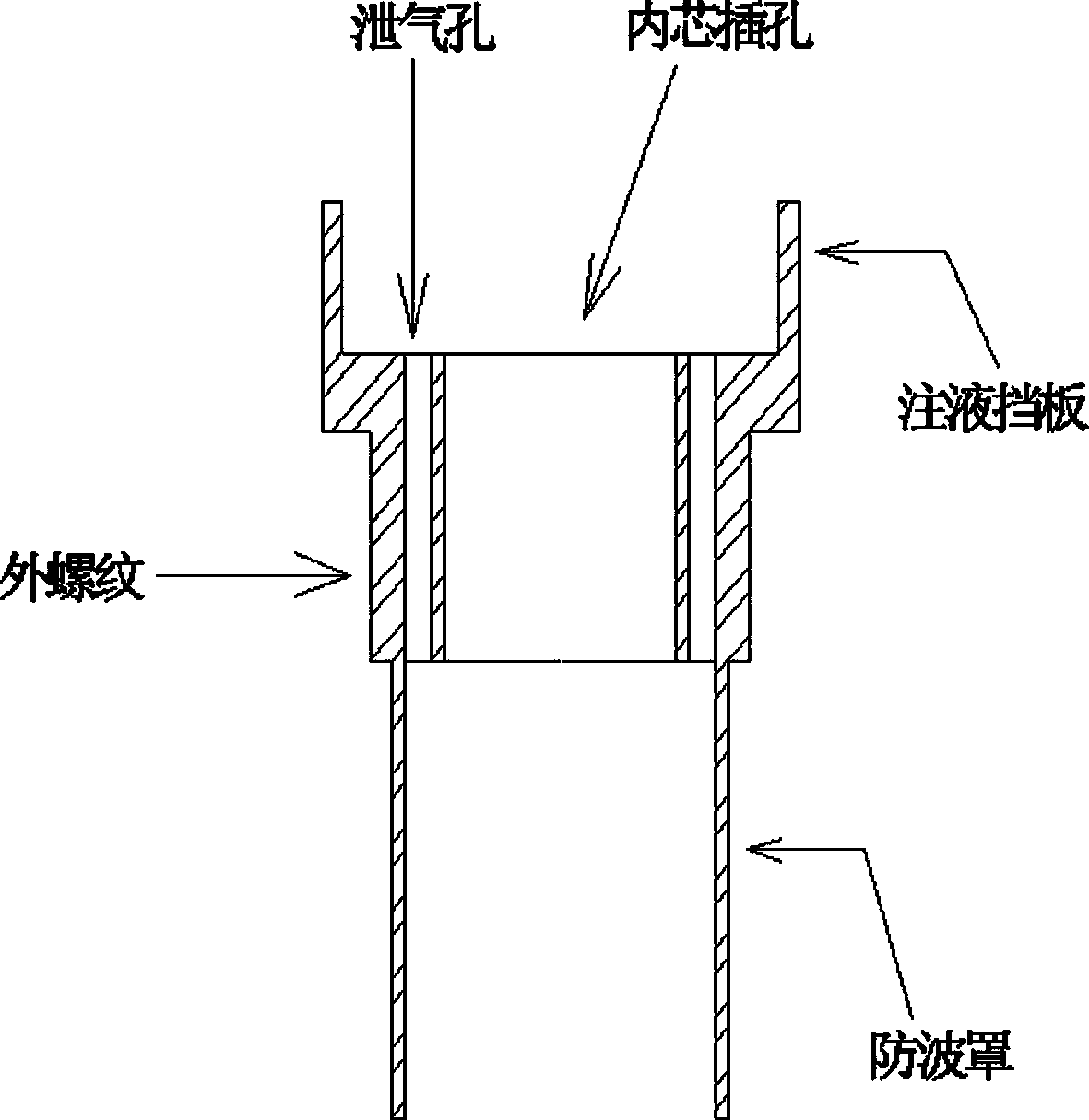

[0024] root tree Figure 1-Figure 8 As shown, a temperature liquid level sensor for a lead-acid battery includes a sensor inner core 2 arranged in a sensor outer cover 1, and the sensor inner core 2 includes a liquid level float 3 and a buckle 4 arranged outside the lower part of the inner core shell 5, and the inner core A temperature sensor 6 and a reed switch 7 are arranged in the inner cavity of the lower part of the shell 5 .

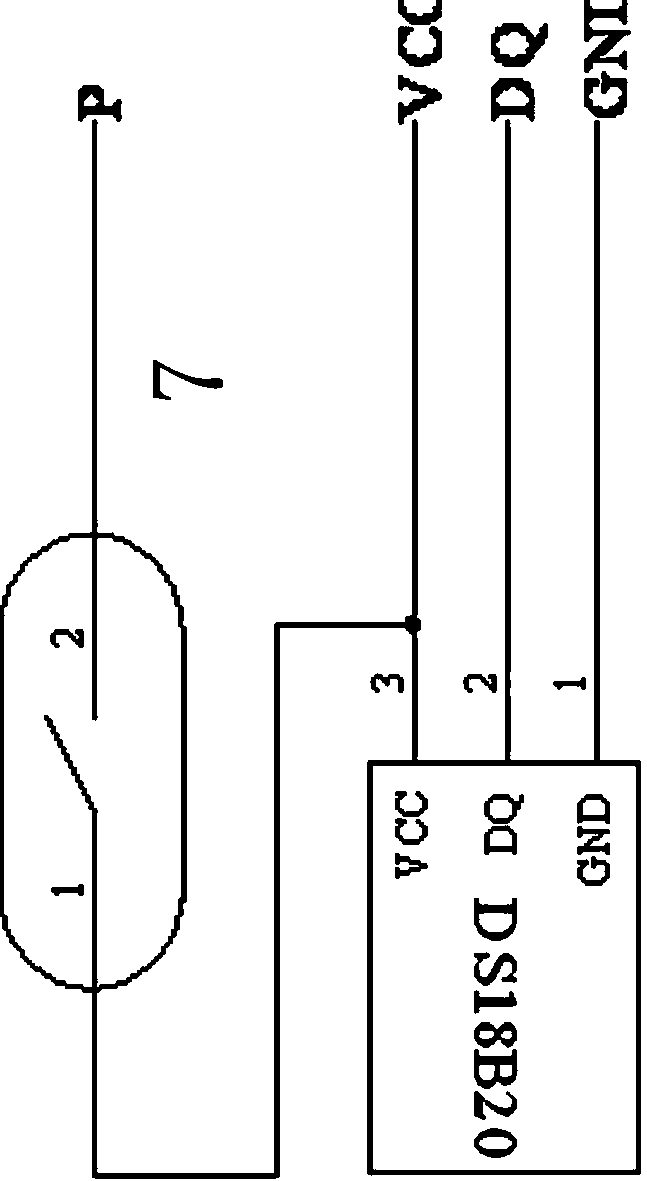

[0025] The wiring method of the sensor cable is: VCC cable is connected to one end of the reed switch, VCC cable is connected to 3 pins of DS18B20, DQ cable is connected to 2 pins of DS18B20, GND cable is connected to 1 pin of DS18B20, P cable is connected to the reed the other end of the tube.

[0026] The sensor outer cover 1 and the inner core shell 5 are both made of polytetrafluoroethylene, and the cable is made of ultra-fine four-core shielded wire. The reed switch 7 and DS18B20 are epoxy-coated from the potting port of the sensor inner core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com