A kind of fiber-reinforced pipe for mine and its preparation method

A fiber reinforced, mine technology, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of high antistatic requirements and flame retardant requirements, inability to use underground mines, inconvenient installation and transportation, etc., to ensure flame retardant. The effect of improving the stability and antistatic property, rigidity and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] A preparation method of a fiber reinforced pipe used in a mine, the preparation method is as follows:

[0027] (1) Equipped with toughening agent, nano-titanium dioxide and ABS resin are mixed in a weight ratio of 1:1.5 to prepare the toughening agent;

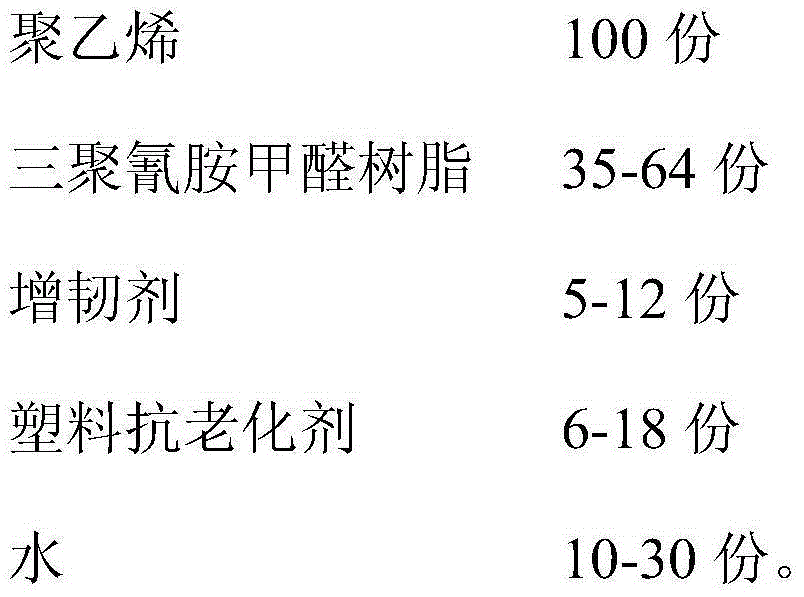

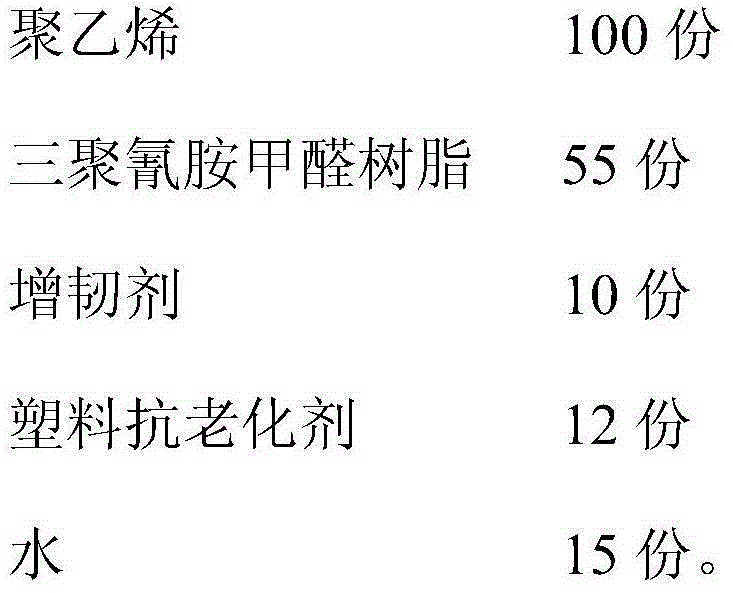

[0028] (2) Add 100 parts by weight of polyethylene, 55 parts of melamine formaldehyde resin, 10 parts of toughening agent, 12 parts of plastic anti-aging agent and 15 parts of water into the extruder, and extrude the inside Liner, the extrusion temperature is 120-155℃;

[0029] (3) After mixing the aromatic polyamide fiber and glass fiber uniformly in a weight ratio of 1:1.5, add it to the winding machine, and wind the mixed fiber evenly and across the outer peripheral surface of the liner tube to form a fiber layer. Rotation speed root is 220 rpm;

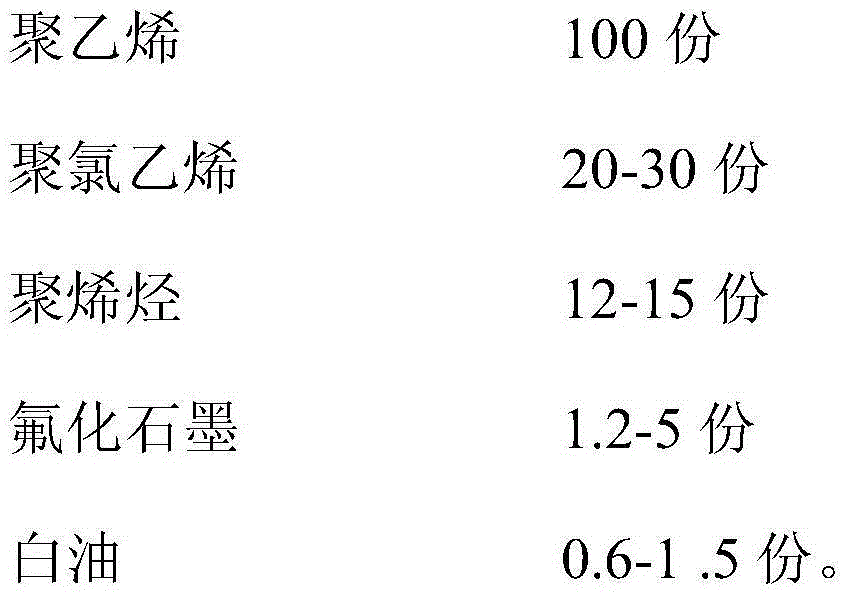

[0030] (4) Add 100 parts by weight of ethylene, 25 parts of polyvinyl chloride, 12 parts of polyolefin, 2 parts of fluorinated graphite, and 0.8 parts of white oil into the extrud...

example 2

[0033] A preparation method of a fiber reinforced pipe used in a mine, the preparation method is as follows:

[0034] (1) Equipped with a toughening agent, nano-titanium dioxide and ABS resin are mixed in a weight ratio of 1:2 to prepare the toughening agent;

[0035] (2) Add 100 parts by weight of polyethylene, 49 parts of melamine formaldehyde resin, 12 parts of toughening agent, 16 parts of plastic anti-aging agent and 20 parts of water into the extruder, and extrude the inside Liner, the extrusion temperature is 135℃;

[0036] (3) After mixing the aromatic polyamide fiber and the glass fiber uniformly in a weight ratio of 1:2, add it to the winding machine, and wind the mixed fiber evenly and across the outer peripheral surface of the inner lining tube to form a fiber layer. Rotation speed root is 220 rpm;

[0037] (4) Add 100 parts by weight of ethylene, 28 parts of polyvinyl chloride, 14 parts of polyolefin, 3 parts of fluorinated graphite, and 1.2 parts of white oil into the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com