A kind of method for reclaiming copper and nickel from copper-nickel-based alloy scrap

A waste recycling, copper-nickel-based technology, applied in the field of comprehensive utilization of resources, can solve the problems of cumbersome, complex process, low purity of copper and nickel products, and achieve the effects of simple process, high comprehensive utilization, and good prospects for industrial promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

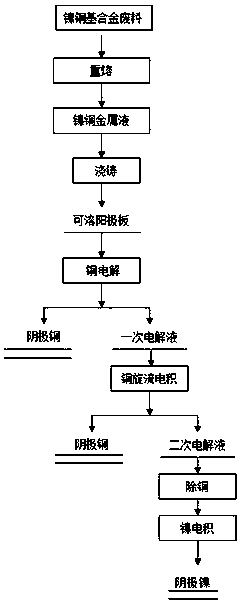

[0020] Such as figure 1 Shown, the copper-nickel-based alloy scrap reclaims the method for copper, nickel, and its concrete steps are as follows:

[0021] (1) First, the copper-nickel-based alloy scrap is heated to a molten state and kept for 0.5 hours, then the copper-nickel metal liquid is cast into a soluble anode plate, and then the soluble anode plate is used as the anode, the stainless steel plate is used as the cathode, and copper sulfate is used as the electrolyte. The control tank voltage is 1.4V and the current density is 160A / m at the same time 2 Under the condition of electrolysis until the concentration of copper ions in the electrolyte is 5g / L, copper can be prepared on the cathode, wherein the mass percentages of copper and nickel in the copper-nickel-based alloy waste are 98% and 2% respectively, and the temperature of the copper-nickel-based alloy waste is increased. The temperature is 1500°C, the size of the soluble anode plate is 670×870×10mm, the size of t...

Embodiment 2

[0027] Such as figure 1 Shown, the copper-nickel-based alloy scrap reclaims the method for copper, nickel, and its concrete steps are as follows:

[0028] (1) First, the copper-nickel-based alloy waste is heated to a molten state and kept for 2.5 hours, and then the copper-nickel metal liquid is cast into a soluble anode plate, and then the soluble anode plate is used as the anode, the stainless steel plate is used as the cathode, and copper sulfate is used as the electrolyte. The control tank voltage is 3.0V and the current density is 320A / m at the same time 2 Electrolysis under the conditions until the concentration of copper ions in the electrolyte is 30g / L, that is, copper can be prepared on the cathode, the mass percentages of copper and nickel in the copper-nickel-based alloy waste are 30% and 70% respectively, and the heating temperature of the copper-nickel-based alloy waste is The temperature is 1650°C, the size of the soluble anode plate is 700×900×10mm, the size of...

Embodiment 3

[0034] Such as figure 1 Shown, the copper-nickel-based alloy scrap reclaims the method for copper, nickel, and its concrete steps are as follows:

[0035] (1) Firstly, the copper-nickel-based alloy waste is heated to a molten state and kept for 1 hour, and then the copper-nickel metal liquid is cast into a soluble anode plate, and then the soluble anode plate is used as the anode, the stainless steel plate is used as the cathode, and copper sulfate is used as the electrolyte. The cell voltage is 2.5V and the current density is 250A / m at the same time 2 Under the condition of electrolysis until the concentration of copper ions in the electrolyte is 18g / L, copper can be prepared on the cathode, wherein the mass percentages of copper, nickel and iron in the copper-nickel-based alloy scrap are 45%, 35% and 20% respectively, and the copper The heating temperature of nickel-based alloy waste is 1600°C, the size of the soluble anode plate is 720×900×10mm, the size of the electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com