Method for increasing metal ore leaching rate, and special strain thereof

A metal and ore technology, applied in the field of improving metal ore leaching rate, method and special bacterial strain, can solve the problems such as unclear action of Alicyclobacillus, achieve the goal of increasing leaching rate, good growth, and improving leaching efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

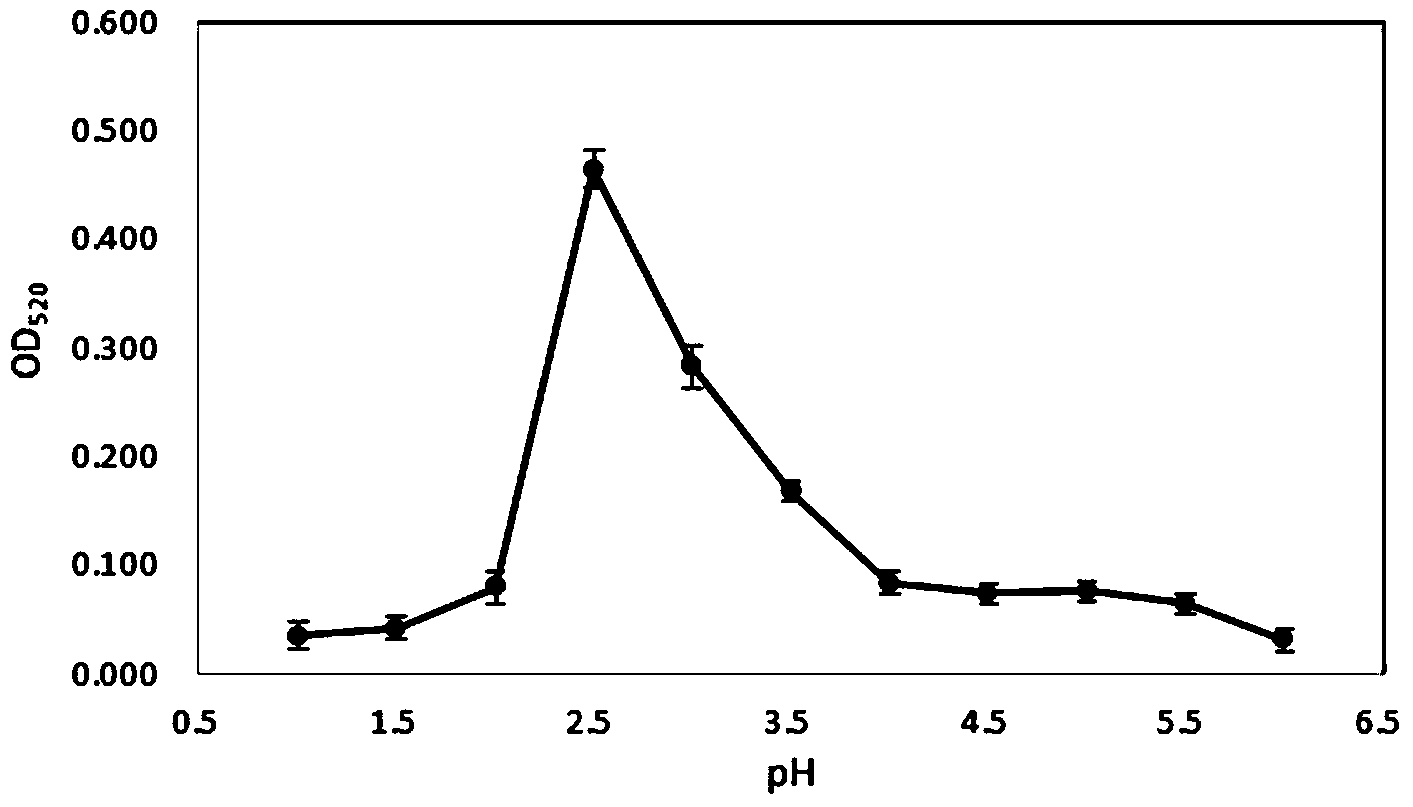

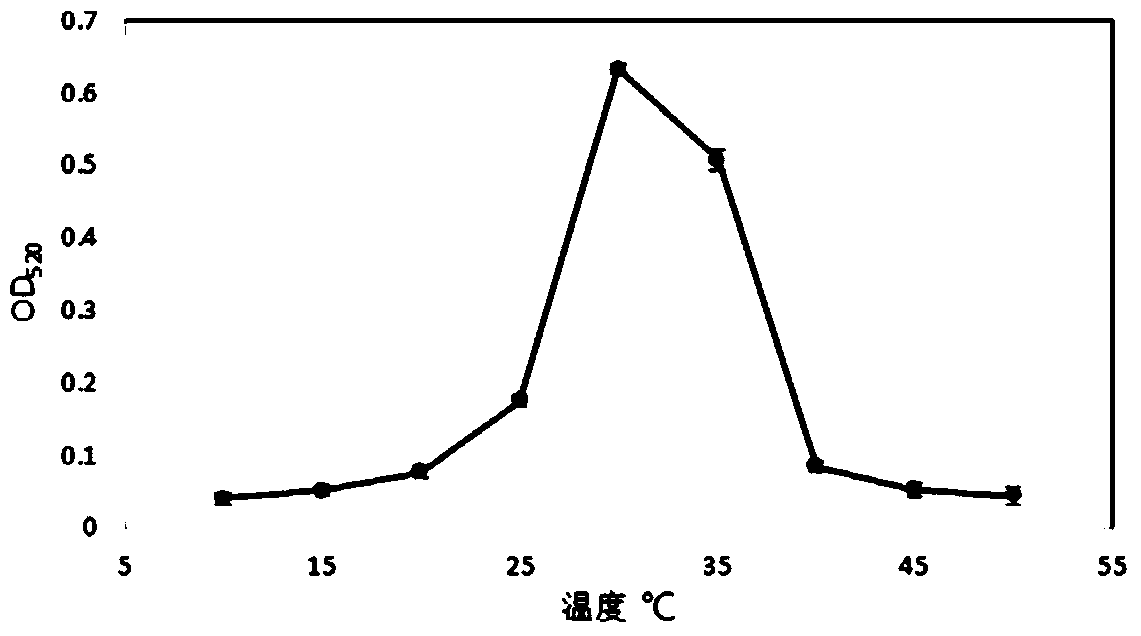

[0049] Example 1. Isolation and Identification of Alicyclobacillus sp. SJ-68 Bacteria

[0050] 1. Separation

[0051] The strain of the present invention is isolated and purified from muddy water samples around sulfur-rich hot springs in Tengchong County, Yunnan Province, China, and the separation and purification time is September 18, 2012.

[0052] The enrichment of microorganisms is carried out by adding 100mL of autotrophic medium into a 250mL shake flask, weighing 5 grams of hot spring mud water sample and adding it into the sterilized autotrophic medium, and enriching and culturing at 30°C. After culturing for one week, the bacterial growth was detected under a microscope. After three times of enrichment, the enrichment medium was diluted 10 times, and 0.2 mL of the diluted medium was spread on a plate to separate single clones. The solid medium was added with 7 g / L Gelrite glue on the basis of the liquid medium. Through multiple streak cultures, a monoclonal strain wa...

Embodiment 2

[0086] Example 2. Application of Alicyclobacillus sp. SJ-68CGMCC No.7682

[0087] 1. Application of SJ-68 combined with Acithiobacillus aldus.SM-1 in dissolving copper sulfide ore

[0088] 1. Preparation of raw materials and inoculation medium

[0089] Yeast extract was purchased from Oxoid Ltd, catalog number 1039501.

[0090] The ore composition of copper sulfide ore: Cu0.8%, Fe2.5%, S3%; % means mass percentage.

[0091] Before the experiment, pass the copper sulfide ore through a 300-mesh sieve (the average particle size is 48 μm), and then use 1:1 (volume ratio of acid and water) H 2 SO 4 The aqueous solution is acidified until the pH value of the obtained acidified solution is maintained between 1.8-2.0 for 24 hours; it takes about 3-5 days; and then the acidified copper sulfide ore is sterilized by ultraviolet light.

[0092] The Alicyclobacillus sp. SJ-68CGMCC No.7682 culture solution used for ore leaching inoculation is to cultivate Alicyclobacillus sp. SJ-68CGMCC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com