Preparation method of esomeprazole trihydrate

A technology for esomeprazole magnesium trihydrate and esomeprazole sodium is applied in the field of preparation of esomeprazole magnesium trihydrate, and can solve the problem of being unsuitable for industrial scale production, excessive residual solvent and high cost The problem is to achieve the effect of improving chemical purity and optical purity, product content and product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

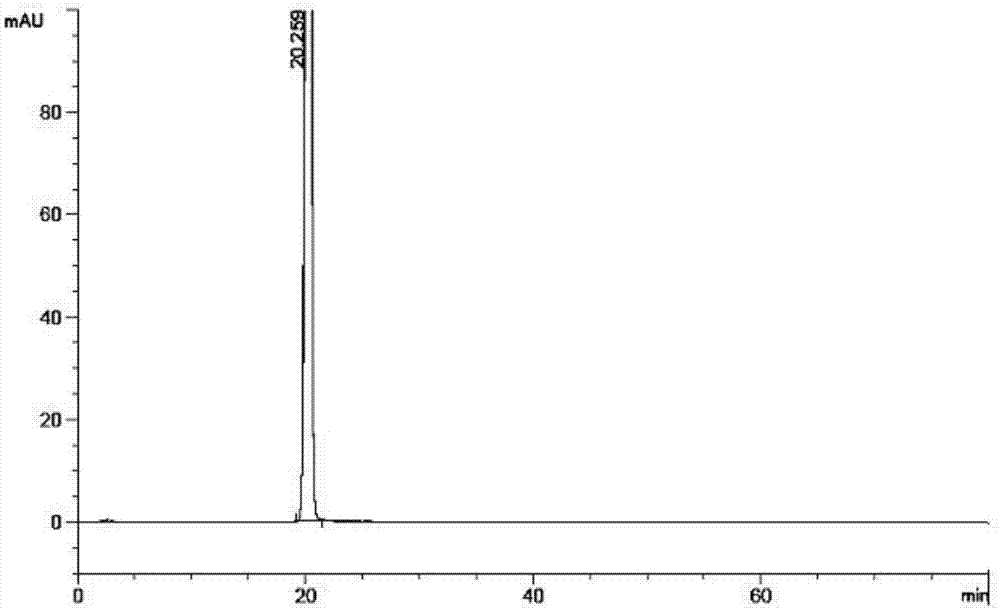

Image

Examples

Embodiment 1

[0046] Embodiment 1 This embodiment is the preparation embodiment of esomeprazole magnesium trihydrate

[0047] Step (1) preparation of intermediate 1

[0048] Add 150ml of absolute ethanol and 3.0g of sodium hydroxide into a 250ml three-necked flask, heat and stir at 25-30°C for 2 hours, and then add 20.0g of omeprazole. Add 4.1 g of disodium hydrogen phosphate, continue stirring for 1 hour, transfer the reaction solution into a 250 ml single-necked bottle, evaporate to dryness in a water bath at 35-40 °C under reduced pressure, add 200 ml of acetone to the residue, stir and analyze at 10-15 °C crystal. After filtration, the filter cake was dried under reduced pressure at 35-40°C to obtain intermediate 1 with a yield of 98%, a purity of 99.914%, and a pH value of 10.8. The molar ratio of disodium hydrogen phosphate to omeprazole is 1:2.

[0049] Step (2) preparation of intermediate 2

[0050] Intermediate 1 prepared in step (1) was added with 12 g of titanium isopropoxide...

Embodiment 2

[0058] Embodiment 2 This embodiment is the preparation embodiment of esomeprazole magnesium trihydrate

[0059] Step (1) preparation of intermediate 1

[0060] Add 150ml of absolute ethanol and 3.0g of sodium hydroxide into a 250ml three-necked flask, heat and stir at 25-30°C for 3 hours, and then add 20g of omeprazole. Add 8.2 g of disodium hydrogen phosphate, continue to stir for 1.5 hours, transfer the reaction solution into a 250 ml single-necked bottle, evaporate to dryness under reduced pressure in a water bath at 35 to 40 ° C, add 200 ml of acetone to the residue and stir at 10 to 15 ° C to analyze crystal. After filtration, the filter cake was dried under reduced pressure at 35-40°C to obtain Intermediate 1 with a yield of 97%, a purity of 99.89%, and a pH value of Intermediate 1 of 10.7. The molar ratio of disodium hydrogen phosphate to omeprazole is 1:1.

[0061] Step (2) preparation of intermediate 2

[0062] With embodiment 1.

[0063] Step (3): Preparation of...

Embodiment 3

[0069] Embodiment 3 This embodiment is the preparation embodiment of esomeprazole magnesium trihydrate

[0070] Step (1) preparation of intermediate 1

[0071] With embodiment 1.

[0072] Step (2) preparation of intermediate 2

[0073] With embodiment 1.

[0074] Step (3): Preparation of Intermediate 3

[0075] With embodiment 1.

[0076] Step (4): Preparation of Intermediate 4

[0077] Add 3.5g of sodium hydroxide and 200ml of ethyl acetate to 324.2g of the intermediate obtained in step (3), stir for 2 hours with 200ml of purified water, separate layers, acidify the alkaline aqueous layer, extract with ethyl acetate, dry, evaporate under reduced pressure The crude product of intermediate 4 esomeprazole was dried; the molar ratio of sodium hydroxide to intermediate 3 was 6:1; the yield of intermediate 4 was 97%, and the HPLC purity was 99.811%.

[0078] Step (5): Add 7.74g of esomeprazole, 0.89g of sodium hydroxide, and 50ml of absolute ethanol prepared in step (4) into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com