Composite brick and preparation method thereof

A composite brick and brick layer technology, applied in the field of refractory materials, can solve problems such as increased heat dissipation, high product cost, and potential safety hazards in the use of ladles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides the preparation method of above-mentioned composite brick, comprises the following steps:

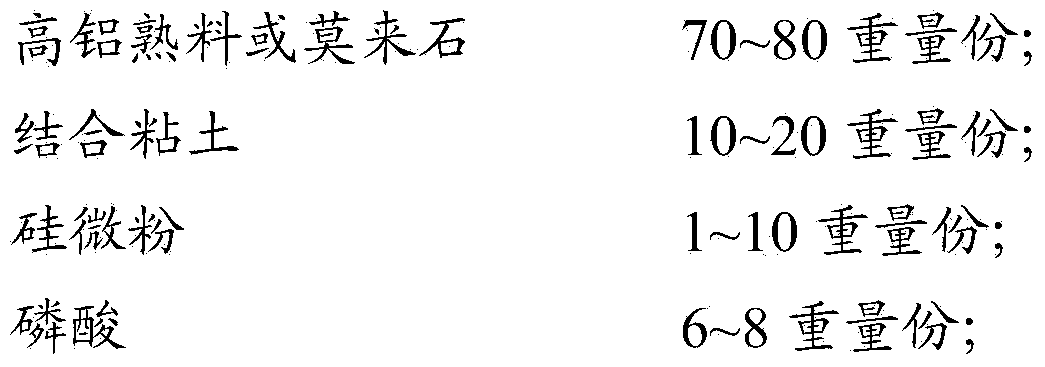

[0039] A) Hot-end aluminum brick layer ingredients: 70-80 parts by weight of high-alumina clinker or mullite, 10-20 parts by weight of bonded clay, 1-10 parts by weight of silica powder, 6-8 parts by weight of Phosphoric acid is mixed with 2 to 4 parts by weight of water to obtain hot-end aluminum brick layer mud;

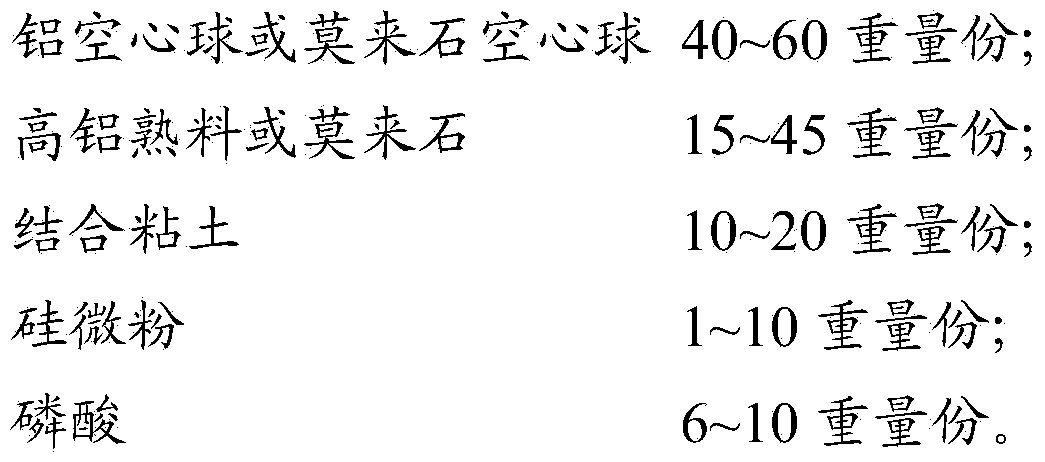

[0040] Ingredients for the cold-end hollow spherical brick layer: 40-60 parts by weight of aluminum hollow spheres or mullite hollow spheres, 15-45 parts by weight of high-alumina clinker or mullite, 10-20 parts by weight of bonded clay, 1-10 parts by weight of silicon micropowder, 6-10 parts by weight of phosphoric acid and 2-4 parts by weight of water are mixed to obtain the cold-end hollow spherical brick layer mud;

[0041] B) Provide a mold with a partition, add the hot-end aluminum brick layer mud and the cold-end hollow sphe...

Embodiment 1

[0052] 1.1 Add 75 parts by weight of first-grade high-alumina clinker particles into the 800 mixing mill, then add 8 parts by weight of phosphoric acid, and mix and grind for 2 minutes, then add 14 parts by weight of bonded clay and 3 parts by weight of silicon micropowder, and mix and grind After 15 minutes, add 3 parts by weight of water, mix for 5 minutes, and discharge to obtain hot-end aluminum brick layer mud.

[0053] 1.2 Put 40 parts by weight of alumina hollow spheres and 37 parts by weight of first-grade high-alumina clinker into the 800 mixer, then add 10 parts by weight of phosphoric acid, mix and mill for 2 minutes, then add 20 parts by weight of bonded clay and 3 Parts by weight of silicon micropowder were mixed and milled for 15 minutes, then 3 parts by weight of water were added, mixed for 5 minutes, and then discharged to obtain the cold-end hollow spherical brick layer mud.

[0054] 1.3 Provide a mold with a partition, the partition is located at one-third of...

Embodiment 2

[0057] 2.1 Add 75 parts by weight of first-grade high-alumina clinker particles into the 800 mixing mill, then add 8 parts by weight of phosphoric acid, and mix and grind for 2 minutes, then add 14 parts by weight of bonded clay and 3 parts by weight of silicon micropowder, and mix and grind After 15 minutes, add 3 parts by weight of water, mix for 5 minutes, and discharge to obtain hot-end aluminum brick layer mud.

[0058] 2.2 Add 45 parts by weight of alumina hollow spheres and 32 parts by weight of first-grade high-alumina clinker into the 800 mixer, then add 10 parts by weight of phosphoric acid, and mix for 2 minutes, then add 20 parts by weight of bonded clay and 3 Parts by weight of silicon micropowder were mixed and milled for 15 minutes, then 3 parts by weight of water were added, mixed for 5 minutes, and then discharged to obtain the cold-end hollow spherical brick layer mud.

[0059] 2.3 Provide a mold with a partition, the partition is located at one-third of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com