Automatic U-shaped groove forming system for factory-like prefabrication

An automatic forming and U-shaped groove technology, which is applied in ceramic forming machines, forming conveyors, ceramic forming workshops, etc., can solve the problems of large-scale factory production, rough surface of U-shaped channel components, and short concrete vibration time and other issues, to achieve good market prospects, simple and easy construction, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

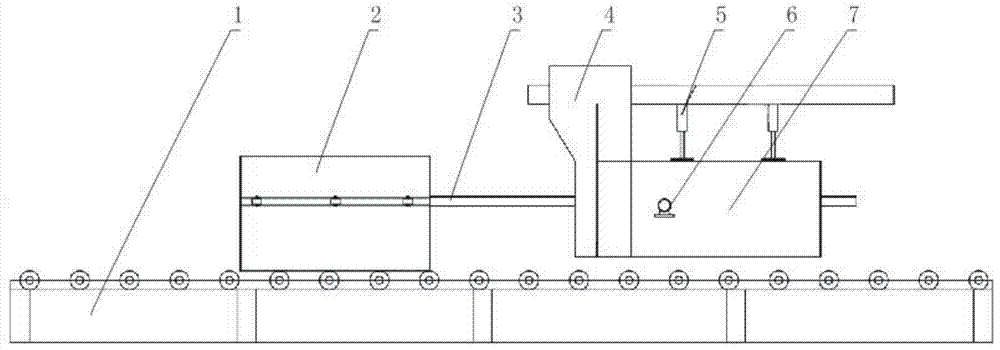

[0026] A factory prefabricated U-shaped groove automatic forming system, including belt conveyor 1, unloading device 4, outer mold guide beam 3, mold skin 2, inner mold 7, high-frequency vibrating screen 6, lifting cylinder 5, belt type The middle part above the conveyor is fixed with a feeding device,

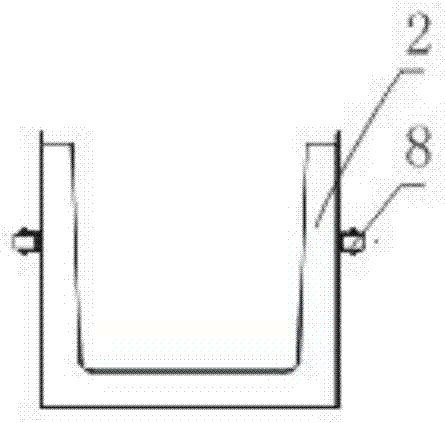

[0027] The outer mold guide beams are installed symmetrically on both sides above the belt conveyor in front of the unloading device, and the mold skin to be processed is placed on the belt conveyor between the outer mold guide beams on both sides. A plurality of guide bearings 8 are evenly spaced on the outer wall of the mold skin corresponding to the position of the guide beam of the outer mold;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com