A kind of preparation method of high-strength binder-free hierarchical porous composite ZSM-5 catalyst

A ZSM-5, binder-free technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex experimental process, silicon-aluminum ratio, mechanical strength and insufficient experimental operation, etc. Achieve the effects of low waste liquid generation, simple and easy synthesis method, and high crushing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

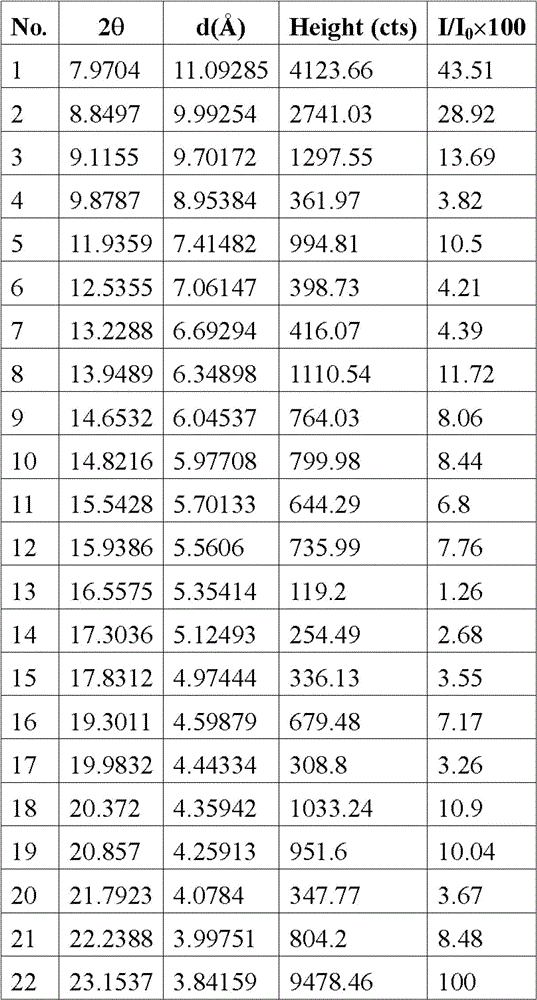

[0039] Synthesize ZSM-5 molecular sieve according to literature method as reference sample (VerifiedSynthesisofZeoliticMaterials2 nd Ed, Elsevier, 2001, 198-199), recorded as sample 1#, its XRD results are shown in Table 1, and the XRF elemental composition and nitrogen physical adsorption results are shown in Table 2.

[0040] XRD result of table 1 sample 1#

[0041]

[0042]

[0043] Table 2 Composition of sample 1# and nitrogen physical adsorption results

[0044]

[0045] a Analysis by XRF method

Embodiment 2

[0047] The types and performance parameters of the mesoporous silica precursors used are shown in Table 3.

[0048] Table 3 Types and performance parameters of mesoporous silica precursors

[0049]

[0050] Concrete preparation process is as follows:

[0051] (a) Immerse the mesoporous silica precursor (Qingdao Ocean Chemical Co., Ltd., silica gel) in sodium hydroxide, aluminum salt or an aqueous solution of sodium hydroxide and aluminum salt, then dry and roast to obtain solid A.

[0052] (b) Place solid A in a place containing tetrapropylammonium ion (abbreviated as TPA + ) in an aqueous solution and dried to obtain solid B.

[0053] (c) Put the solid B in water vapor or the mixed steam of organic amine and water, and crystallize it at 120-210°C for 10-200h. After the solid is dried and roasted, a high-strength binder-free hierarchical porous composite ZSM can be obtained. -5 catalyst. Table 4 shows the corresponding relationship between the sample number and the type...

Embodiment 3

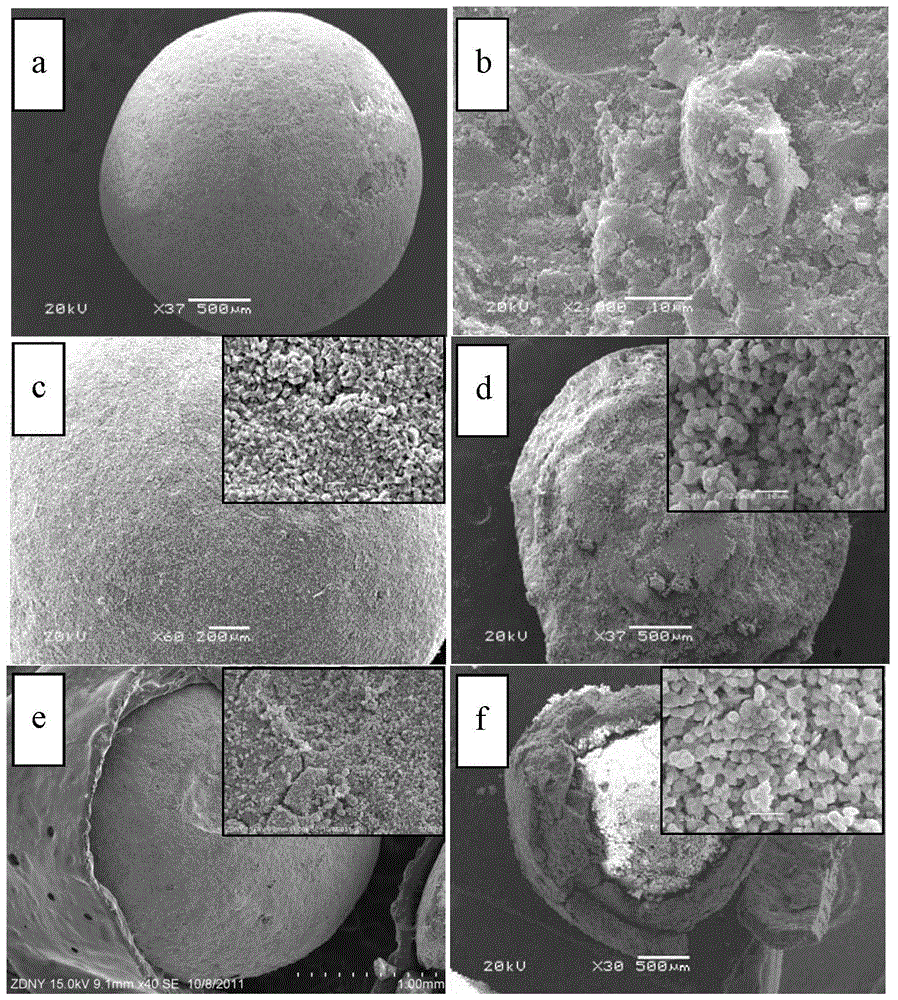

[0057] The samples obtained in Example 2 were characterized by XRD, and the XRD data were similar to those in Table 1, that is, the peak shapes and positions were the same, and the peak intensities were slightly different. Among them, the XRD data of typical sample 2# are shown in Table 5.

[0058] XRD result of table 5 sample 2#

[0059]

[0060]

[0061] Taking sample 1# as reference standard sample, by the strongest diffraction peak intensity (I) among each sample XRD figure in embodiment 2, according to formula:

[0062] ZSM content=(I 样品 / I 1# )×100%

[0063] The content of ZSM-5 in each sample is higher than 95%, as shown in Table 6.

[0064] The crush resistance of each sample in Example 2 was measured on a ZQJ-II intelligent particle strength testing machine of Dalian Intelligent Testing Machine Factory, and the results are shown in Table 6. The crush resistance of samples 2-8# are all higher than 40N / piece. The crush resistance of the product obtained by c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com