Flue gas dust-removing and sulfur-removing system

A desulfurization system and flue gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve problems such as ecological environment damage, environmental pollution, health and life hazards, and achieve simple structure and good desulfurization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

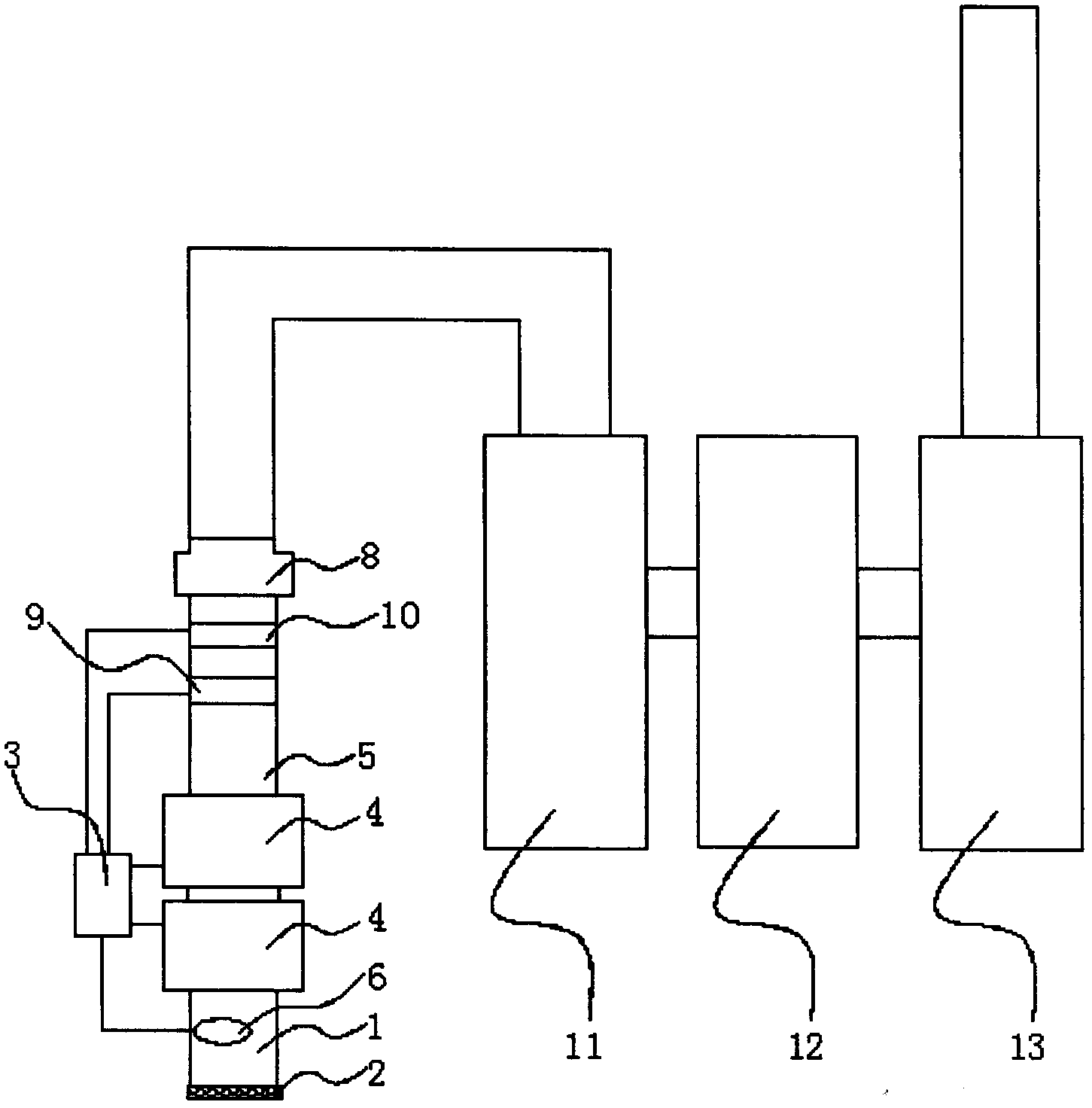

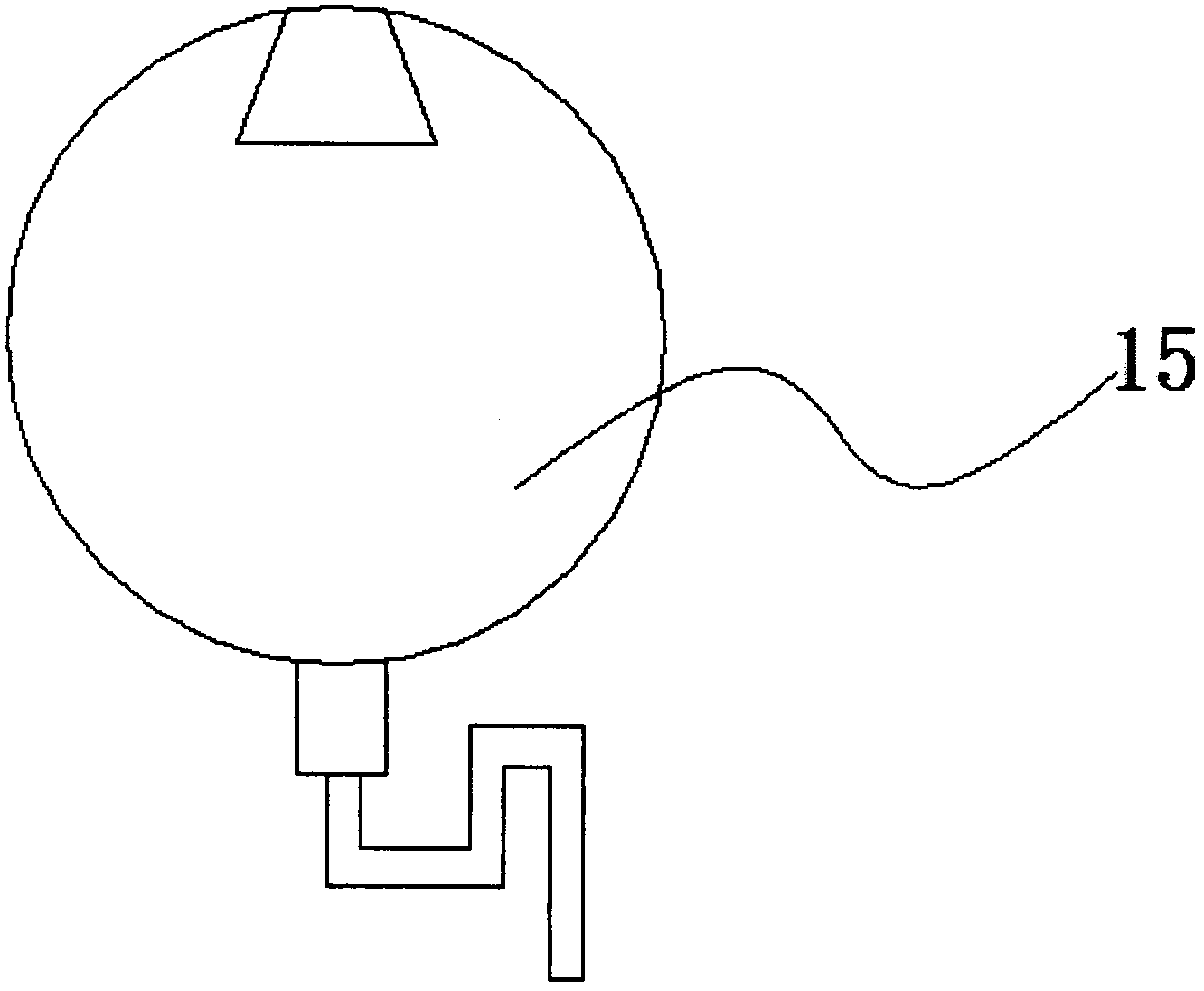

[0017] Such as figure 1 and figure 2 As shown, the flue gas dedusting and desulfurization system in the present invention includes a flue gas pretreatment device and a flue gas desulfurization device connected in sequence through a flue gas pipeline.

[0018] The flue gas pretreatment device is mainly composed of a smoke inlet pipe 1, a controller 3, a primary dust collection filter installed in the smoke inlet pipe 1, a smoke outlet pipe 5, and an electrostatic discharge pipe connected between the inlet and outlet pipes 1 and 5. Dust removal box 4, digital barometer 9, air suction pump 8 and rotor type gas flowmeter 10 are formed, the primary dust collection filter screen 2 is set at the entrance of the smoke inlet pipe 1, and the air suction pump 8 is installed at the outlet of the smoke outlet pipe 5 , the digital barometer 9 and the rotameter gas flowmeter 10 are both installed in the smoke outlet pipe 5 and the signals are output to the controller 3 .

[0019] The flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com