Stable X-crystal-shaped agomelatine tablet and preparation method thereof

A stable technology of agomelatine tablets, applied in the field of pharmaceutical preparations, can solve the problems of inconsistent drug bioavailability, accelerated agomelatine crystal form transformation, infringement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

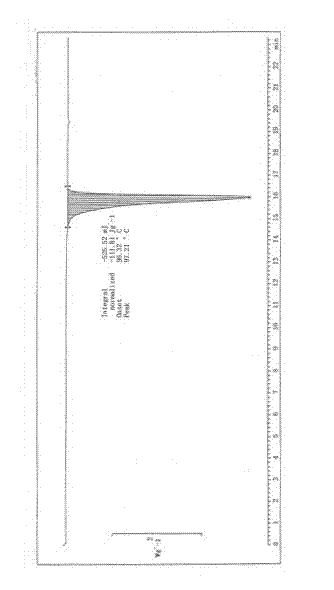

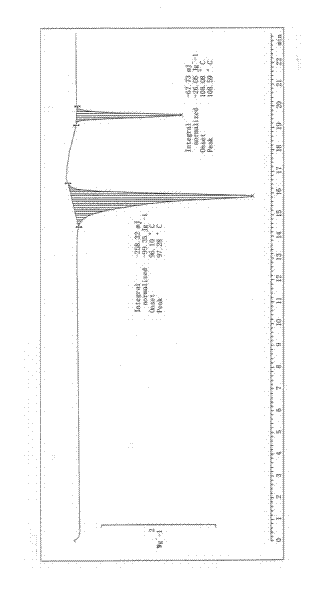

Image

Examples

Embodiment 1

[0140] Agomelatine (Form X 99%) 25g

[0141] water 20ml

[0142] Lactose 102g

[0143] Hypromellose 3g

[0144] Polyvinylpyrrolidone k30 3g

[0145] Cross-linked polyvinylpyrrolidone 13g

[0146] Magnesium Stearate 1.3g

[0147] Stearic acid 2.6g

[0148] Silica 0.3g

[0149] Process: Sift crystalline form X agomelatine according to the above weight for later use; take hydroxypropyl methylcellulose and polyvinylpyrrolidone k30 and stir in water to dissolve, let cool to room temperature, add crystalline form X agomelatine and stir homogeneous; the protective agent containing crystalline X-type agomelatine was obtained for later use; the protective agent containing crystalline X-type agomelatine was added to the mixed granulation containing lactose and part (1 / 2) cross-linked polyvinylpyrrolidone In the machine, after 2 minutes of wet granulation, granulate through a swing granulator (screen 833μm); get wet granules; dry in a fluidized bed (inlet air temperature 45°C, boi...

Embodiment 2

[0151] Agomelatine (more than 90% crystal X) 25g

[0152] water 30ml

[0153] Lactose 102g

[0154] Hydroxypropyl Cellulose 4.5g

[0155] Polyvinylpyrrolidone k30 4.5g

[0156] Croscarmellose Sodium 13g

[0157] Magnesium Stearate 1.3g

[0158] Stearic acid 2.6g

[0159] Silica 0.3g

[0160] Process: Sieve agomelatine crystal X according to the above weight for later use; take hydroxypropyl cellulose and polyvinylpyrrolidone k30 and stir in water to dissolve, let cool to room temperature, add agomelatine crystal X and stir well ; Obtain the protective agent containing crystal X-type agomelatine for later use; add the protective agent containing crystal X-type agomelatine to the mixture containing lactose and part (1 / 2) croscarmellose sodium In the granulator, after 2 minutes of wet granulation, granulate through a swing granulator (screen 833μm); get wet granules; dry in a fluidized bed (inlet air temperature 45°C, boiling bed temperature 30°C), control the moisture con...

Embodiment 3

[0162] Agomelatine (more than 85% crystal X) 25g

[0163] water 30ml

[0164] Lactose 102g

[0165] Hypromellose 4 .5g

[0166] Hydroxypropyl Cellulose 4.5g

[0167] Croscarmellose Sodium 13g

[0168] Magnesium Stearate 1.3g

[0169] Stearic acid 2.6g

[0170] Silica 0.3g

[0171]Process: Sift crystalline form X agomelatine according to the above weight for later use; take hydroxypropyl methylcellulose and polyvinylpyrrolidone k30 and stir in water to dissolve, let cool to room temperature, add crystalline form X agomelatine and stir homogeneous; the protective agent containing crystalline X-type agomelatine was obtained for later use; In the mixing granulator, after wet granulation for 2 minutes, granulate through a swing granulator (screen size 833 μm); wet granules are obtained; dry in a fluidized bed (inlet air temperature 45°C, boiling bed temperature 30°C), control the moisture content of about 2%; whole grain; calculate the yield, add other remaining excipients,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com