Method for preparing lithium iron phosphate membrane electrode

A technology of lithium iron phosphate and thin film electrodes, which is applied in the field of preparation of lithium iron phosphate thin film electrodes, can solve problems such as expensive equipment, and achieve the effects of short synthesis process, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 6.24g of lithium dihydrogen phosphate, 4.79g of nanoscale iron oxide red (M Li :M Fe :M P =1.00:0.98:1.00), 2.0g of glucose, 0.26g of SBR, 25g of alcohol, milled for 6 hours in a planetary ball mill at a ball-to-material ratio of 4:1, to obtain a precursor slurry with a viscosity of 16000-20000Pa·s.

[0034] The slurry is coated on the surface of nickel foam according to the surface density of 2000-5000g / m2, and the coated nickel foam is baked at 80°C for 10h until it is completely dry.

[0035] After the nickel foam was rolled to 1 / 2 of the original thickness, it was sintered under a nitrogen atmosphere at a sintering temperature of 650°C for 12h. A thin film electrode synthesized at one time was prepared.

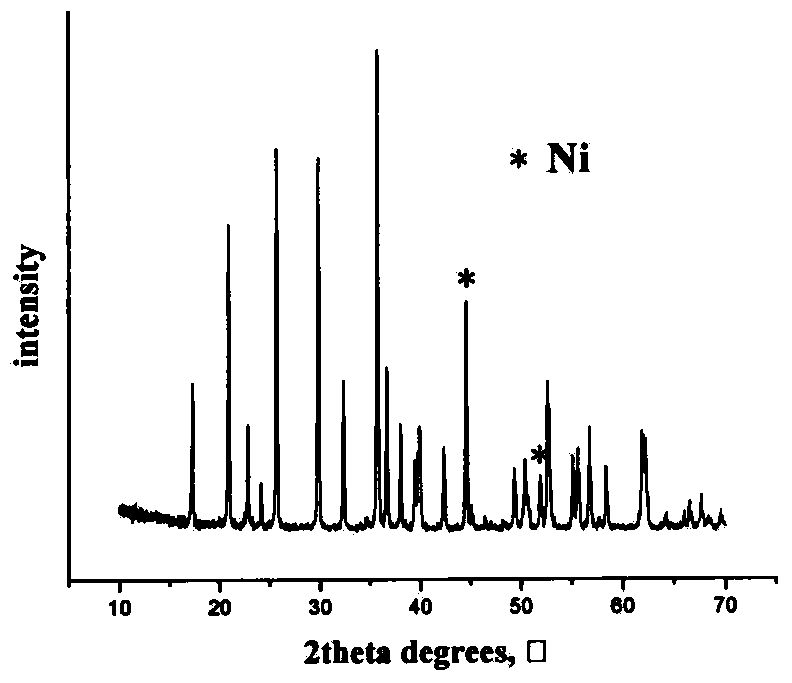

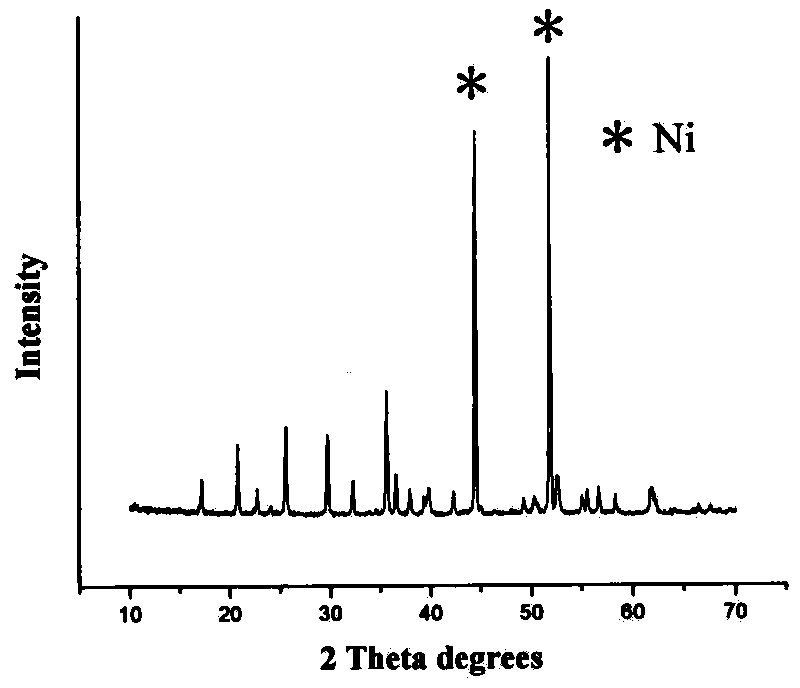

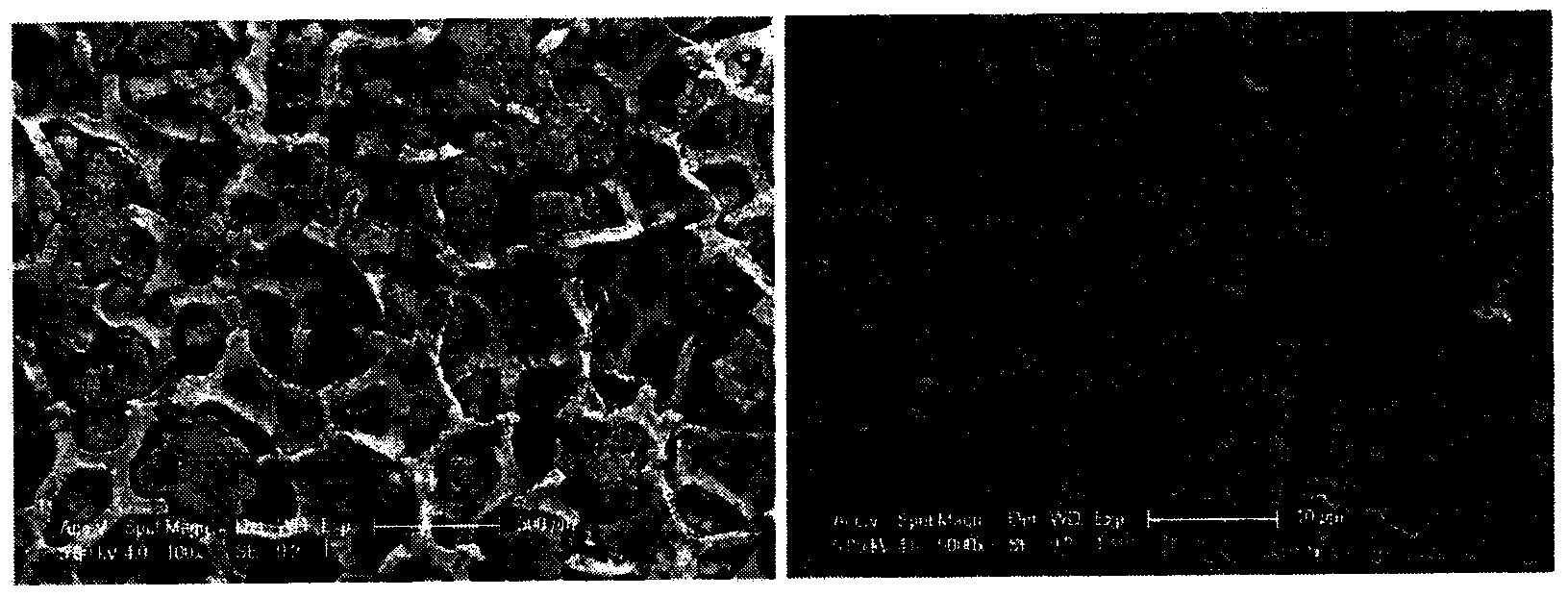

[0036] figure 1 It is the XRD pattern of the powder scraped from the electrode. It can be seen that most of the diffraction peaks of the material can be indexed as orthorhombic lithium iron phosphate cathode materials (JCPDS83-2092), and the diffraction ...

Embodiment 2

[0038] Take by weighing ammonium dihydrogen phosphate 6.291g, iron oxide red 4.9g, lithium carbonate 2.024g, (M Li :M Fe :M P =1.00:0.98:1.00) Glucose 1.82g, CMC 0.25g, deionized water 40g, ball milled in a planetary ball mill for 6h at a ball-to-material ratio of 4:1 to obtain a precursor slurry with a viscosity of 16000-20000Pa·s.

[0039] Put the slurry according to the surface density of 1200-2000g / m 2 Coated on the surface of nickel foam, bake the coated nickel foam at 100°C for 20h until completely dry.

[0040] After rolling the nickel foam to 1 / 2 of the original thickness, it was sintered under a nitrogen atmosphere at a sintering temperature of 700°C for 10 hours. A thin film electrode synthesized at one time was prepared.

Embodiment 3

[0042] Take by weighing iron phosphate 9.23g, lithium carbonate 2.024g, (M Li :M Fe :M P =1.00:1.00:1.02) 2.2g of glucose, 0.2g of PF, and 40g of alcohol were milled for 5 hours in a planetary ball mill at a ball-to-material ratio of 4:1 to obtain a precursor slurry with a viscosity of 16000-20000Pa·s.

[0043]Put the slurry according to the surface density of 1200-2000g / m 2 Coated on the surface of nickel foam, bake the coated nickel foam at 80°C for 10h until it is completely dry.

[0044] Roll the nickel foam to 1 / 2 of the original thickness, and then sinter it under a nitrogen atmosphere at a temperature of 650°C for 6-20 hours. A thin film electrode synthesized at one time was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com