Analysis method and apparatus of ultra pure arsine

An analysis device and a technology for ultra-pure arsine, which are applied to the analysis of ultra-pure arsine and the device field, can solve the problems of unreasonable safety, complicated gas path, long analysis period, etc. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

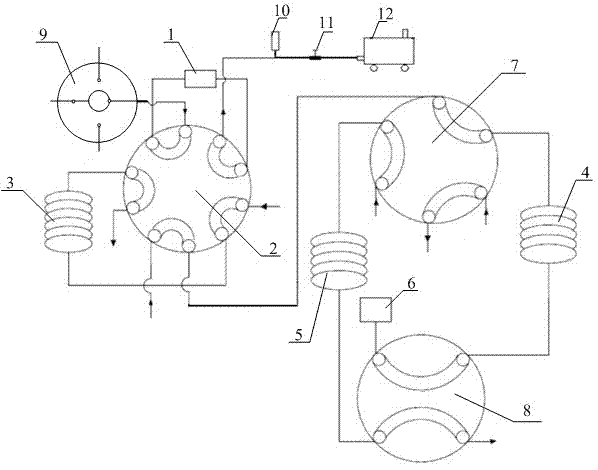

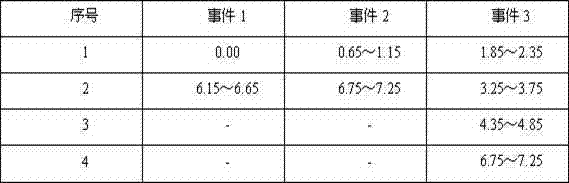

[0037] Ultrapure arsine is used as the sample, and ultrapure helium and nitrogen are used as the auxiliary gas for purging. Connect the ultra-pure arsine sample gas pipeline, 6N helium pipeline, and 6N nitrogen pipeline to the four-way sampling valve 9 respectively, open the diaphragm valve 11, and turn on the molecular pump unit 12 to evacuate to 1×10 -4 ~1×10 -7 Pa, then connect the four-way sampling valve 9 to the 6N helium pipeline, and purge the quantitative tube 1 at a flow rate of 20-50mL / min. After the purging, evacuate the helium in the pipeline to 1×10 -4 ~1×10 -7 Pa, the above operation was repeated three times.

[0038] After the quantitative tube 1 is purged with helium and replaced by negative pressure, connect the four-way sampling valve 9 to the ultra-pure arsine sample gas pipeline, and slowly fill the arsine into the quantitative tube 1 until the pressure sensor 10 shows 0.00MPa , turn off the arsine gas source, and start the operating procedure. Open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com