Kerosene sealing test system with gas-liquid boosting pump

A technology of gas-liquid pressurization and sealing test, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of fluid, and by detecting the appearance of fluid at the leakage point, etc., which can solve the problem of high cost and impact Authenticity of test results, corrosion and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

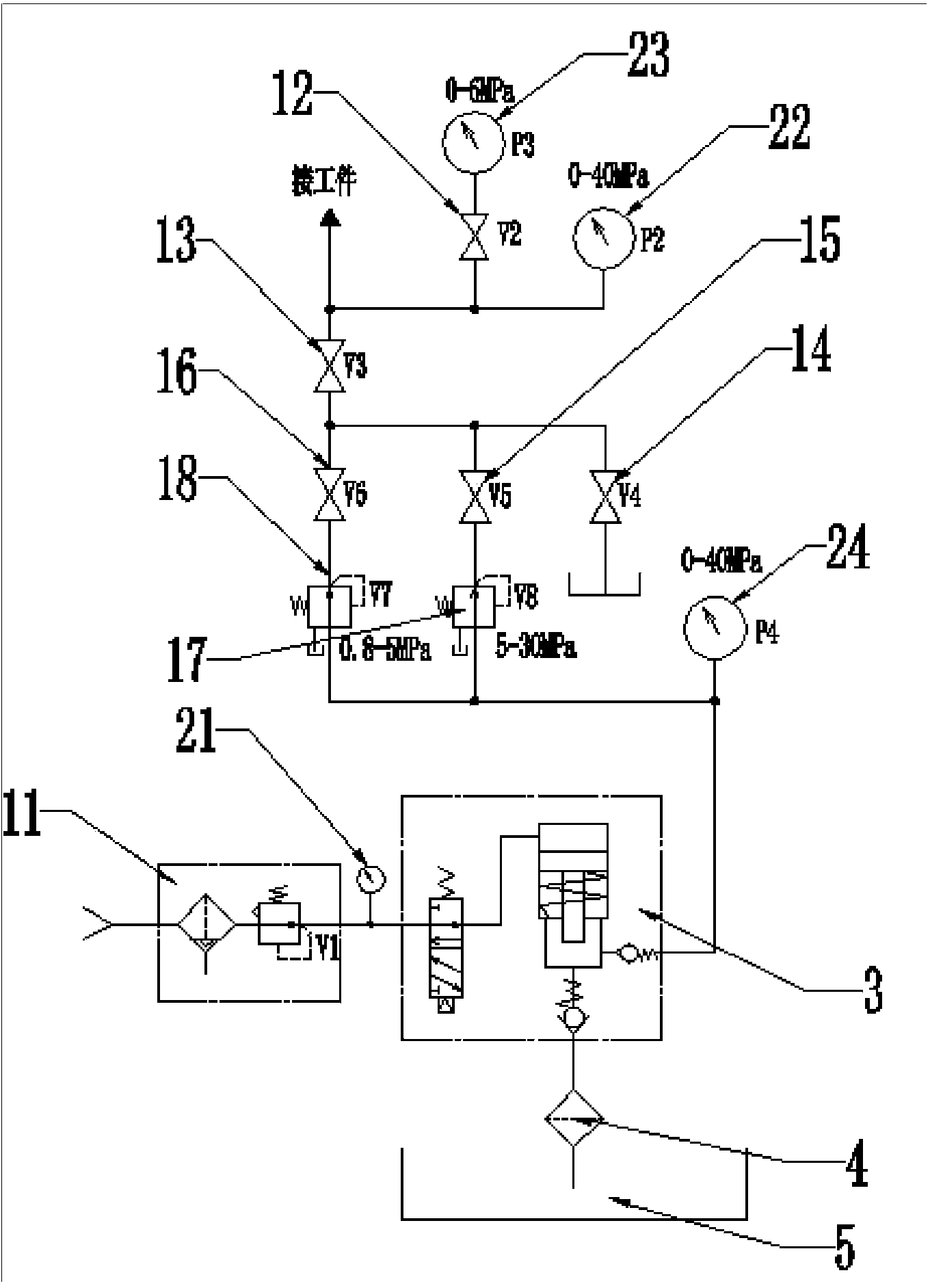

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a kerosene sealing test system with a gas-liquid booster pump includes an air source pressure regulating valve 11, the gas source pressure regulating valve 11 is connected to the gas-liquid booster pump 3, and the gas source pressure regulating valve 11 is connected to the gas-liquid booster pump. An air source pressure gauge 21 is arranged between the pressure pumps 3, the gas-liquid booster pump 3 is connected to the mailbox 5 through the oil suction filter 4, and the output end of the gas-liquid booster pump 3 is connected to the system pressure gauge 24, the high-pressure pressure relief valve 18 and the low-pressure pressure relief valve. Pressure valve 17, high pressure pressure reducing valve 18 are connected with high pressure pressure reducing valve outlet stop valve 15, low pressure pressure reducing valve 17 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com