A kind of preparation method of beaded nanofiber

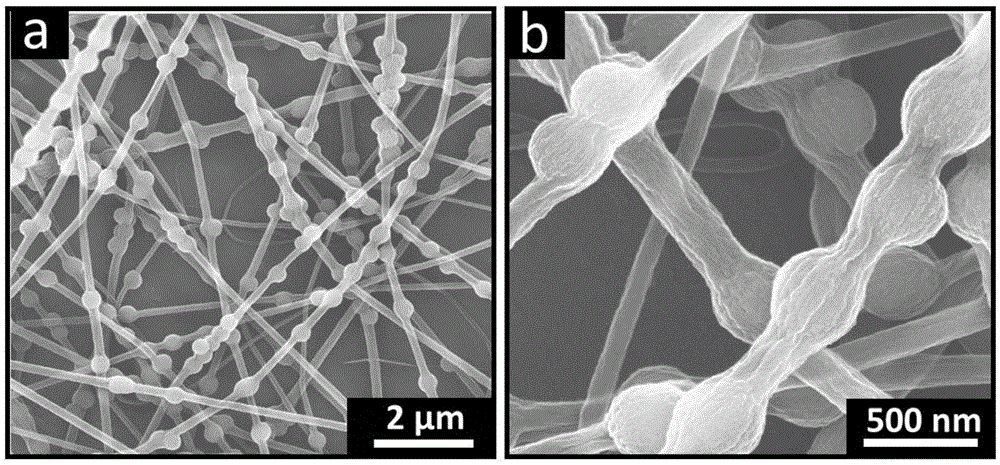

A nanofiber and bead-like technology, which is applied in the field of beaded nanofiber preparation, can solve the problems of poor bonding of inorganic nanoparticles to the interface between inorganic nanoparticles and polymer matrix, uncontrollable position of inorganic nanoparticles, poor dispersion of inorganic nanoparticles, etc. , to achieve the effect of controllable fiber structure, excellent dispersion and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Absolute ethanol, N,N-dimethylformamide (DMF), and tetrahydrofuran (THF) are all produced by Beijing Chemical Plant; silane coupling agent KH550 and cuprous bromide are produced by AJohnsonMattheyCompany; α-bromoisobutyryl bromide It is produced by SIGMA-ALDRICHCompany; pentamethyl-diethyltriamine (PMDETA) is produced by Tixiai (Shanghai) Chemical Industry Development Co., Ltd.; methyl methacrylate is produced by Tianjin Fuchen Chemical Reagent Factory.

[0032] step 1

[0033] Take 1ml of anhydrous acetic acid and 49ml of ethanol and mix them uniformly as a solvent, add 1ml of silane coupling agent KH550, and then add an aqueous solution of silicon dioxide with a particle size of 300nm. After ultrasonic dispersion for 30 minutes to mix the solution uniformly, the reaction was carried out at 50° C. for 24 hours. After the reaction was complete, the solution was taken out and centrifuged in a centrifuge. The rotation speed is 4000r / min, and the separation is performed ...

Embodiment 2

[0043] Prepare SiO according to step 1-step 2 in embodiment 1 2 -Br

[0044] step 3

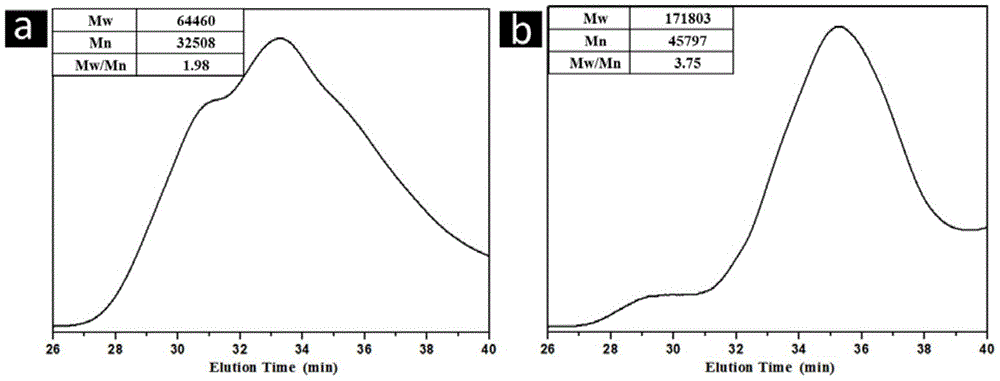

[0045] Take 0.25g of ground SiO 2 -Br was dissolved in 18ml DMF, 8ml MMA, 0.08ml PMDETA were added. Ultrasonic dispersion was performed for 30 minutes, and nitrogen gas was passed through for 20 minutes. Finally, 0.027g of CuBr was added, and the reaction was sealed at 100°C for 60 minutes. After the reaction was completed, the solution was transferred to 500 ml of absolute ethanol for precipitation. After the supernatant has no floating silica, change to 500ml of absolute ethanol for precipitation, and repeat the operation 5 times. After precipitation, centrifuge in a centrifuge. The rotation speed is 4000r / min, and the separation is performed twice, 20 minutes each time, and the washing liquid added is ethanol. After centrifugation, the product was stored in DMF solvent to obtain wet SiO 2 - PMMA, the molecular weight of the grafted PMMA is 171,000.

[0046] step 4

[0047] SiO in...

Embodiment 3

[0051] Prepare SiO according to step 1-step 2 in embodiment 1 2 -Br.

[0052] step 3

[0053] Take 0.25g of ground SiO 2 -Br was dissolved in 18ml of DMF, 8ml of styrene, 0.08ml of PMDETA were added. Ultrasonic dispersion was performed for 30 minutes, and nitrogen gas was passed through for 20 minutes. Finally, 0.027g of CuBr was added, and the reaction was sealed at 100°C for 20 minutes. After the reaction was completed, the solution was transferred to 500 ml of absolute ethanol for precipitation. After the supernatant has no floating silica, change to 500ml of absolute ethanol for precipitation, and repeat the operation 5 times. After precipitation, centrifuge in a centrifuge. The rotation speed is 4000r / min, and the separation is performed twice, 20 minutes each time, and the washing liquid added is ethanol. After centrifugation, the product was stored in DMF solvent to obtain wet SiO 2 -PS, the molecular weight of the grafted PS is 52,000.

[0054] step 4

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com