High-brightness aluminum-alloy polishing section and production process thereof

A production process and technology of aluminum profiles, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of difficult research and development, low surface brightness of profiles, and difficult brightness of 6463 aluminum alloy profiles, and achieve surface corrosion. The effect of fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

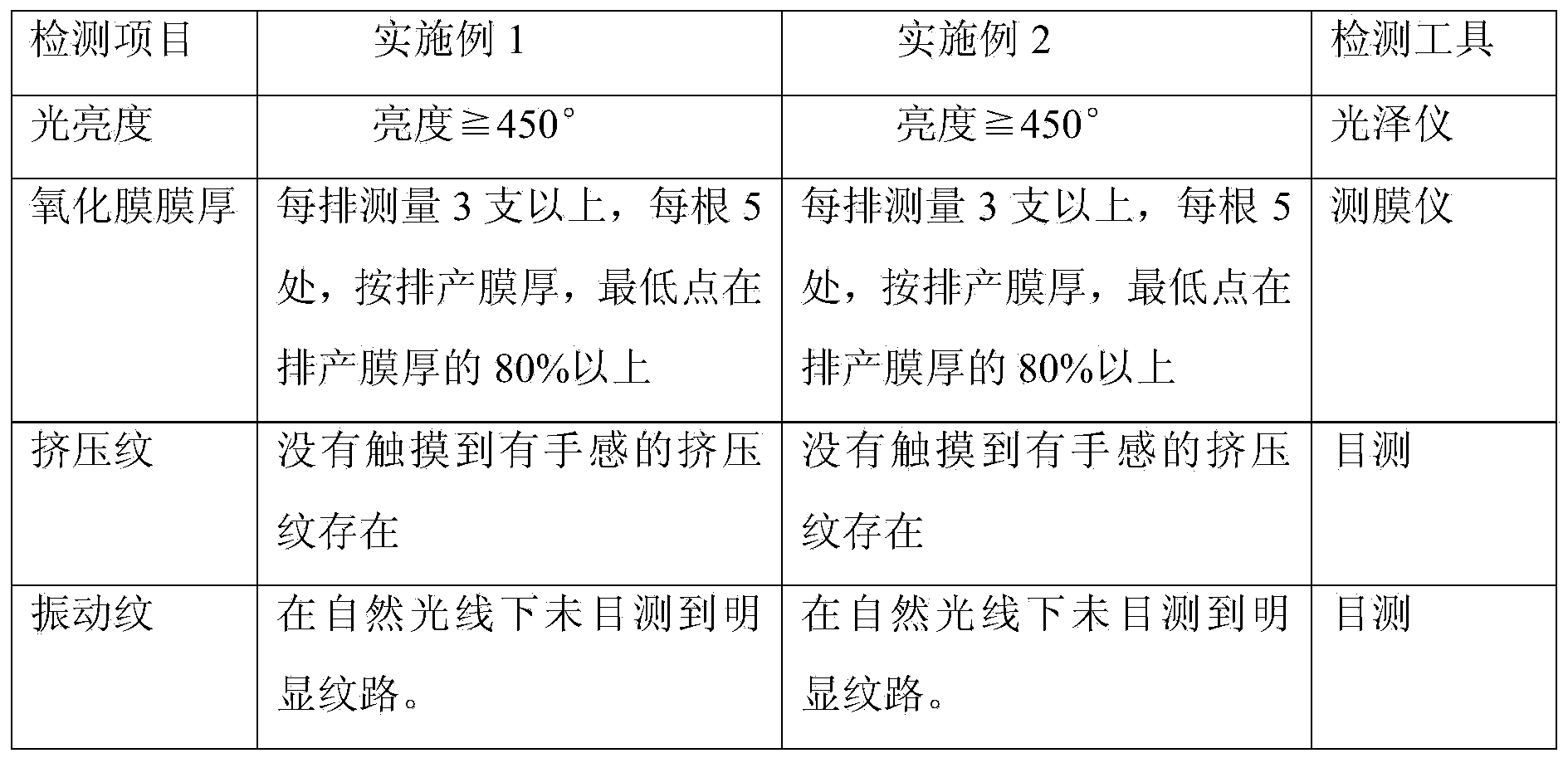

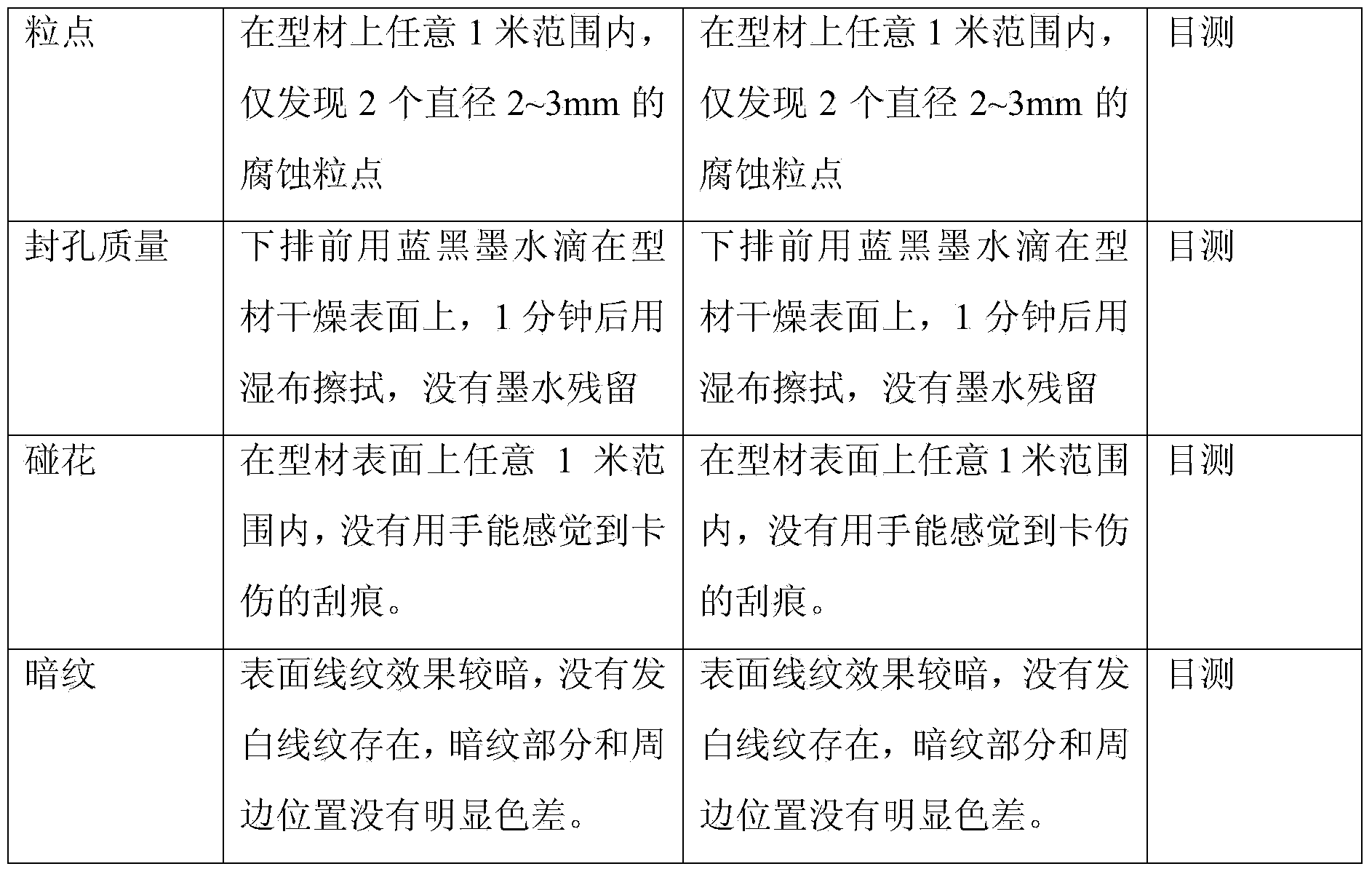

Examples

Embodiment 1

[0028] The aluminum alloy polished profile is prepared by the following steps:

[0029] (1) Melting and casting: smelting molten aluminum and casting the molten aluminum into aluminum rods;

[0030] You can put 80% (mass) of aluminum ingots and the remaining scraps (the scraps left after the aluminum rods are extruded by the extruder) in the melting furnace to melt the aluminum liquid; then add alloys such as silicon and magnesium to it The composition is adjusted so that the mass content of the following chemical elements contained in the molten aluminum obtained from smelting is Si0.32-0.36%, Mg1.2-1.24%, Fe≤0.18, Zn≤0.1, Cu0.04-0.07%, Mn≤ 0.03%, Cr ≤ 0.005%, Ti ≤ 0.05%, Sn ≤ 0.003%, Pb ≤ 0.001%; after refining, slag removal, after the molten aluminum is allowed to stand and its composition is stable, the molten aluminum is cast into aluminum rods.

[0031] (2) Extrusion: Send the aluminum rod cast in step 1 into the extrusion machine, the temperature of the aluminum rod ...

Embodiment 2

[0040] The aluminum alloy polished profile is prepared by the following steps:

[0041] (1) Melting and casting: it is basically the same as that of Example 1, and will not be described in detail;

[0042] (2) Extrusion: Send the aluminum rod cast in step 1 into the extrusion machine, the temperature of the aluminum rod is controlled at 460°C-480°C, and the temperature of the aluminum profile extrusion die in the extrusion machine is controlled at 440-470°C , the aluminum rod is extruded by an extrusion machine to form an aluminum profile, the discharge temperature of the aluminum profile is about 490 ° C, and the wall thickness of the extruded aluminum profile is about 2.0 mm;

[0043] (3) Mechanically polish the aluminum profile with a polishing machine;

[0044] (4) Degreasing: At room temperature, use a solution of 8% AC degreasing agent in the degreasing tank to degrease the aluminum profile, and the treatment time is 1 to 2 minutes;

[0045] (5) Wax removal: Under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com