Environment-friendly oily emulsion release agent and preparation method thereof

A release agent and oil-based technology, which is applied in the field of environmentally friendly oil-based emulsified release agent and its preparation, can solve the problems of difficult to control ratio, brushing effect, high use cost, and concrete pollution, so as to achieve smooth concrete surface, reduce pollution, The effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

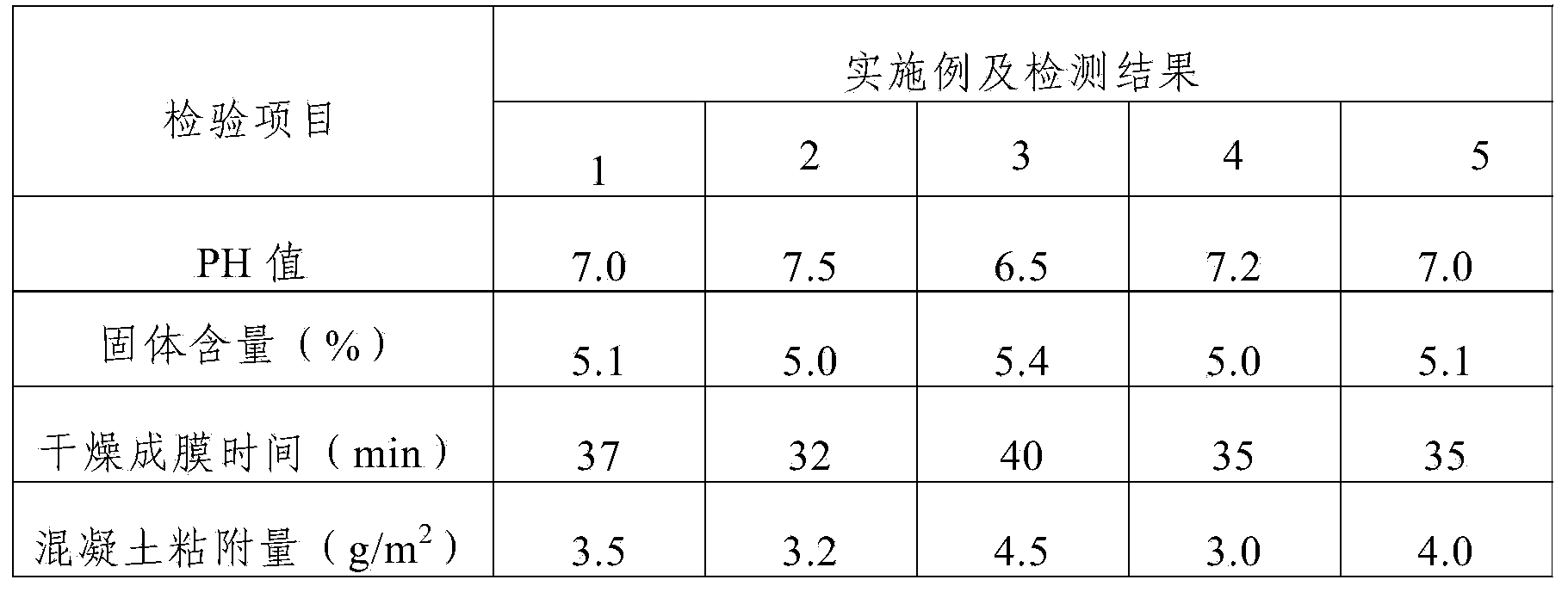

Embodiment 1

[0018] The environmentally friendly oil-based emulsification release agent of this embodiment is made from the following raw materials by mass percentage: waste oil 30%, mineral oil 20%, polyoxyethylene ether 0.5%, triethanolamine 0.05%, water-based silane coupling agent (KH- 550) 0.2%, the balance is deionized water.

[0019] The preparation method of the environmentally friendly oil-based emulsification release agent in this embodiment is as follows: dissolve 200 g of water-based silane coupling agent (KH-550) in 3800 mL of deionized water to prepare a silane coupling agent solution with a mass concentration of 5%, and then mix 30 kg of Waste engine oil, 20kg of mineral oil, 500g of polyoxyethylene ether, 50g of triethanolamine and the prepared silane coupling agent solution were added to the reaction kettle in turn, and the reaction was stirred at 70 ° C for 30min, and then 45.45kg of deionized water was added to the reaction kettle, The stirring reaction was continued for ...

Embodiment 2

[0021] The environmentally friendly oil-based emulsification release agent of this embodiment is made from the following raw materials by mass percentage: 40% of waste oil, 20% of mineral oil, 0.5% of polyoxyethylene ether, 0.05% of triethanolamine, water-based silane coupling agent (KH- 560) 0.2%, the balance is deionized water.

[0022] The preparation method of the environmentally friendly oil-based emulsification release agent in this embodiment is as follows: pour 200 g of water-based silane coupling agent (KH-560) into 3800 mL of deionized water to prepare a silane coupling agent solution with a mass concentration of 5%, and then add 40 kg of water-based silane coupling agent (KH-560). Waste oil, 20kg of mineral oil, 500g of polyoxyethylene ether, 50g of triethanolamine and the prepared silane coupling agent solution were added to the reactor successively, and the reaction was stirred at 80°C for 20min, then 35.45kg of deionized water was added to the reactor, The stirri...

Embodiment 3

[0024] The environmentally friendly oil-based emulsification release agent of this embodiment is made of the following raw materials by mass percentage: mineral oil 50%, polyoxyethylene ether 0.5%, triethanolamine 0.05%, water-based silane coupling agent (KH-570) 0.2%, The balance is deionized water.

[0025] The preparation method of the environmentally friendly oil-based emulsification release agent in this embodiment is as follows: pour 200 g of water-based silane coupling agent (KH-570) into 3800 mL of deionized water to prepare a silane coupling agent solution with a mass concentration of 5%, and then mix 50 kg of water-based silane coupling agent (KH-570). Mineral oil, 500g of polyoxyethylene ether, 50g of triethanolamine and the prepared silane coupling agent solution were added to the reaction kettle in turn, and the reaction was stirred at 60°C for 40min. Then 45.45kg of deionized water was added to the reaction kettle, and the reaction was continued for 40min. , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com