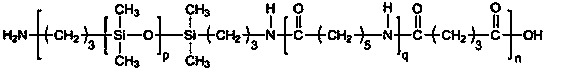

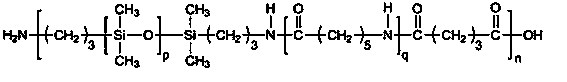

Polyamide organic silicon thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and polyamide-based technology, which is applied in the field of polyamide-based silicone thermoplastic elastomer and its preparation, can solve the problems of macroscopic phase separation, poor compatibility between silicone and polyamide, and narrow operating window range. The effect of wide operating window, orderly chain structure, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100g of octamethylcyclotetrasiloxane, introduce a nitrogen stream to drive off the air and moisture in the system, and add 0.1g of catalyst in turn Tetramethylammonium hydroxide and 5.2g end-capping agent bisaminopropyltetramethyldisiloxane were stirred and reacted at 90°C for 6 hours under nitrogen protection;

[0026] 2) Subsequently, the temperature was raised to 150°C, the catalyst was decomposed and destroyed for 1 hour, and then devolatilized at 135°C and 0.07KPa for 1 hour to obtain an aminopropyl-terminated polydimethylsiloxane with an average molar mass of 5000 g / mol;

[0027] 3) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100g of caprolactam, introduce a stream of nitrogen to drive off the air and moisture in the system, and add 3g catalyst 6-aminocaproic acid, 3.1g The end-capping agent, adipic acid, was stirred at 150 °C for 0.5 hours un...

Embodiment 2

[0032] 1) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100g of octamethylcyclotetrasiloxane, introduce a nitrogen stream to drive off the air and moisture in the system, and add 0.1g of catalyst in turn Tetramethylammonium hydroxide, 7.7g end-capping agent bisaminopropyltetramethyldisiloxane;

[0033] 2) The reaction was stirred at 100 °C for 6 hours under nitrogen protection, then heated to 150 °C, decomposed and destroyed the catalyst for 1 hour, and then devolatilized at 135 °C and 0.07KPa for 1 hour to obtain an average molar mass of 3500g / mol. base polydimethylsiloxane;

[0034] 3) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100g of caprolactam, introduce a nitrogen stream to drive out the air and moisture in the system, and add 3g of catalyst 6-aminocaproic acid, 4.5g of The end-capping agent, adipic acid, was stirred at 160 °C for 0.5 hours under nitrogen protection, then heated to 250 °C and co...

Embodiment 3

[0039] 1) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100g of octamethylcyclotetrasiloxane, introduce a nitrogen stream to drive out the air and moisture in the system, and add 0.1g of catalyst tetramethyl ammonium hydroxide, 14.0 g of end-capping agent bisaminopropyltetramethyldisiloxane, and stirred for 6 hours at 100°C under nitrogen protection;

[0040] 2) Subsequently, the temperature was raised to 150°C, the catalyst was decomposed and destroyed for 1 hour, and then devolatilized at 135°C and 0.07KPa for 1 hour to obtain an aminopropyl-terminated polydimethylsiloxane with an average molar mass of 2000 g / mol;

[0041] 3) In a reactor equipped with a stirrer, a reflux condenser and a nitrogen pipe, add 100 g of caprolactam, introduce a nitrogen stream to drive out the air and moisture in the system, and add 3 g of the catalyst 6-aminocaproic acid, 8.6 g of The end-capping agent, adipic acid, was stirred at 160 °C for 0.5 hours under n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com