Sorbitol modified aromatic polyester polyol for hard foam and preparation method thereof

A technology of aromatic polyester and sorbitol, which is applied in the field of sorbitol-modified aromatic polyester polyol for hard foam and its preparation, can solve the problems of increased processing costs, easy shrinkage of products, and low functionality, and achieves Reduced consumption, low production cost, and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

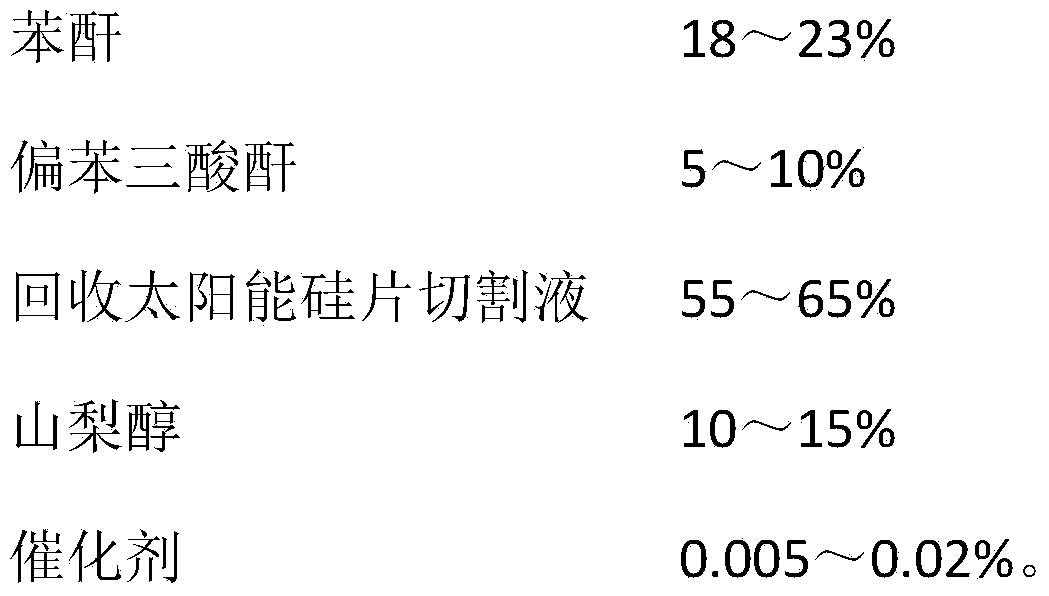

[0022] Sorbitol-modified aromatic polyester polyol for rigid foam, including the following components:

[0023]

[0024] The preparation method of the sorbitol-modified aromatic polyester polyol for hard foam is as follows: put the low-molecular polyol raw material, phthalic anhydride, trimellitic anhydride and catalyst into the polyester reaction kettle; 2 Protection, use high temperature and high pressure steam heating method, slowly increase the temperature to 225°C, and control the gas phase temperature below 98°C; when the water output reaches 85% of the theoretical water output, keep it warm for 1h; turn off the nitrogen, start vacuuming, and the vacuum degree ≤0.095MPa, keep the temperature at 217-223°C, stop the reaction when the acid value of the product is ≤2mg KOH / g, and the functionality is ≥3.1; cool down to below 80°C and press filter to get viscous transparent yellow-brown Aromatic polyester polyol (hydroxyl value 380mg KOH / g, acid value 1.7mg KOH / g, moisture...

Embodiment 2

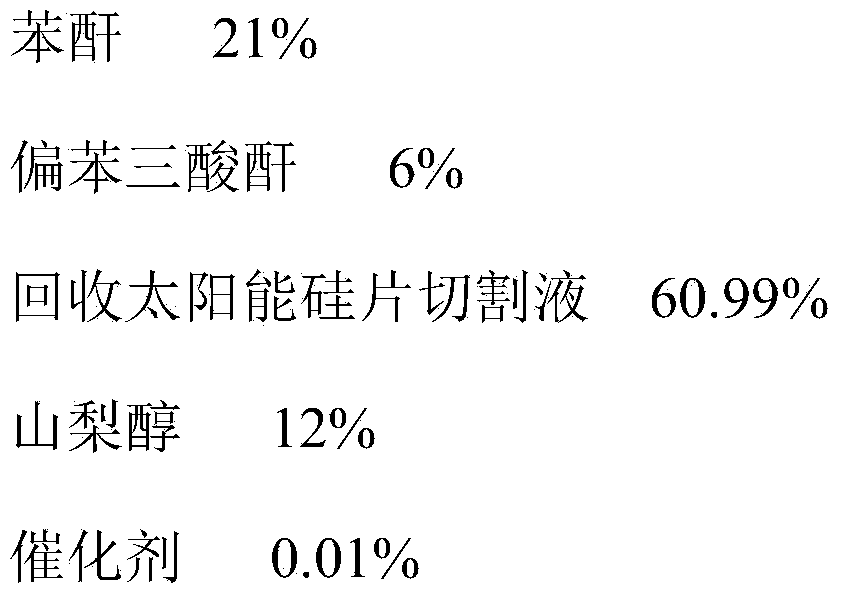

[0026] Sorbitol-modified aromatic polyester polyol for rigid foam, including the following components:

[0027]

[0028]

[0029] Put low-molecular polyol raw materials, phthalic anhydride, trimellitic anhydride and catalysts into the polyester reactor; 2 Protection, use high temperature and high pressure steam heating method, slowly increase the temperature to 225°C, and control the gas phase temperature below 98°C; when the water output reaches 85% of the theoretical water output, keep it warm for 1h; turn off the nitrogen, start vacuuming, and the vacuum degree ≤0.095MPa, keep the temperature at 217~223°C, stop the reaction when the acid value of the product is ≤2mgKOH / g, and the functionality is ≥3.1; cool to below 80°C and filter the material to obtain a viscous transparent yellow-brown aroma Family polyester polyol (hydroxyl value 391mg KOH / g, acid value 1.9mg KOH / g, moisture 0.03%).

Embodiment 3

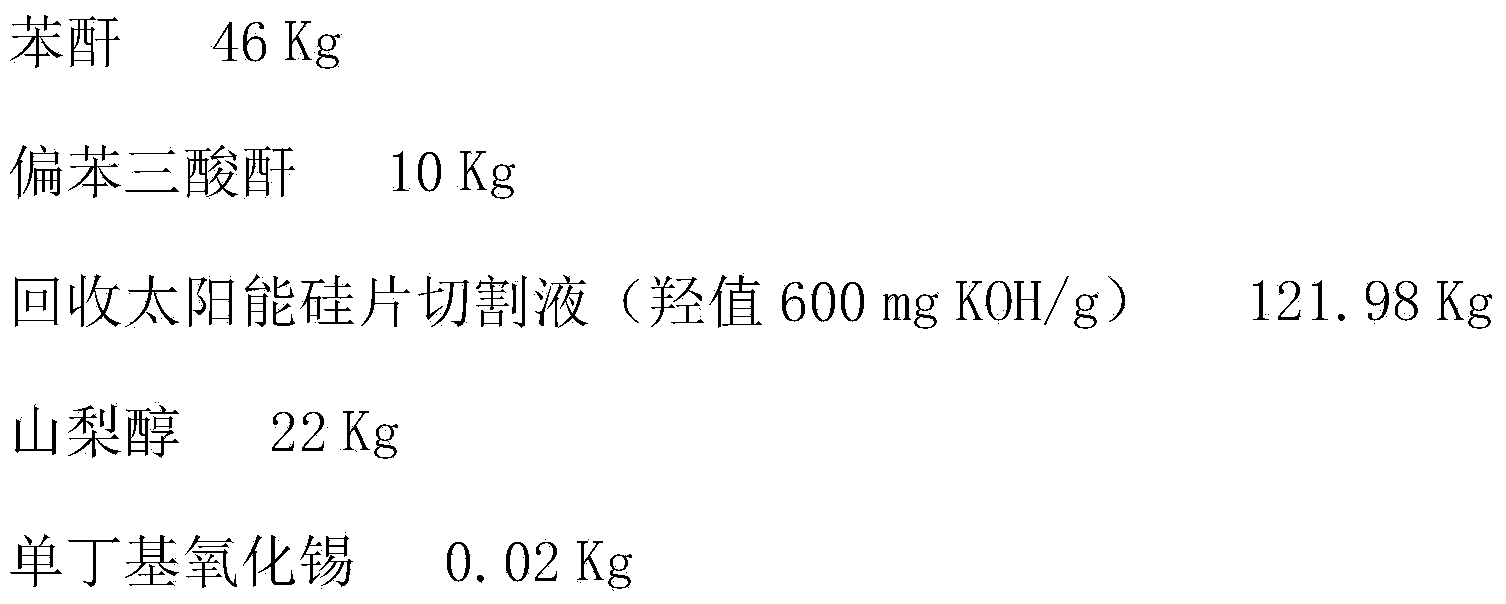

[0031] Sorbitol-modified aromatic polyester polyol for rigid foam, including the following components:

[0032]

[0033] Put low-molecular polyol raw materials, phthalic anhydride, trimellitic anhydride and catalysts into the polyester reactor; 2 Protection, use high temperature and high pressure steam heating method, slowly increase the temperature to 225°C, and control the gas phase temperature below 98°C; when the water output reaches 85% of the theoretical water output, keep it warm for 1h; turn off the nitrogen, start vacuuming, and the vacuum degree ≤0.095MPa, keep the temperature at 217~223°C, stop the reaction when the acid value of the product is ≤2mgKOH / g, and the functionality is ≥3.1; cool to below 80°C and filter the material to obtain a viscous transparent yellow-brown aroma Family polyester polyol (hydroxyl value 445mg KOH / g, acid value 1.8mg KOH / g, moisture 0.03%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com