A kind of preparation method of crosslinking agent and crosslinking controllable high temperature resistant gel

A technology of cross-linking agent and trimethylol phenol, which is applied in the field of preparation of cross-linking agent and cross-linking controllable high-temperature resistant gel, which can solve the problems of uncontrollable cross-linking time, weak gel strength, and poor temperature resistance , to achieve control of cross-linking time, good water solubility and good cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

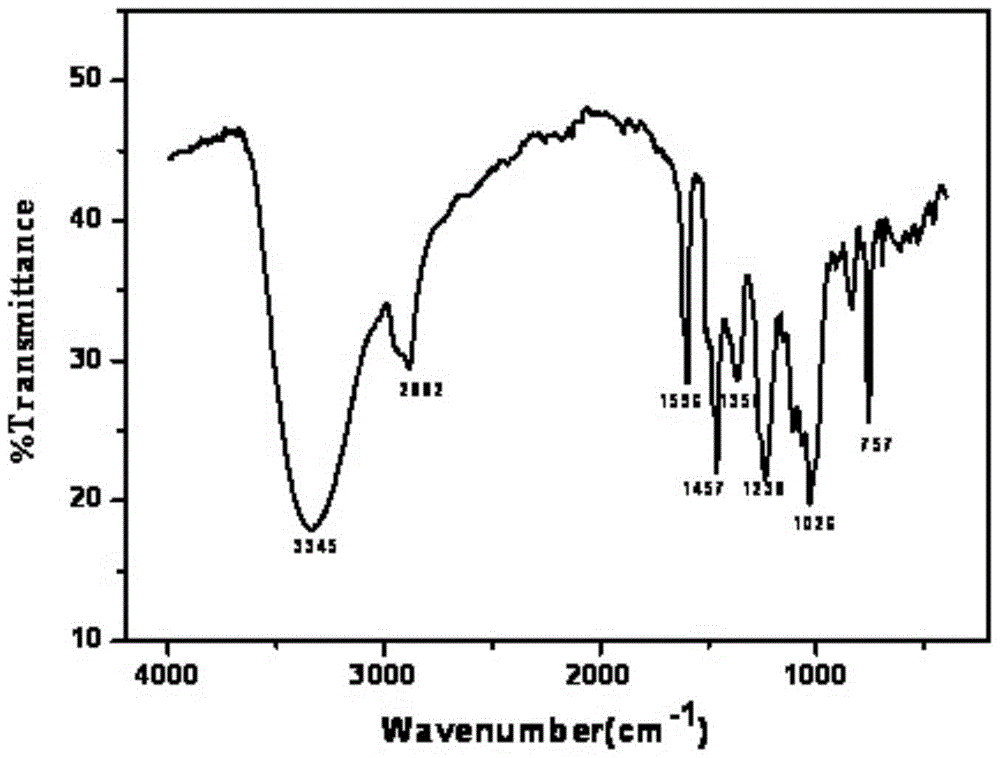

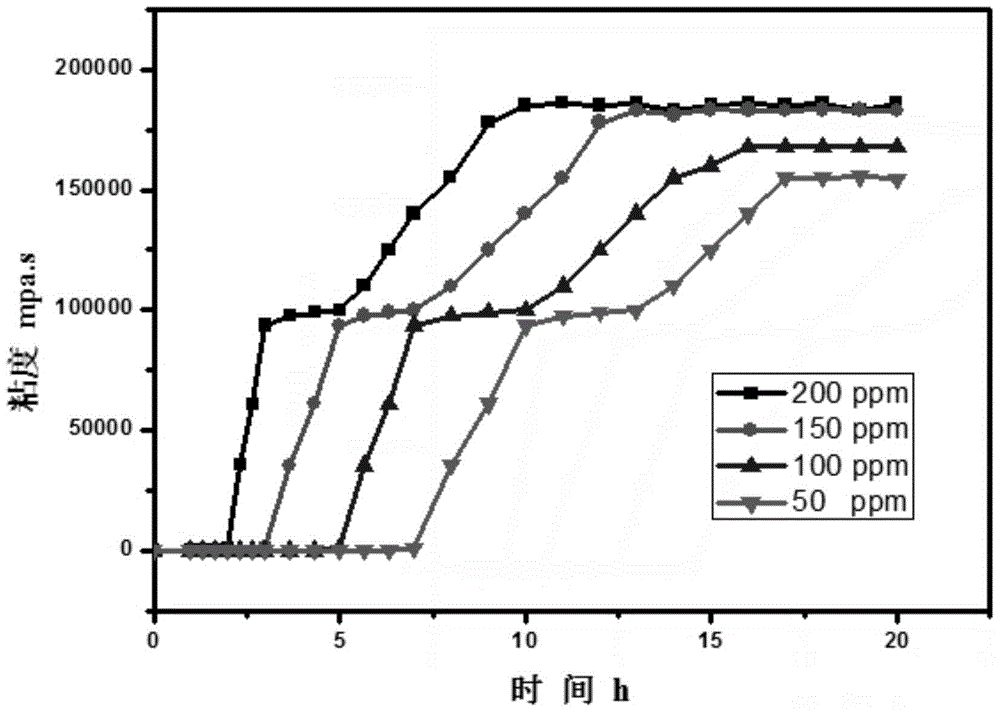

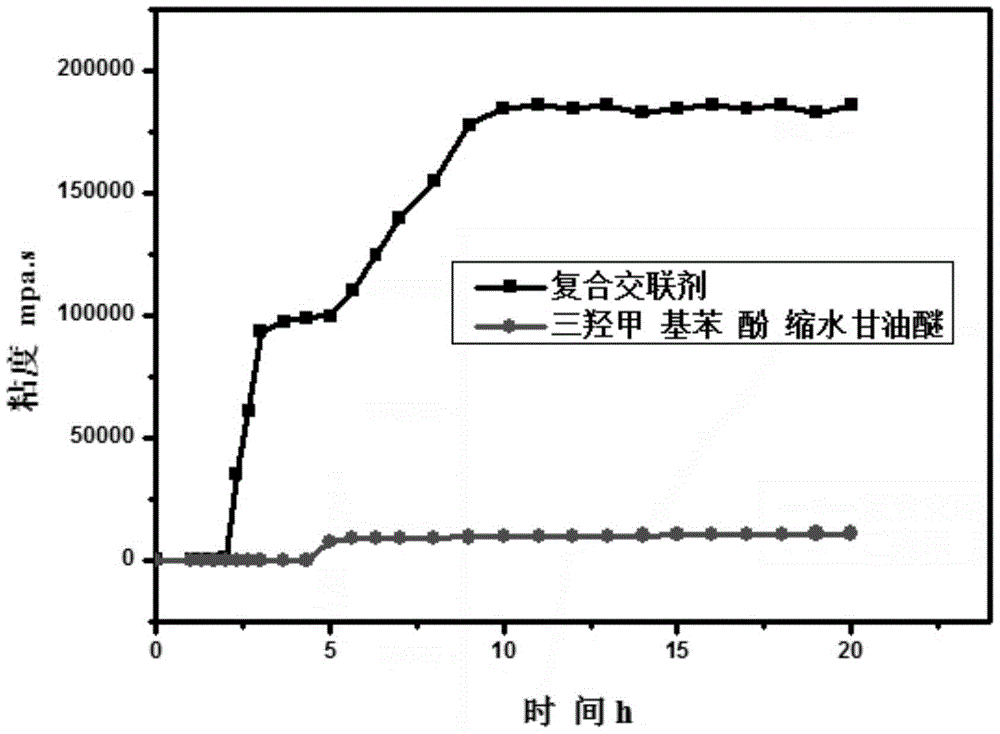

Embodiment 1

[0037] A 250ml three-neck flask equipped with a thermometer and mechanical stirring was placed in a water bath, and the temperature of the water bath was set at 65°C. Add 15.03g (0.16mol) of phenol, 40.02g (0.49mol) of 37% formaldehyde solution, and 0.054g of ethylenediamine into the flask, stir well and raise the temperature to 70°C. The reaction process is observed by TLC, and trimethylol is completely formed For base phenol, add 0.085g cetyltrimethylammonium chloride, 14.82g (0.16mol) epichlorohydrin, slowly add 16g 40% NaOH (0.16mol) aqueous solution dropwise, and raise the temperature to 90°C for 2 hours after the dropwise addition , naturally cooled to obtain 84.09 g of water-soluble, transparent light yellow crosslinking agent. Polyacrylamide (PAM) with a molecular weight of 7 million and a degree of hydrolysis of 25% was prepared with 3.5% saline to a concentration of 0.6wt% and 0.7wt%, and the obtained trimethylolphenol glycidyl ether was added to crosslink agents an...

Embodiment 2

[0042] The molecular weight is 7,000,000, the degree of hydrolysis is the PAM of 25%, is prepared as the concentration of 0.4wt% and 0.5wt% with the brine of mass fraction 3.5%, adds the obtained trimethylolphenol glycidyl ether cross-linking agent and cross-linking agent of example 1 joint accelerator. The degree of gel crosslinking was characterized by gel viscosity and GelStrengthCodes method. The viscometer is: NDJ-1B rotational viscometer, 4# rotor 6rpm, the measurement is at room temperature, and the maximum temperature resistance temperature is the highest temperature at which the gel does not appear water separation after 24h high temperature treatment.

[0043] Table 2

[0044]

[0045] It can be seen from Table 2 that when the PAM concentration is 0.4wt% and 0.5wt%, the gel strength after crosslinking can reach the low deformation and non-flowing glue H grade and the rigid glue I grade, and the temperature resistance temperature can be above 180°C. This is much ...

Embodiment 3

[0047] The molecular weight is 7,000,000, and the degree of hydrolysis is 25% PAM, is prepared as the concentration of 0.2wt% and 0.3wt% with the brine of mass fraction 3.5%, adds the obtained trimethylolphenol glycidyl ether cross-linking agent and cross-linking agent of example 1 joint accelerator. The degree of gel crosslinking was characterized by gel viscosity and GelStrengthCodes method. The viscometer is: NDJ-1B rotational viscometer, 4# rotor 6rpm, the measurement is at room temperature, and the maximum temperature resistance temperature is the highest temperature at which the gel does not appear water separation after 24h high temperature treatment.

[0048] table 3

[0049]

[0050] It can be seen from Table 3 that when the concentration of PAM is reduced to 0.2wt% and 0.3wt%, the gel strength after crosslinking can reach grade G of non-flowing medium-deformation glue and grade H of low-deformation glue, which have good strength and temperature resistance The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com