Chicory fermented soybean milk and making method thereof

A technology of fermenting soybean milk and chicory, which is applied in the direction of dairy products, milk preparations, applications, etc., to achieve the effect of high nutritional value, smooth and delicate entrance, and complete flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

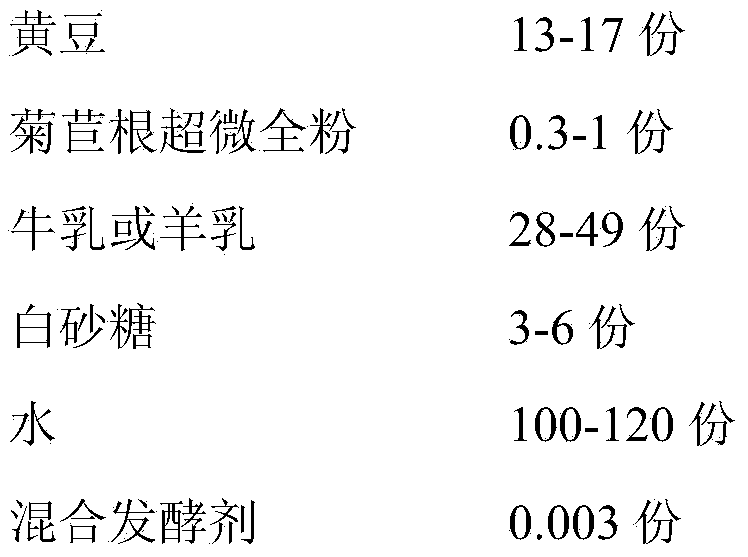

[0021] 1 recipe (both by mass)

[0022]

[0023] 2 process points

[0024] 2.1 Wash and slice the chicory root, dry it at 65°C until the moisture content is less than 6%, cool to room temperature, and ultrafinely pulverize it to obtain the original chicory root superfine powder; dry the chicory root slice at 65°C and roast at 85°C After 12 hours, cool to room temperature, and perform ultrafine pulverization to obtain ultrafine whole powder of coffee-flavored chicory root.

[0025] 2.2 Wash the soybeans and soak them overnight in a sodium bicarbonate solution with a concentration of 0.5% (m / v).

[0026] 2.3 Take the ultrafine whole chicory root powder and the washed soybeans, add water to boil and grind while hot. After the beating is completed, filter the bean dregs with a filter cloth.

[0027] 2.4 Add fresh milk and white sugar to prepare, stir evenly, boil and sterilize for 10 minutes.

[0028] 2.5 After the soybean milk is cooled, inoculate the mixed starter under a...

Embodiment 2

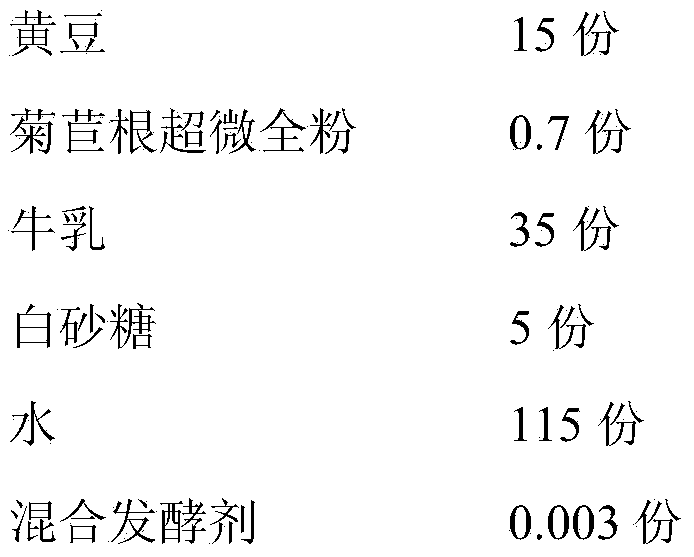

[0032] 1 recipe (both by mass)

[0033]

[0034]

[0035] 2 process points

[0036] 2.1 Wash and slice the chicory root, dry at 65°C until the moisture content is lower than 6%, and perform ultrafine grinding to obtain the original chicory root ultrafine powder.

[0037] 2.2 Wash the soybeans and soak them overnight in a sodium bicarbonate solution with a concentration of 0.5% (m / v).

[0038] 2.3 Take the ultrafine whole chicory root powder and the washed soybeans, add water to boil and grind while hot. After the beating is completed, filter the bean dregs with a filter cloth.

[0039] 2.4 Add fresh milk and white sugar to prepare, stir evenly, boil and sterilize for 10 minutes.

[0040] 2.5 After the soybean milk is cooled, inoculate mixed starters of different compositions under aseptic conditions. The mixed starters are composed of: Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium, Lactobacillus acidophilus, and Lactobacillus casei. 4:2:1:1:1 ...

Embodiment 3

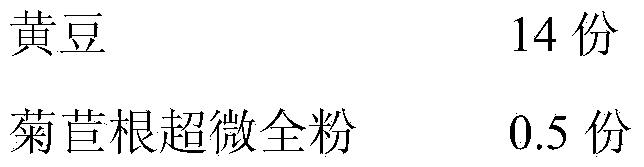

[0044] 1 recipe (both by mass)

[0045]

[0046] 2 process points

[0047] 2.1 Wash and slice the chicory root, dry at 65°C until the moisture content is lower than 6%, and perform ultrafine grinding to obtain the original chicory root ultrafine powder.

[0048] 2.2 Wash the soybeans and soak them overnight in a sodium bicarbonate solution with a concentration of 0.5% (m / v).

[0049] 2.3 Take the ultrafine whole chicory root powder and the washed soybeans, add water to boil and grind while hot. After the beating is completed, filter the bean dregs with a filter cloth.

[0050] 2.4 Add fresh goat's milk and white sugar for preparation, stir evenly and boil for 10 minutes to sterilize.

[0051]2.5 After the soybean milk is cooled, inoculate the mixed starter under aseptic conditions (the ratio of Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium, Lactobacillus acidophilus, and Lactobacillus casei is 2:2:1:1:1) , Stir evenly, pack into containers and fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com