Method for preparing beverage containing milk minerals

A milk mineral salt and beverage technology, applied in dairy products, food science, milk preparations, etc., can solve problems such as poor beverage organization, poor beverage taste experience, and poor taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The preparation of embodiment 1 milk mineral salt drink A

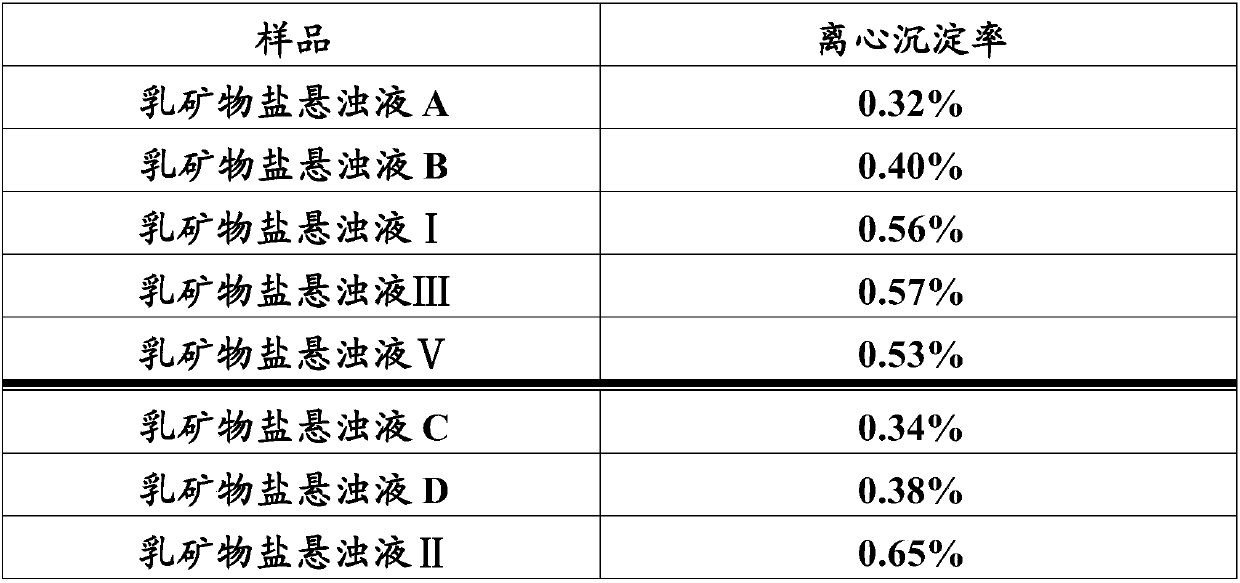

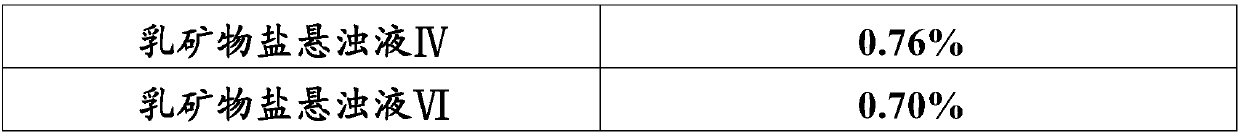

[0087] Mix milk mineral salt i, gum arabic, and purified water at a weight ratio of 5:1:19 at 20°C to 30°C to obtain a mixed material; use a ball mill to grind the mixed material at a speed of 2500rpm, during the grinding process, through the circulation The cooling system keeps the temperature of the mixed material at 25°C, and the solid particles are taken every 15 minutes to measure the particle size until the particle size D90 of the solid particles reaches 2.5 microns and the grinding is stopped for a total of 90 minutes. Mix the ground material with purified water at a weight ratio of 1:99 to obtain milk mineral salt suspension A. Add 0.03% (W / W) sodium hexametaphosphate to milk mineral salt suspension A and continue mixing, then add 2% (W / W) ~ 5% (W / W) sucrose and 0.01% (W / W) ~0.05% (W / W) flavoring, after homogenization treatment and UHT ultra-high temperature sterilization, aseptic canning, to obtain ...

Embodiment 2

[0088] The preparation of embodiment 2 milk mineral salt beverage B

[0089] Mix milk mineral salt i, soluble soybean polysaccharide and purified water at a weight ratio of 2:1:7 at 20°C to 30°C to obtain a mixed material; use a ball mill to grind the mixed material at a speed of 2500rpm. During the grinding process, pass The circulating cooling system keeps the temperature of the mixed material at 25°C, and the solid particles are taken every 15 minutes to measure the particle size until the particle size D90 of the solid particles reaches 2.5 microns and the grinding is stopped for a total of 90 minutes. Mix the ground material with purified water at a weight ratio of 1:99 to obtain milk mineral salt suspension B. Add 0.03% (W / W) sodium hexametaphosphate to milk mineral salt suspension B and continue mixing, then add 2% (W / W) ~ 5% (W / W) sucrose and 0.01% (W / W) ~0.05% (W / W) flavoring, after homogenization treatment and UHT ultra-high temperature sterilization, aseptic cann...

Embodiment 3

[0090] The preparation of embodiment 3 high calcium milk C

[0091]Mix milk mineral salt ii, gum arabic, and purified water at a weight ratio of 5:1:19 at 20°C to 30°C to obtain a mixed material; use a ball mill to grind the mixed material at a speed of 2500rpm. The cooling system keeps the temperature of the mixture at 25°C, and the solid particles are taken every 15 minutes to measure the particle size until the particle size D90 of the solid particles reaches 2.5 microns and the grinding is stopped for a total of 90 minutes; the ground material and milk are mixed according to the ratio of 1:300 Mix by weight ratio to obtain milk mineral salt suspension C; add 0.03% (W / W) sodium hexametaphosphate to milk mineral salt suspension C to continue mixing, and then undergo homogenization treatment, UHT ultra-high temperature sterilization, no Bacteria filling to obtain high calcium milk C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com