Controllable and high-precision experimental device for researching grinding mechanism

A grinding mechanism and experimental device technology, applied in the direction of testing wear resistance, etc., can solve the problems of small abrasive particles and cannot be installed close to it, and achieve the effects of strong practicability, convenient operation, and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the detailed implementation and specific operation process are given below, but the protection scope of the present invention is not limited to the following embodiments. The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

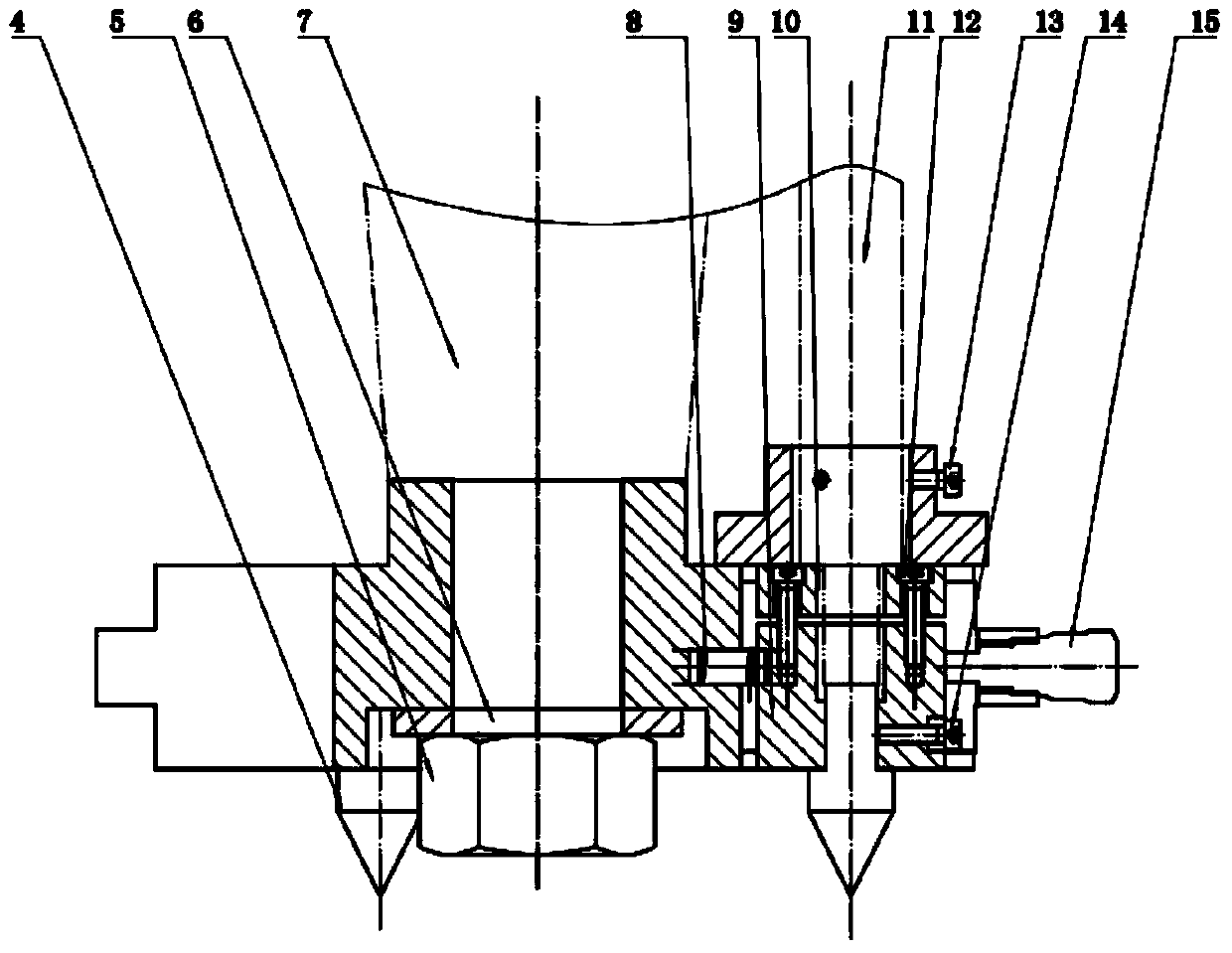

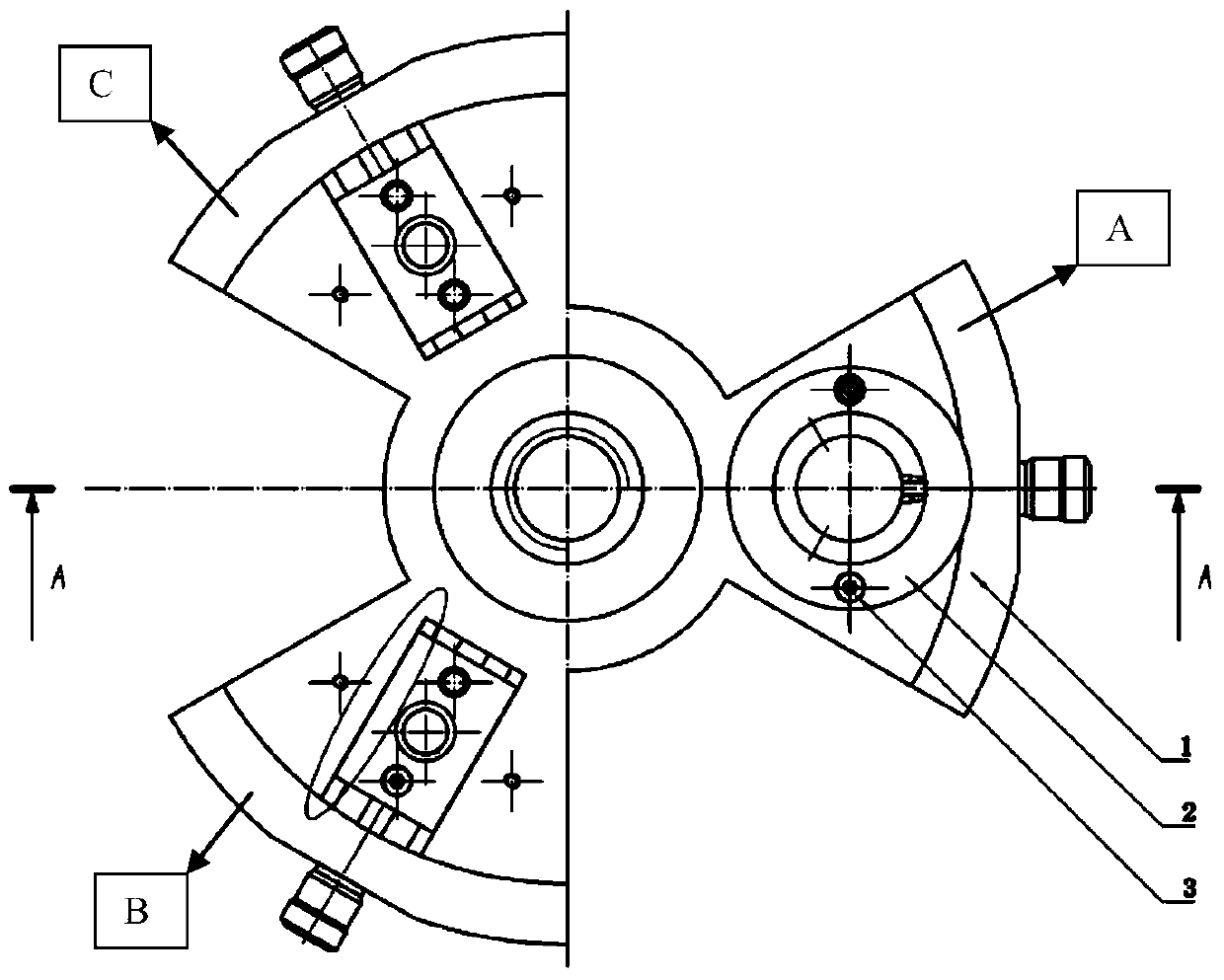

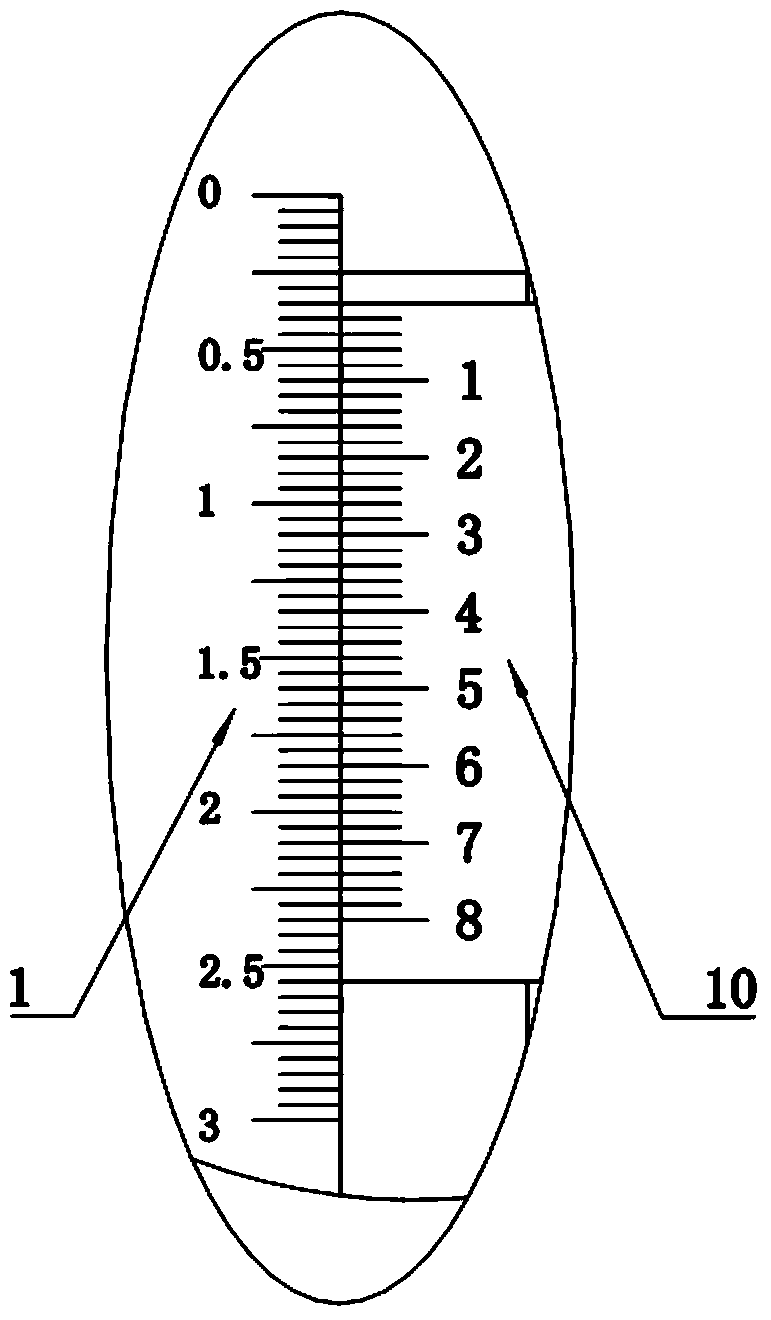

[0026] Such as figure 1 and figure 2 As shown: this embodiment includes: a base body 1, an upper T-shaped slider 10, a lower T-shaped slider 9, a diamond tool 4, an axial spiral micrometer 11, a radial spiral micrometer 15, and a circular clamp 2. For the convenience of description, the sequence labels are defined for the same structures or components with a mutual difference of 120° on the device: figure 2 As shown, def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com