Near-bit torsion impactor

An impactor and near-drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of PDC bit rock breaking process instability, PDC bit damage, and reduced bit life, so as to eliminate stick-slip phenomenon and reduce Drilling cost and the effect of fewer vulnerable parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

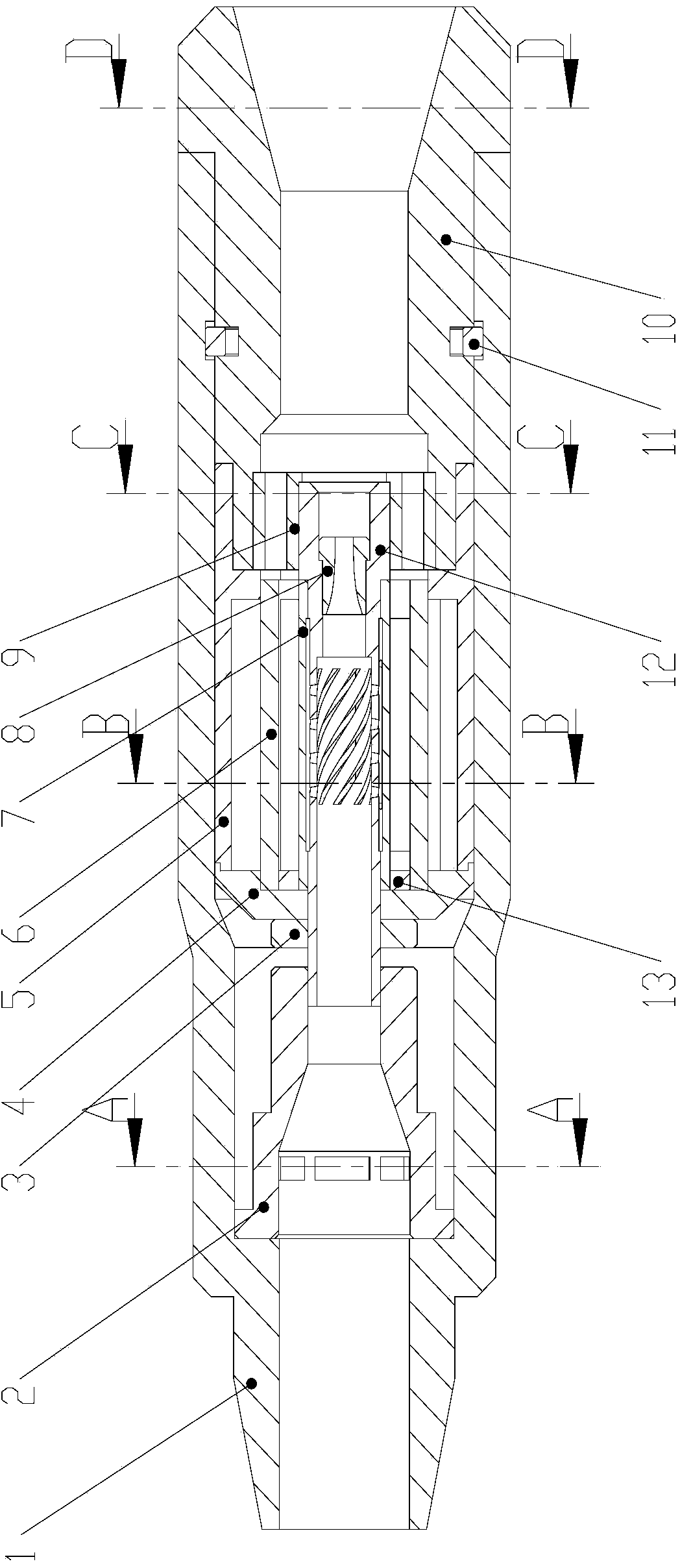

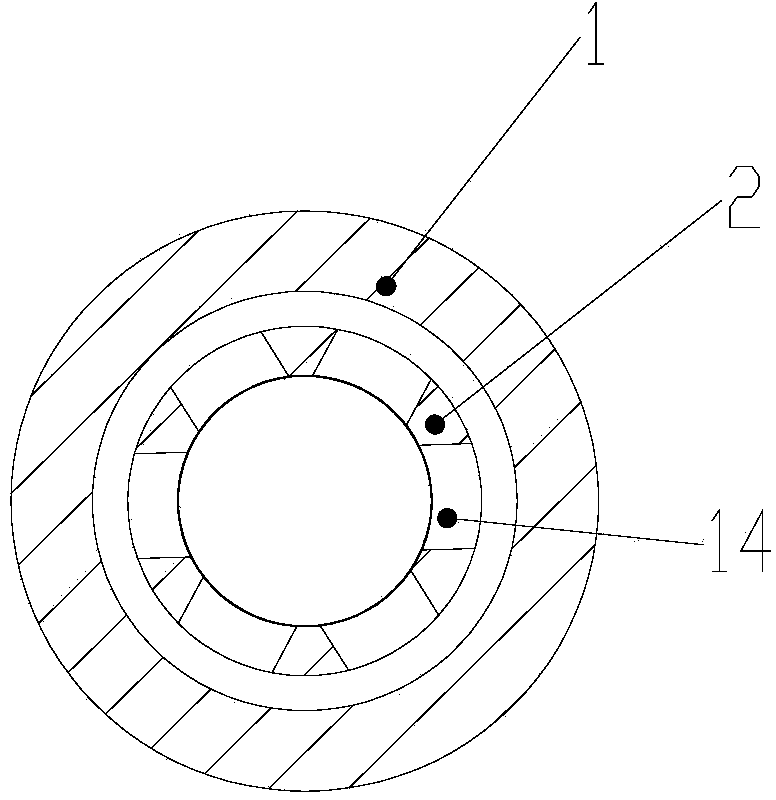

[0026] Such as figure 1 As shown, the torsional impactor near the drill bit of the present invention includes a drill collar short 1, a flow divider 2, a torsional impactor, and an impact transmission short 10. The upper end of the drill collar short 1 is connected to the upper drill collar female through the API standard thread. Buckle end connection, the lower end of the drill collar short 1 is connected with the snap ring 11 and the impact transmission short 10, and the shunt 2, torsional impactor, and the drill collar short are installed between the drill collar short 1 and the impact transmission short 10 1 outside, shunt 2, torsional impactor inside.

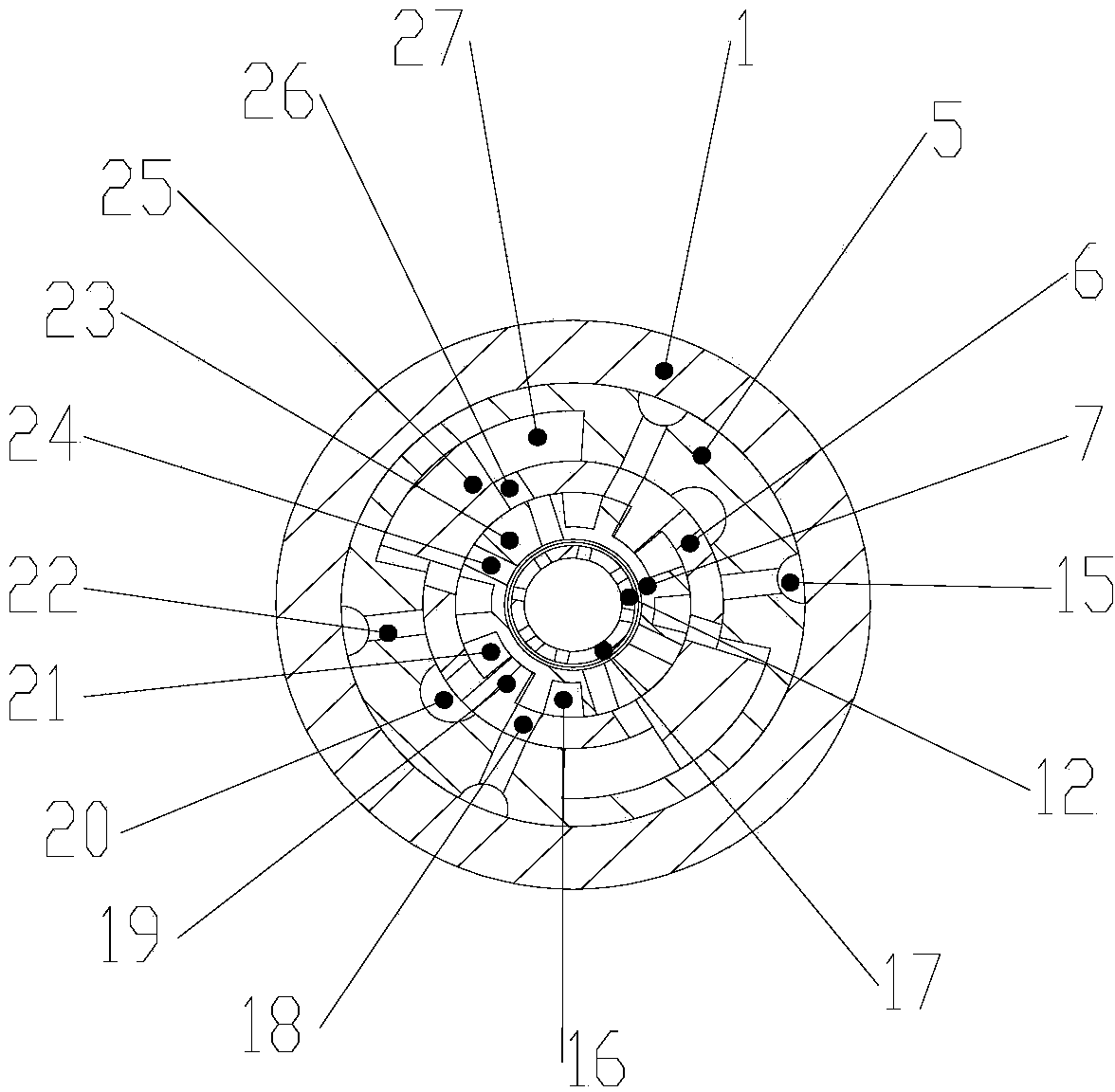

[0027] The torsional impactor is a multi-cavity structure composed of a threaded pressure plate 3, an upper cover body 4, an impactor shell 5, a hydraulic hammer 6, a commutator 7, a throttle no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com