Digital printing dyeing treatment agent, preparation method and application method

A technology of digital printing and application method, which is applied in dyeing method, textile and paper making, etc. It can solve the problems of consuming a lot of heat energy and time, and achieve the effects of short washing time, reduced equipment cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

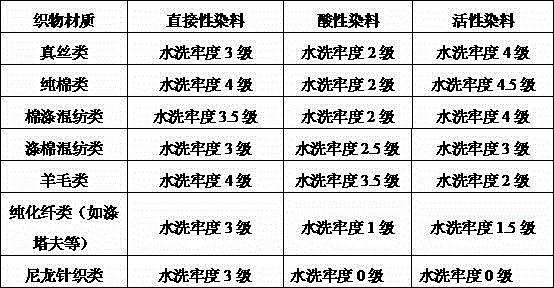

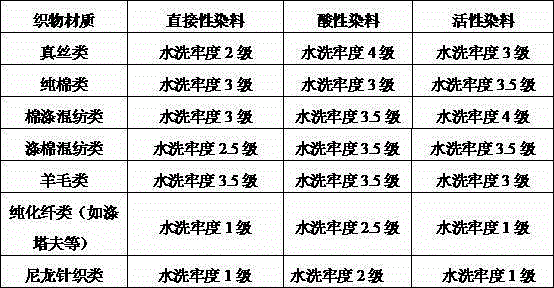

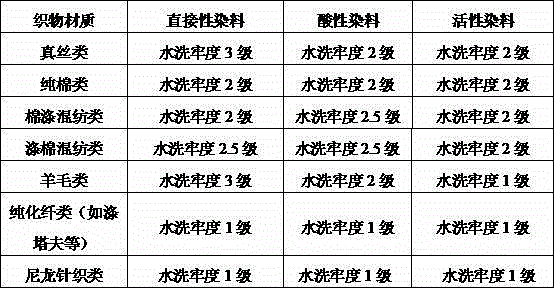

Image

Examples

Embodiment 1

[0079] Embodiment 1: a digital printing dyeing treatment agent, it comprises the following components: (mol / liter)

[0080] 1. Coupling cationic graft modifier

[0081] (1) Dimethyl diallyl ammonium chloride DMDAAC grafting agent 0.6mol / L

[0082] (2) 2,3-epoxypropyltrimethylammonium chloride 0.4mol / L

[0083] (3) Glycerin 0.35mol / L

[0084] (4) Propylene glycol 0.35mol / L

[0085] (5) Ethanol 3mol / L

[0086] (6) Water Make up 1L

[0088] (1) Peracetic acid 2.2mol / L

[0089] (2) Adipic acid 0.2mol / L

[0090] (3) Water Make up 1L

[0091] 3. Chromogen reaction solution

[0092] (1) Deoxygenase-CY-50 0.09mol / L

[0093] (2) Make up 1L of water;

[0094] A kind of preparation method of digital printing dyeing treatment agent, it comprises the following steps:

[0095] (1) Synthesis of coupled cationic graft modifier

[0096] Add dimethyl diallyl ammonium chloride DMDAAC grafting agent, 2,3-epoxypropyl trimethyl ammonium chloride, glycerin a...

Embodiment 2

[0101] Embodiment 2: a kind of digital printing dyeing treatment agent, it comprises following components: (mol / liter)

[0102] 1. Coupling Cationic Grafting Modifier

[0103] (1) Hanbon grafting agent 1.95mol / L

[0104] (2) N-(3-chloro-2-hydroxypropyl) N, N, N trimethylammonium chloride 0.6mol / L

[0105] (3) Humectant G-181.3mol / L

[0106] (4) Ethanol 4mol / L

[0107] (5) Water Make up 1L

[0108] 2. Coupling reagent

[0109] (1) Hydrogen peroxide 2.9mol / L

[0110] (2) Sulfuric acid 0.2mol / L

[0111] (3) Water Make up 1L

[0112] 3. Chromogen reaction solution

[0113] (1) Catalase 0.08mol / L

[0114] (2) Make up 1L of water;

[0115] A kind of preparation method of digital printing dyeing treatment agent, it comprises the following steps:

[0116] (1) Synthesis of coupled cationic graft modifier

[0117] Add Hanbang grafting agent, N-(3-chloro-2-hydroxypropyl) N, N, N trimethyl ammonium chloride and humectant G-18 into water, mix and disperse at 65°C for 2 hours, u...

Embodiment 3

[0122] Embodiment 3: a kind of digital printing dyeing treatment agent, it comprises following components: (mol / liter)

[0123] 1. Coupling Cationic Grafting Modifier

[0124] (1) Modifier-DL8201 3.1mol / L

[0125] (2) 2,3-Epoxypropyltrimethylammonium chloride 1.5mol / L

[0126] (3) Polyethylene glycol PEG-2001.2mol / L

[0127] (4) Isopropanol 4mol / L

[0128] (5) Water Make up 1L

[0129] 2. Coupling reagent

[0130] (1) Sodium Bromate 0.45mol / L

[0131] (2) Water Make up 1L

[0132] 3. Chromogen reaction solution

[0133] (1) Sodium bisulfite 0.25mol / L

[0134] (2) Deoxygenase-CY-500.075mol / L

[0135] (3) Make up 1L of water;

[0136] A kind of preparation method of digital printing dyeing treatment agent, it comprises the following steps:

[0137] (1) Synthesis of coupled cationic graft modifier

[0138] Add modifier-DL8201, 2,3-epoxypropyltrimethylammonium chloride and polyethylene glycol PEG-200 into water, mix and disperse at a constant temperature of 75°C for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com