High-strength wear-resistant anti-corrosion brick and manufacturing method thereof

A high-strength, kaolin technology, applied in the field of refractory materials, can solve the problems of unusable, service life of only one to two months, and service life of only 80 days, etc., to achieve moderate cost, good performance and low wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

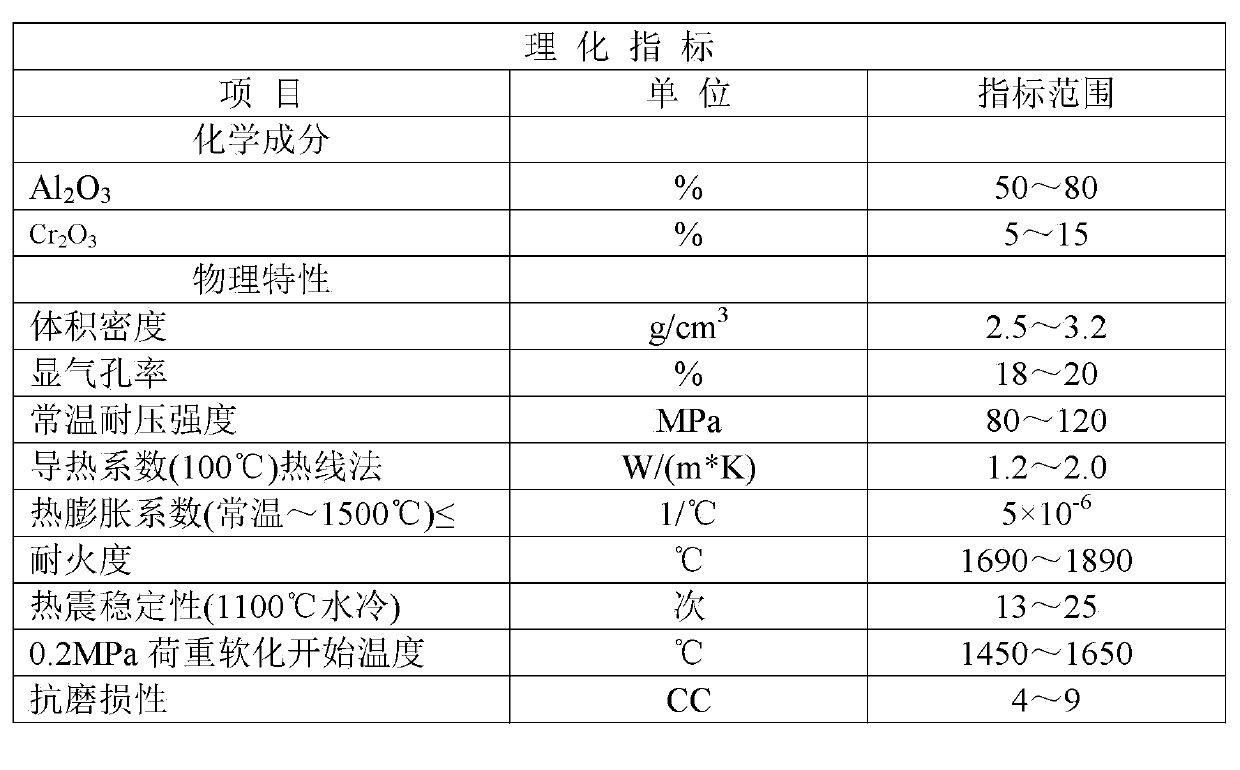

Image

Examples

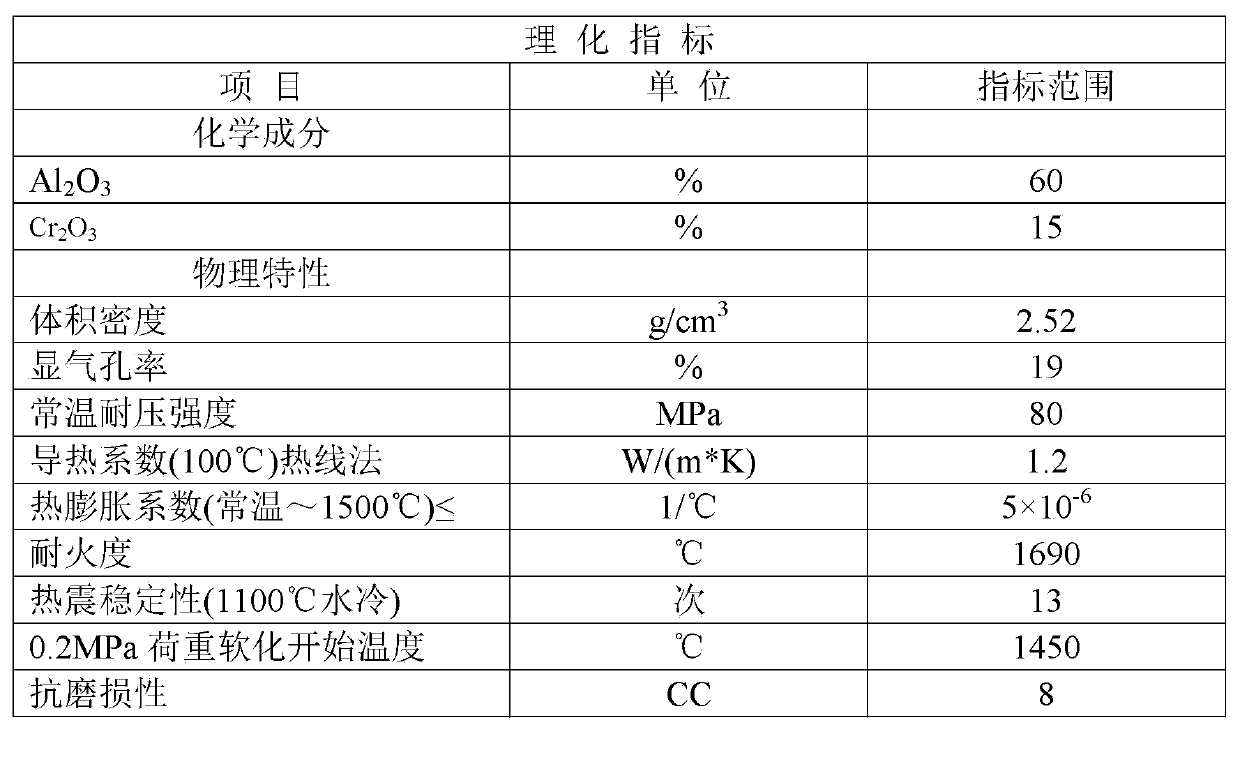

Embodiment 1

[0029] A high-strength, wear-resistant and anti-intrusion brick comprises the following raw materials in parts by weight: 60 parts of bauxite, 20 parts of chrome concentrate, 1 part of metallic silicon micropowder, and 10 parts of kaolin.

[0030] The bauxite contains Al 2 o 3 ≥80%, Fe 2 o 3 ≤1.2%, bulk density 2.6~2.8g / cm 3 , particle size 0-5mm; the chrome concentrate contains Cr 2 o 3 ≥47%, particle size 0-0.05mm; the metal silicon powder contains metal silicon content ≥96, particle size 0-1μm; the kaolin SiO 2 ≥62%, Al 2 o 3 ≥35%, Fe 2 o 3 ≤1.5%, particle size 0~0.05mm.

[0031] A method for preparing high-strength wear-resistant and anti-invasion bricks, comprising the following steps in sequence:

[0032] 1), ingredients: according to the formula, mix bauxite, chrome concentrate, metal silicon micropowder, kaolin, and add 65% phosphoric acid accounting for 2% of the total weight of the above components, send it into the kneader and stir it for 3 minutes, then ...

Embodiment 2

[0040] A high-strength, wear-resistant and anti-intrusion brick comprises the following raw materials in parts by weight: 80 parts of bauxite, 7 parts of chrome concentrate, 10 parts of metal silicon micropowder, and 8 parts of kaolin.

[0041] The bauxite contains Al 2 o 3 ≥85%, Fe 2 o 3 ≤1.2%, bulk density 2.6~2.8g / cm 3 , particle size 0-5mm; the chrome concentrate contains Cr 2 o 3 ≥47%, particle size 0-0.05mm; the metal silicon powder contains metal silicon content ≥96%, particle size 0-1μm; the kaolin SiO 2 ≥62%, Al 2 o 3 ≥35%, Fe 2 o 3 ≤1.5%, particle size 0~0.05mm.

[0042] A method for preparing high-strength wear-resistant and anti-invasion bricks, comprising the following steps in sequence:

[0043] 1), ingredients: according to the formula, mix bauxite, chrome concentrate, metal silicon micropowder, kaolin, and add 30% phosphoric acid accounting for 7% of the total weight of the above components, and send it into the kneader and stir it for 5 minutes befo...

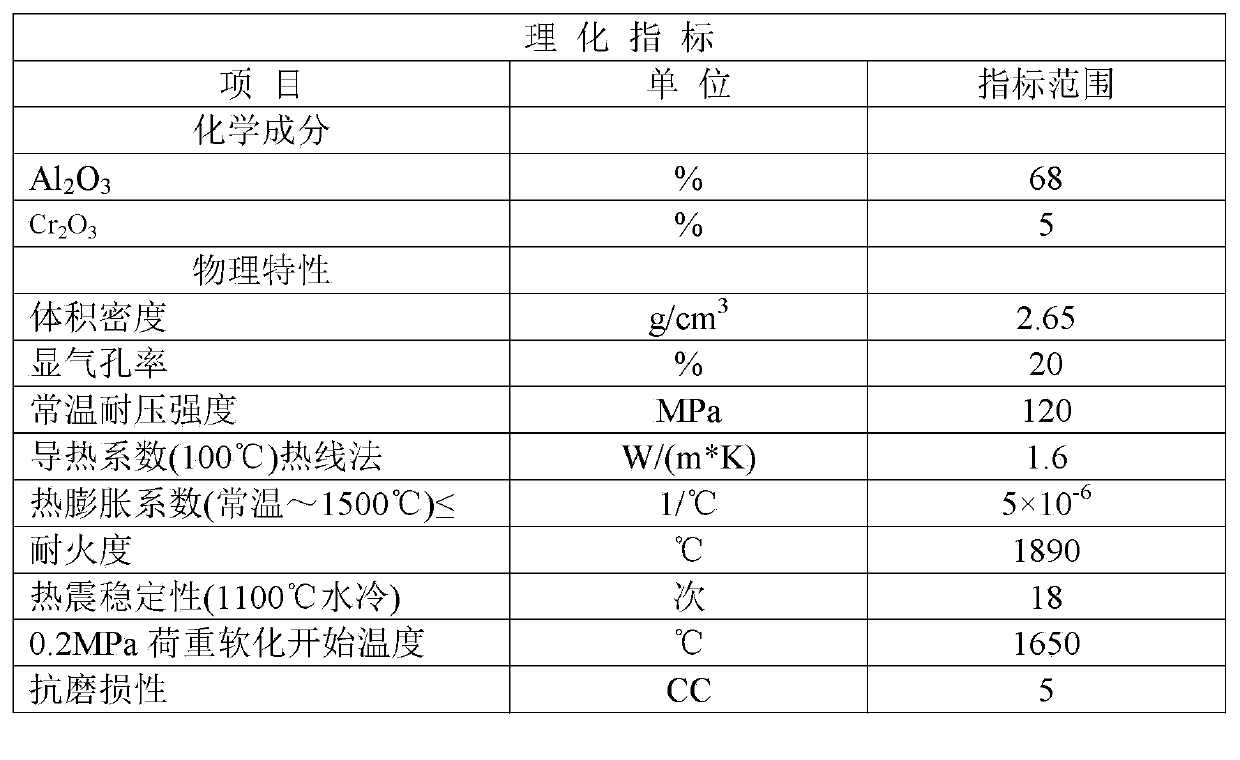

Embodiment 3

[0051] A high-strength, wear-resistant and anti-invasion brick comprises the following raw materials in parts by weight: 75 parts of bauxite, 8 parts of chrome concentrate, 5 parts of metal silicon micropowder, and 1 part of kaolin.

[0052] The bauxite contains Al 2 o 3 ≥85%, Fe 2 o 3 ≤1.2%, bulk density 2.6~2.8g / cm 3 , particle size 0-5mm; the chrome concentrate contains Cr 2 o 3 ≥47%, particle size 0-0.05mm; the metal silicon powder contains metal silicon content ≥96%, particle size 0-1μm; the kaolin SiO 2 ≥62%, Al 2 o 3 ≥35%, Fe 2 o 3 ≤1.5%, particle size 0~0.05mm.

[0053] A method for preparing high-strength wear-resistant and anti-invasion bricks, comprising the following steps in sequence:

[0054] 1), ingredients: according to the formula, mix bauxite, chrome concentrate, metal silicon micropowder, kaolin, add 40% phosphoric acid accounting for 5% of the total weight of the above components, send it into the kneader and stir it for 15 minutes, then take it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com