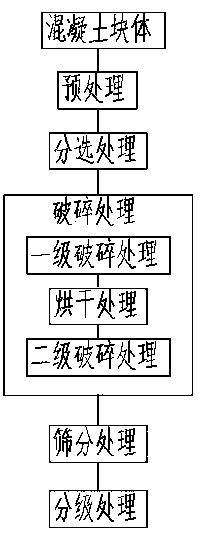

Preparation process of recycled concrete aggregate

A technology for recycled concrete and preparation process, applied in the field of concrete, can solve the problems such as the fact that the production equipment technology of the recycled aggregate preparation process has not been completely solved, the existing process has not been fully considered, and the technical requirements of the equipment are different, so as to achieve convenient operation and improve recycling. rate, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: first hammer the concrete block with a particle size greater than 300mm, cut the steel bars in the concrete block, sort out various impurities in the concrete block, and then remove the waste steel bars in the concrete block with a magnetic device, Afterwards, the concrete block is passed through the separation table to remove non-ferrous impurities, and then the concrete is subjected to primary crushing treatment through the jaw crusher. The model of the jaw crusher is PE-400×600, and the minimum The feed particle size is 300mm, the discharge particle size is set to 45mm, the working frequency of the movable jaw is 75 times / min, the aggregate destruction rate is 25%, the production capacity is 45t / h, and the unit energy consumption is 2400.0kJ / t ; The working frequency of the movable jaw is 100 times / min, the destruction rate of the aggregate is 40%, the production capacity is 63t / h, and the unit energy consumption is 1714.3kJ / t; the working frequency of t...

Embodiment 2

[0021] Embodiment 2: first hammer the concrete block with a particle size greater than 300mm, cut the steel bars in the concrete block, sort out various impurities in the concrete block, and then remove the waste steel bars in the concrete block with a magnetic device, Afterwards, the concrete block is passed through the separation table to remove non-ferrous impurities, and then the concrete is subjected to primary crushing treatment through the jaw crusher. The model of the jaw crusher is PE-400×600, and the minimum The feed particle size is 300mm, the discharge particle size is set to 60mm, the working frequency of the movable jaw is 75 times / min, the aggregate damage rate is 16%, the production capacity is 62t / h, and the unit energy consumption is 1742.0kJ / t ; The working frequency of the movable jaw is 100 times / min, the destruction rate of the aggregate is 15%, the production capacity is 82t / h, and the unit energy consumption is 1317.0kJ / t; the working frequency of the mo...

Embodiment 3

[0023]Embodiment 3: first hammer the concrete blocks with a particle size greater than 300mm, cut the steel bars in the concrete blocks, sort out various impurities in the concrete blocks, and then use magnetic equipment to remove the waste steel bars in the concrete blocks, Afterwards, the concrete block is passed through the separation table to remove non-ferrous impurities, and then the concrete is subjected to primary crushing treatment through the jaw crusher. The model of the jaw crusher is PE-400×600, and the minimum The feed particle size is 300mm, the discharge particle size is set to 70mm, the working frequency of the movable jaw is 75 times / min, the aggregate damage rate is 12%, the production capacity is 50t / h, and the unit energy consumption is 2160.0kJ / t ; The working frequency of the movable jaw is 100 times / min, the destruction rate of the aggregate is 13%, the production capacity is 90t / h, and the unit energy consumption is 1200.0kJ / t; the working frequency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com