Preparation method of graphene

A technology of graphene and graphene solution, applied in the direction of graphene, nanotechnology for materials and surface science, nanocarbon, etc., can solve the problems of high and low specific surface area of graphene, restricting the application of graphene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

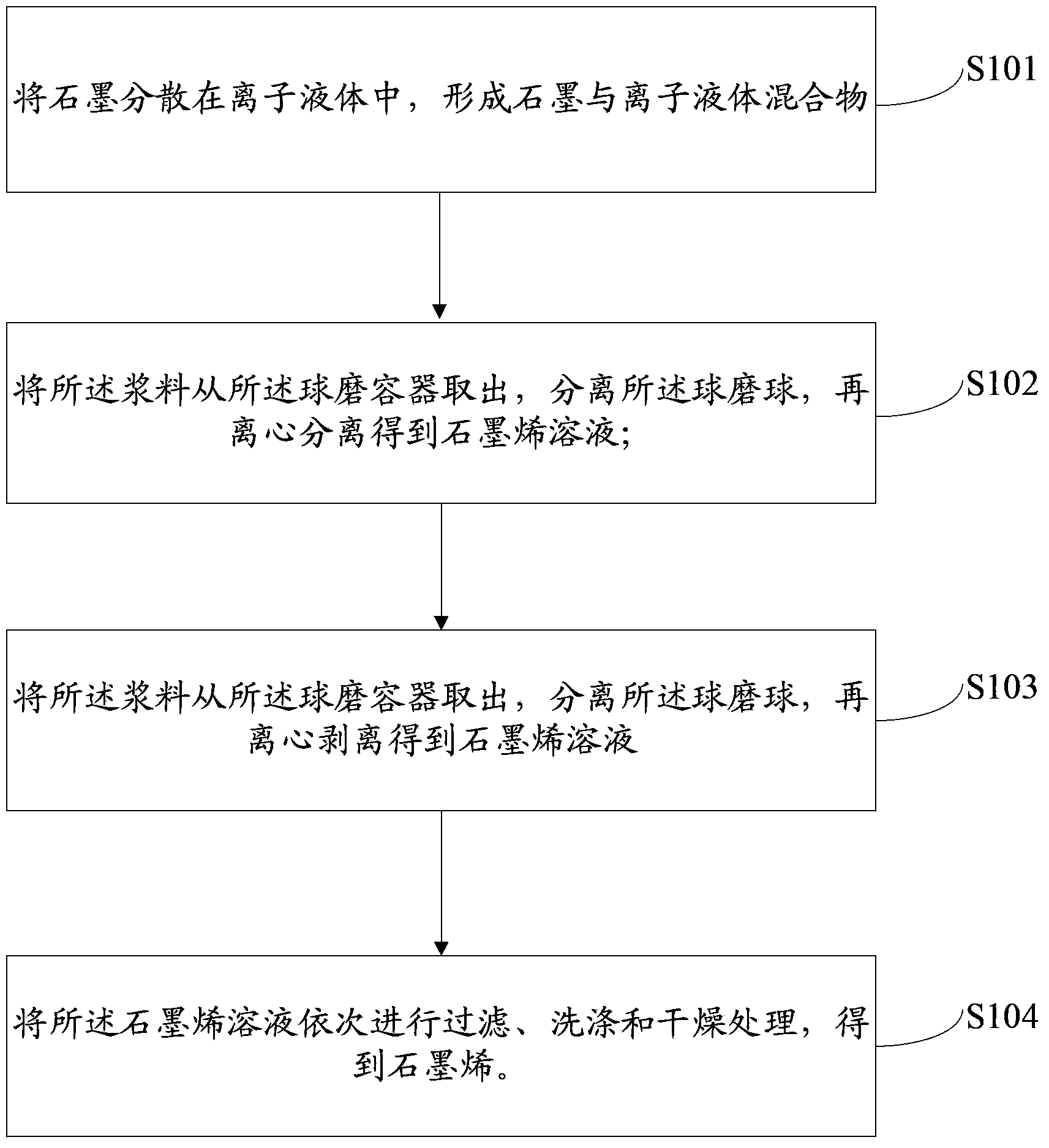

[0023] see figure 1 , the preparation method of the graphene of an embodiment comprises the following steps:

[0024] Step S101, dispersing graphite in ionic liquid to form a mixture of graphite and ionic liquid.

[0025] In this embodiment, graphite is preferably natural flake graphite, artificial graphite, amorphous carbon or expanded graphite. The ionic liquid is preferably 1-ethyl-3-methylimidazolium tetrafluoroboric acid (EtMeImBF 4 ), 1-ethyl-3-methylimidazole trifluoromethanesulfonimide (EtMeImN(CF 3 SO 2 ) 2 ), 1-ethyl-3-methylimidazole trifluoromethanesulfonic acid (EtMeImCF 3 SO 3 ), 1-ethyl-3-methylimidazole trifluoroacetic acid (EtMeImCF 3 CO 2 ), 1-ethyl-3-methylimidazole trifluoromethanesulfonyl carbon (EtMeImC(CF 3 SO 2 ) 3 ), 1-ethyl-3-methylimidazole pentafluoroacetimide (EtMeImN(C 2 f 5 SO 2 ) 2 ), 1-ethyl-3-methylimidazolium dicyanide nitrogen (EtMeImN(CN) 2 ), 1-ethyl-3,5-dimethylimidazolium trifluoromethanesulfonimide (1-Et-3,5-Me 2 ImN(CF...

Embodiment 1

[0036] A kind of preparation method of graphene, its technological process is as follows:

[0037] (1) Prepare 1L of a mixture of natural flake graphite and 1-ethyl-3-methylimidazolium tetrafluoroboric acid with a concentration of 1g / L of natural flake graphite.

[0038] (2) Put the prepared mixture in a 4L stainless steel ball mill container, add balls with a diameter of 5mm, the volume ratio of the added balls to the mixture is 1:2, that is, the volume of the balls is 2L, and then add The lid is sealed. A stainless steel ball milling vessel is installed in the ball milling equipment, the ball milling speed is set at 200 rpm, and the equipment is stopped after 12 hours of ball milling to obtain a slurry.

[0039] (3) Take out the ball milling container, separate the ball milling balls from the solution with a sieve, and centrifuge at a speed of 1000 rpm for 10 minutes with a centrifuge to separate the unexfoliated graphite to obtain a graphene solution.

[0040] (4) Filter th...

Embodiment 2

[0043] A kind of preparation method of graphene, its technological process is as follows:

[0044] (1) Prepare 1L of a mixture of artificial graphite and 1-ethyl-3-methylimidazolium trifluoromethanesulfonimide with an artificial graphite concentration of 10g / L.

[0045] (2) Put the prepared mixture in a 4L stainless steel ball mill container, add balls with a diameter of 10mm, the volume ratio of the added balls to the mixture is 1:1, that is, the volume of the balls is 1L, and then add The lid is sealed. The stainless steel ball milling container is installed in the ball milling equipment, the ball milling speed is set at 400 rpm, and the equipment is stopped after 10 hours of ball milling to obtain the slurry.

[0046] (3) Take out the ball milling container, separate the ball milling balls from the solution with a screen, and centrifuge at a speed of 2000 rpm for 5 minutes to separate the unexfoliated graphite to obtain a graphene solution.

[0047] (4) Filter the graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com