Coupling inductance double tube direct current converter with charge pump

A DC converter and coupled inductor technology, applied in the direction of converting DC power input to DC power output, converting equipment without intermediate conversion to AC, adjusting electrical variables, etc., can solve the problem of diode voltage stress, current stress, and inductor current. Ripple becomes larger and other problems, to achieve the effect of low voltage stress, natural turn-off solution, and low current stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

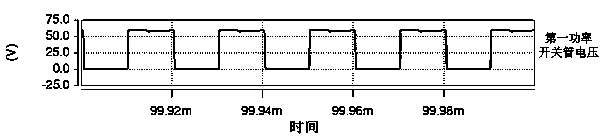

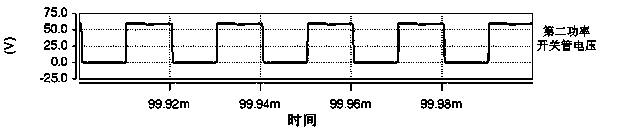

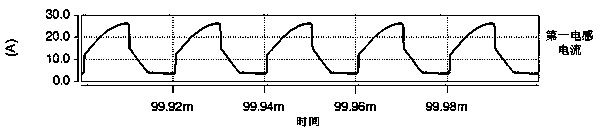

[0030] Such as figure 1 The shown coupled inductance dual-transistor DC converter with a charge pump includes a DC power supply, a first boost circuit, a second boost circuit, a first charge pump boost unit, a second charge pump boost unit, a first Clamping circuit, second clamping circuit, diode and load; the voltage output by the DC power supply is divided into two outputs, one of which is input to the first charge pump boosting unit after being initially boosted by the first boosting circuit, and then input to the first charge pump boosting unit after the first boosting circuit A charge pump boost unit is boosted twice and input to one end of the load through a diode; the first clamping circuit is used to clamp the first boost circuit, and the other circuit is initially boosted by the second boost circuit and then input to The second charge pump boost unit; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com