Device for detecting deposition rate of mortar

A deposition rate and mortar technology, applied in the analysis of materials, instruments, etc., can solve the problems of high relative viscosity of liquids, inconvenient monitoring, etc., and achieve the effects of reducing labor costs, avoiding recording errors, and improving detection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

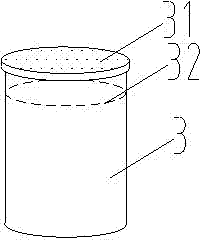

[0029] Such as figure 1 As shown, the present invention provides a device for detecting the rate of mortar deposition, including measuring cylinder 3 ( figure 1 Not shown in), infrared detector 1 and drive device 2; drive device 2 is connected with infrared detector 1, and infrared detector 1 can translate up and down; infrared detector 1 and drive device 2 are connected with central processing unit (in the figure not shown); the central processing unit controls the driving device 2 to drive the infrared detector 1 to move up and down according to the detection result of the infrared detector 1. Infrared detector 1 is in the shape of a "U", and the two arms of the "U" shape are an infrared transmitting end 11 with an infrared transmitter at the end and an infrared receiving end with an infrared receiver at the end, and the infrared transmitter and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com