High-performance chalcogenide glass microsphere and preparation method thereof

A chalcogenide glass, high-performance technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of unstable optical properties, low preparation efficiency, and low transmission power of chalcogenide glass microspheres, and achieve anti- The effect of high laser damage threshold, simple preparation process and high laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the composition of chalcogenide glass microspheres is Ge 8 As 32 S 60 ;

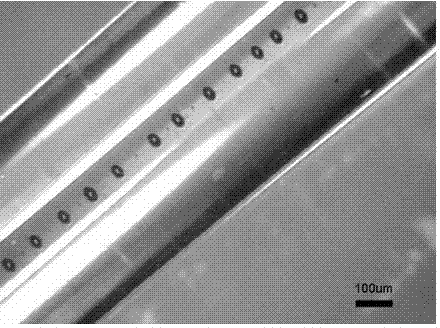

[0020] will be composed as Ge 8 As 32 S 60 1. Polish the surface of a chalcogenide glass rod with a diameter of 8mm, and then use a polyethersulfone resin PES film with a thickness of 125μm to wrap the glass rod tightly to a diameter of 25mm, put it in a vacuum furnace, evacuate to below 1Pa, and heat up to 240 o C, and keep it warm for 30 minutes to make the PES cladding dense, and then cool to room temperature; draw the obtained composite optical fiber preform with PES cladding on an optical fiber drawing tower into a thin rod with a diameter of 3 mm (the glass core diameter is about 1 mm); Cut out a thin rod with a length of 150mm, and use a PES film with a thickness of 75μm to rewind the thin rod to a diameter of 25mm, put it in a vacuum furnace, evacuate to below 1Pa, and slowly heat up to 240 o C, and keep it warm for 30 minutes to make the PES cladding dense, and then co...

Embodiment 2

[0023] Embodiment 2: the composition of chalcogenide glass microspheres is Ge 10 As 24 S 66 ;

[0024] will be composed as Ge 10 As 24 S 66 1. Polish the surface of a chalcogenide glass rod with a diameter of 6mm, then use polyetherimide PEI with a thickness of 75μm to roll the glass rod tightly to a diameter of 25mm, put it in a vacuum furnace, evacuate to below 1Pa, and heat up to 245 o C, and keep it warm for 20 minutes to make the PEI cladding dense, and then cool to room temperature; draw the obtained composite optical fiber preform with PEI cladding on an optical fiber drawing tower into a thin rod with a diameter of 2 mm (the glass core diameter is about 500 μm); Cut thin rods with a length of 150mm, stack 7 thin rods to form a multi-core structure with a diameter of 6mm, roll up the multi-core structure with a PEI film with a thickness of 75μm to a diameter of 25mm, put it in a vacuum furnace, and evacuate to 1Pa Below, slowly heat up to 245 o C, and keep it war...

Embodiment 3

[0027] Embodiment 3: the composition of chalcogenide glass microspheres is Ge 12 As 20 S 68 ;

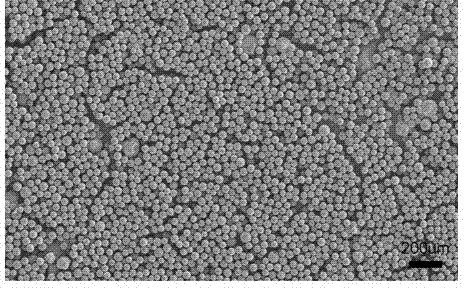

[0028] will be composed as Ge 12 As 20 S 68 1. Polish the surface of a chalcogenide glass rod with a diameter of 8mm, then use polyethersulfone resin PES with a thickness of 125μm to wrap the glass rod tightly to a diameter of 25mm, put it in a vacuum furnace, evacuate to below 1Pa, and heat up to 250 o C, and keep it warm for 10 minutes to make the PES cladding dense, and then cool to room temperature; draw the obtained optical fiber preform with PES cladding on a fiber drawing tower into an optical fiber with a diameter of 900 μm (the core diameter of the optical fiber is about 300 μm); Put the composite optical fiber with PES cladding into the quartz tube furnace and heat it to 350 o C, keep warm for 10 minutes, the glass in the fiber polymer cladding will break and form a large number of microspheres with uniform size; put the heat-treated fiber into 100ml N,N-dimethylacet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com