Method for preparing nitrogen carbon material by using animal waste, and application of nitrogen carbon material as oxygen reduction catalyst

A technology of nitrogen-carbon materials and animal manure, which is applied in the preparation of nitrogen-carbon materials and the field of nitrogen-carbon materials prepared from animal manure, which can solve the problems of lack of resources, high price, and restrictions on the wide application of fuel cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

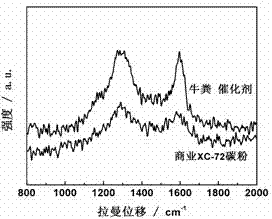

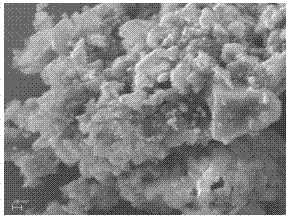

[0023] The collected cow dung was naturally air-dried at room temperature, calcined at 700°C for 2 h in a tube furnace under nitrogen protection, and put into a ball mill for 6 h until crushed. Weigh 1 g of sample, add 20 mL of nitric acid solution (2mol / L), stir magnetically for 24 h, wash with deionized water to make it neutral, and dry it in a blower box at 60 °C; then add 5 mL of FeCl 3 / C 2 h 5 OH solution (3mol / L), stirred for 0.5-1 h, dried in a blower box at 60 °C and then ball milled; finally, in a tube furnace, under nitrogen protection, high temperature treatment at 700 °C for 2 h to obtain nitrogen-carbon materials.

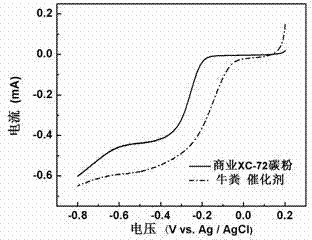

[0024] Through the oxygen reduction test, it was found that the nitrogen-carbon material was used as an oxygen reduction catalyst for the electrode of the combustion battery, and the onset potential and half-wave potential of the commercial XC-72 carbon powder oxygen reduction reaction were positively shifted by 30 mV and 34 mV, respectively.

Embodiment 2

[0026] The collected cow dung was naturally air-dried at room temperature, placed in a tube furnace under nitrogen protection, calcined at 800 °C for 2 h, and put into a ball mill for 6 h until crushed. Weigh 1 g of sample, add 50 mL of nitric acid solution (2 mol / L), stir magnetically for 24 h, wash with deionized water to make it neutral, and dry it in a blower box at 60 °C; then add 10 mL of FeCl 3 / C 2 h 5 OH solution (2mol / L), stirred for 0.5-1 h, dried in a blower box at 60 °C and continued to ball mill; finally, in a tube furnace, under nitrogen protection, high temperature treatment at 800 °C for 2 h to obtain nitrogen-carbon materials.

[0027] Through the oxygen reduction test, it was found that the nitrogen-carbon material was used as an oxygen reduction catalyst for the electrode of the combustion battery, and the onset potential and half-wave potential of the commercial XC-72 carbon powder oxygen reduction reaction were positively shifted by 96 mV and 88 mV, resp...

Embodiment 3

[0029] The collected cow dung was naturally air-dried at room temperature, placed in a tube furnace under nitrogen protection, calcined at 900 °C for 2 h, and put into a ball mill for 6 h to pulverize. Weigh 1 g of sample, add 100 mL of nitric acid solution (1mol / L), stir magnetically for 24 h, wash with deionized water to make it neutral, and dry it in a blower box at 60 °C; then add 40 mL of FeCl 3 / C 2 h 5 OH solution (0.5 mol / L), stirred for 0.5-1 h, dried in a blower box at 60 °C and continued to ball mill; finally, in a tube furnace, under nitrogen protection, high temperature treatment at 900 °C for 2 h to obtain nitrogen-carbon materials.

[0030] Through the oxygen reduction test, it was found that the nitrogen-carbon material was used as an oxygen reduction catalyst for the electrode of the combustion battery, and the onset potential and half-wave potential of the commercial XC-72 carbon powder oxygen reduction reaction were positively shifted by 46 mV and 58 mV, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com