Method for controlling geometric dimension of rubber product of nuclear power plant through temperature gradient

A technology for rubber products and geometric dimensions is applied in the field of using temperature gradient to control the geometric dimensions of rubber products in nuclear power plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Put 100kg of No. 1 smoked sheet glue, 5kg of zinc oxide, 1kg of stearic acid, 1kg of antiaging agent RD, 1kg of antiaging agent MB, 2kg of nano cerium oxide, 2kg of microcrystalline wax B10, 5kg of boron carbide, and 20kg of anthracene oil charcoal Black, 5kg dibutyl sebacate, 0.5kg accelerator TMTD, 1kg accelerator DM and 1.5kg vulcanizing agent DCP (dicumyl peroxide) are placed in the rubber mixer and mixed evenly;

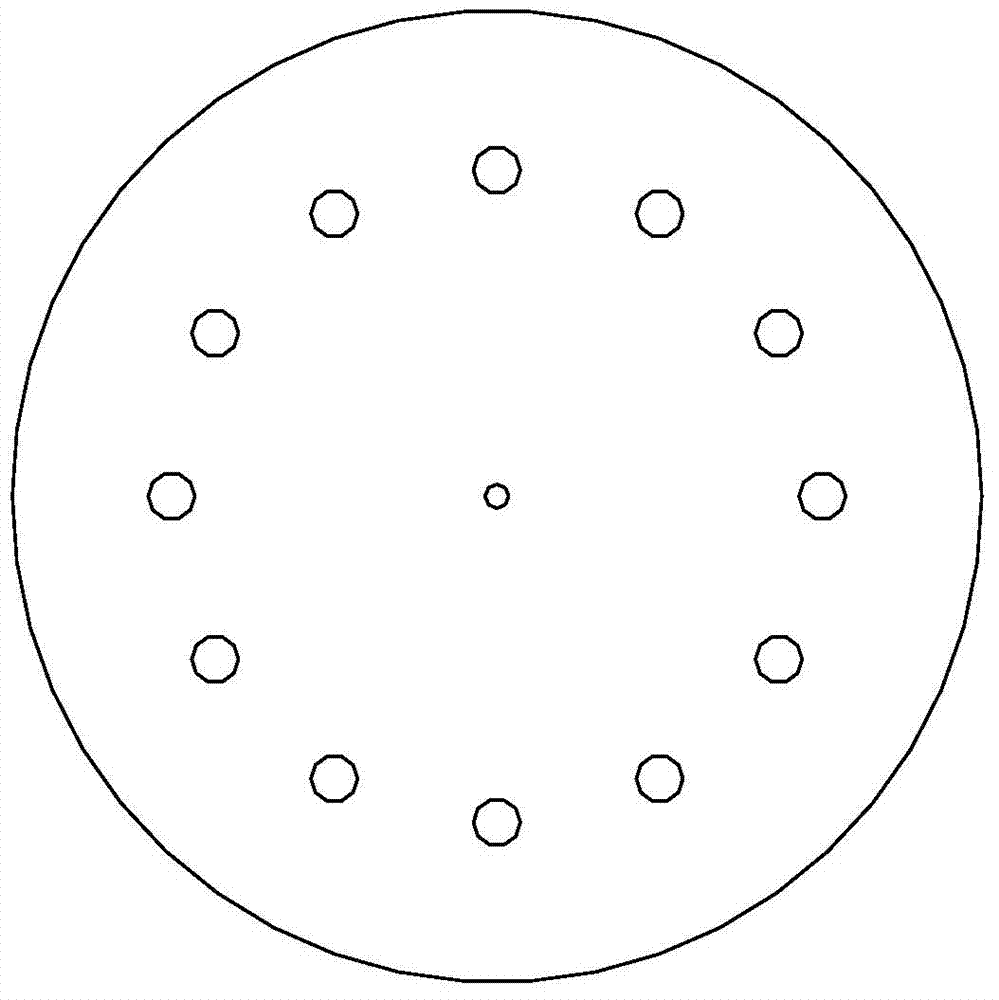

[0024] Step 2. Follow the shape of the rubber cup (see figure 1 ) and size (outer diameter 837mm) to select a mold, preheat the mold at 105°C, and then fill the preheated mold with the uniformly mixed raw materials in step 1;

[0025] Step 3, place the mold filled with raw materials in step 2 in a flat vulcanizer, and carry out vulcanization treatment under the condition of a pressure of 11MPa, and obtain a nuclear power plant nuclear reactor steam generator blocking plate rubber cup after demoulding; the vulcanization treatment The temperature c...

Embodiment 2

[0028] Step 1. Put 100kg No.1 smoked sheet glue, 3kg zinc oxide, 2kg stearic acid, 0.5kg antiaging agent RD, 0.5kg antiaging agent MB, 3kg nano cerium dioxide, 1kg microcrystalline wax B10, 6kg boron carbide, 18kg anthracene oil Carbon black, 4kg dibutyl sebacate, 0.5kg accelerator TMTD, 0.5kg accelerator DM and 1kg vulcanizing agent DCP (dicumyl peroxide) were placed in the rubber mixer and mixed evenly;

[0029] Step 2. Follow the shape of the rubber cup (see figure 1 ) and size (outer diameter 837mm) to select a mold, preheat the mold at 110°C, and then fill the preheated mold with the raw materials mixed uniformly in step 1;

[0030] Step 3, place the mold filled with raw materials in step 2 in a flat vulcanizer, and carry out vulcanization treatment under the condition of a pressure of 12MPa, and obtain the rubber cup of the nuclear reactor steam generator blocking plate of the nuclear power plant after demoulding; the vulcanization treatment The temperature control proc...

Embodiment 3

[0033]Step 1. Put 100kg No. 1 smoked sheet glue, 5kg zinc oxide, 2kg stearic acid, 2kg antiaging agent RD, 1kg antiaging agent MB, 1kg nano cerium oxide, 3kg microcrystalline wax B10, 4kg boron carbide, 22kg anthracene oil charcoal Black, 6kg dibutyl sebacate, 1kg accelerator TMTD, 1kg accelerator DM and 2kg vulcanizing agent DCP (dicumyl peroxide) are placed in the rubber mixer and mixed evenly;

[0034] Step 2. Follow the shape of the rubber cup (see figure 1 ) and size (outer diameter 837mm) to select a mold, preheat the mold at 100°C, and then fill the preheated mold with the raw materials mixed uniformly in step 1;

[0035] Step 3, place the mold filled with raw materials in step 2 in a flat vulcanizer, and carry out vulcanization treatment under the condition of a pressure of 10MPa, and obtain the rubber cup of the nuclear power plant nuclear reactor steam generator blocking plate rubber cup after demoulding; the vulcanization treatment The temperature control process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com