Preparation method of core-shell structure superfine fiber carrier material for medical dressing

A technology of ultra-fine fibers and carrier materials, applied in fiber processing, medical science, non-woven fabrics, etc., can solve the problems of poor fiber formation and difficult spinning of high polymers, and achieve controllable parameters, good biocompatibility, Good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 1g polyvinyl alcohol (the degree of polymerization is 1700, the degree of alcoholysis is 88%) with electronic balance scale and dissolve in 9g ultrapure water, prepare the solution that the mass fraction is 10%, in the water bath of 80 ℃, in the magnetic stirring Stir under the action of a device until completely dissolved to obtain a shell solution;

[0031] (2) take 0.4g chitosan (relative molecular weight 800,000, degree of deacetylation is 95%), 0.04g ciprofloxacin hydrochloride respectively with electronic balance, and dissolve it in 9.6g2% In the acetic acid solution, under the action of magnetic stirrer, stir until completely dissolving to obtain nuclear layer solution;

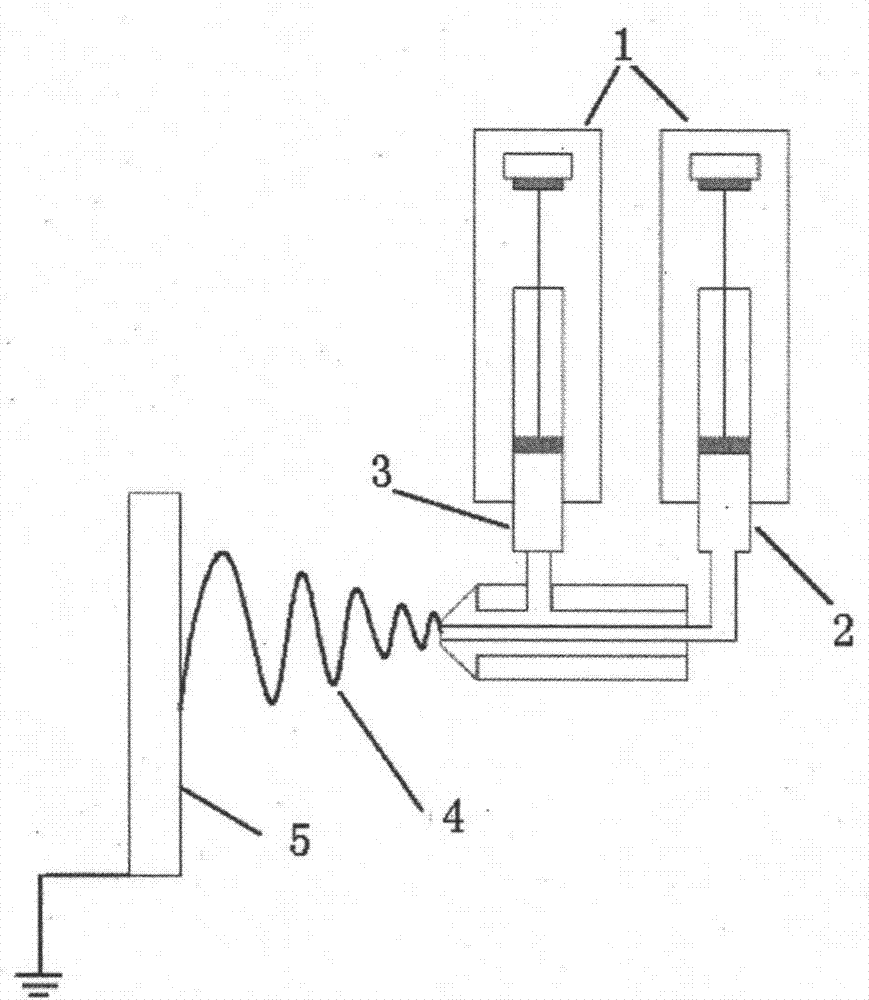

[0032] (3) using such as figure 1 The electrospinning device shown is for coaxial electrospinning, the feed rate of the core solution is set to 0.06mL / h, the diameter of the inner spinneret is 0.5mm, and the feed rate of the shell solution is 0.6mL / h. The diameter of the outer spinner...

Embodiment 2

[0035](1) Take 1g polyvinyl alcohol (the degree of polymerization is 1700, the degree of alcoholysis is 88%) with the electronic balance scale and dissolve in 9g ultrapure water, prepare the solution that the mass fraction is 10%, in the water bath of about 80 ℃ Stir under the action of a magnetic stirrer until completely dissolved to obtain a shell solution;

[0036] (2) Dissolve 0.1g of sodium alginate in 9.9g of ultrapure water with an electronic balance to obtain a sodium alginate solution with a mass fraction of 1%, and stir it under the action of a magnetic stirrer at room temperature until it is completely dissolved to obtain a nuclear layer solution ;

[0037] (3) using such as figure 1 The electrospinning device shown is for coaxial electrospinning, the feed rate of the core layer solution is set to 0.07mL / h, the diameter of the inner spinneret is 0.5mm, and the feed rate of the shell layer solution is 0.7mL / h. The diameter of the outer spinneret is 1.26mm; the appl...

Embodiment 3

[0040] (1) get 0.36g chitosan (relative molecular weight 800,000, degree of deacetylation is 95%), 0.04g ethylene oxide (relative molecular weight is 900KDa) and dissolve in the acetic acid solution of 9.6g90% with electronic balance scale, obtain mass The solution with a fraction of 4%, was stirred under the action of a magnetic stirrer at room temperature until it was completely dissolved to obtain a shell solution:

[0041] (2) Dissolve 0.1 g of sodium alginate in 9.9 g of ultrapure water with an electronic balance, and stir under the action of a magnetic stirrer at room temperature until completely dissolved to obtain a nuclear layer solution;

[0042] (3) using such as figure 1 The electrospinning device shown is for coaxial electrospinning, the feed rate of the core layer solution is set to 0.07mL / h, the diameter of the inner spinneret is 0.5mm, and the feed rate of the shell layer solution is 0.7mL / h. The diameter of the outer spinneret is 1.26mm; the applied voltage i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Dimension diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com