Preparation method of low-permeability oral rehydration salt

A technology for rehydration salts and prescriptions, which is applied in the field of preparation of hypotonic oral rehydration salts, which can solve problems such as affecting drug packaging, difficulty in mixing uniformly, and unqualified content uniformity, and achieve a fast and smooth mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

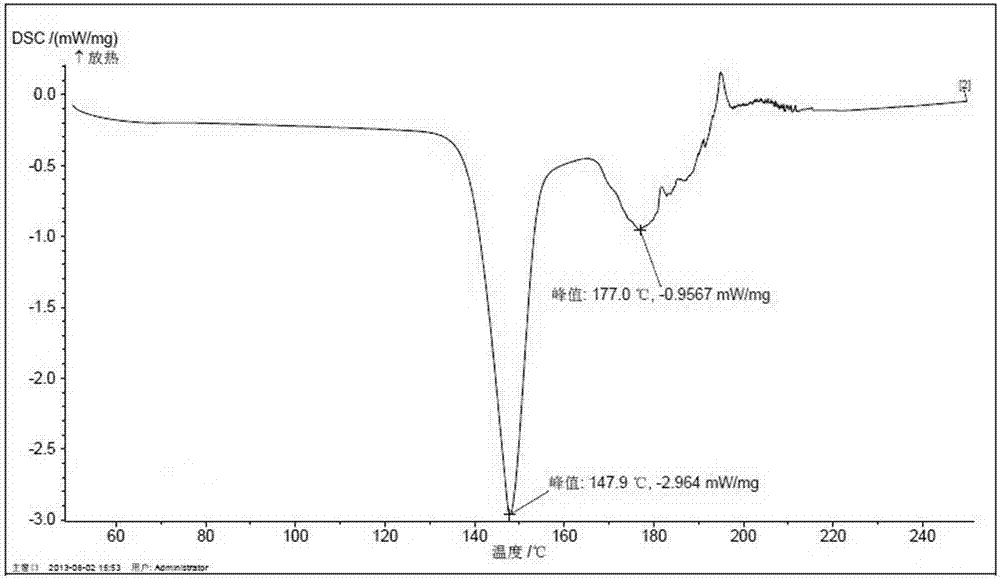

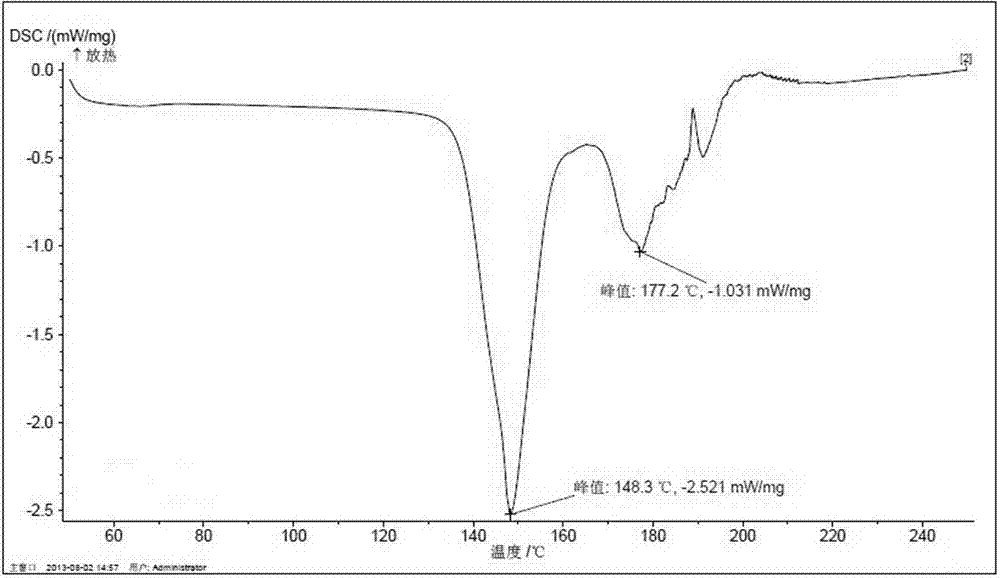

Image

Examples

Embodiment 1

[0026] Prescription: 0.65Kg sodium chloride, 0.375Kg potassium chloride, 0.725Kg sodium citrate, 3.375Kg anhydrous glucose.

[0027] Preparation:

[0028] (1) Pulverize anhydrous glucose with 20% prescription amount together with sodium chloride, potassium chloride and sodium citrate, and pass through a 100-mesh sieve;

[0029] (2) Crush the remaining anhydrous glucose and pass through a 100-mesh sieve;

[0030] (3) Mix the mixture in step (1) with the anhydrous glucose in step (2) evenly, and take samples to test the content uniformity of intermediates;

[0031] (4) Divide according to the marked amount of 5.125g / bag to obtain the product.

[0032] Process control of mixing uniformity in step (3):

[0033] Potassium chloride has the lowest proportion in the total blend material, which is 7.32%. Therefore, it is judged whether the material is evenly mixed by testing the content uniformity of potassium chloride. The method for checking the uniformity of potassium chloride c...

Embodiment 2

[0036] Prescription: 0.65Kg sodium chloride, 0.375Kg potassium chloride, 0.725Kg sodium citrate, 3.375Kg anhydrous glucose.

[0037] Preparation:

[0038] (1) Pulverize anhydrous glucose with 10% prescription amount and sodium chloride, and pass through a 100-mesh sieve;

[0039] (2) Grind 20% of the prescription amount of anhydrous glucose with potassium chloride and sodium citrate, and pass through a 100-mesh sieve

[0040] (3) Crush the remaining anhydrous glucose and pass through a 100-mesh sieve;

[0041] (4) Mix the mixture in steps (1), (2) and the anhydrous glucose in step (3) together evenly, and take samples to test the content uniformity of intermediates;

[0042] (5) Divide according to the marked amount of 5.125g / bag, and get ready.

Embodiment 3

[0044] Prescription: 0.65Kg sodium chloride, 0.375Kg potassium chloride, 0.725Kg sodium citrate, 3.375Kg anhydrous glucose.

[0045] Preparation:

[0046] (1) Grinding 20% of the prescription amount of anhydrous glucose with sodium chloride and potassium chloride, and passing through a 100-mesh sieve;

[0047] (2) Grind anhydrous glucose with 10% prescription amount and sodium citrate, and pass through a 100-mesh sieve

[0048] (3) Crush the remaining anhydrous glucose and pass through a 100-mesh sieve;

[0049] (4) Mix the mixture in steps (1), (2) and the anhydrous glucose in step (3) together evenly, and take samples to test the content uniformity of intermediates;

[0050] (5) Divide according to the marked amount of 5.125g / bag, and get ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com