Isosorbide mononitrate sustained-release pallets, preparation prepared from same and preparation method for isosorbide mononitrate sustained-release pallets

A technology of isosorbide mononitrate and sustained-release pellets, which is applied in the field of medicine, can solve the problems of poor stability of isosorbide mononitrate sustained-release capsules, and achieve the effects of avoiding significant changes, simple operation, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

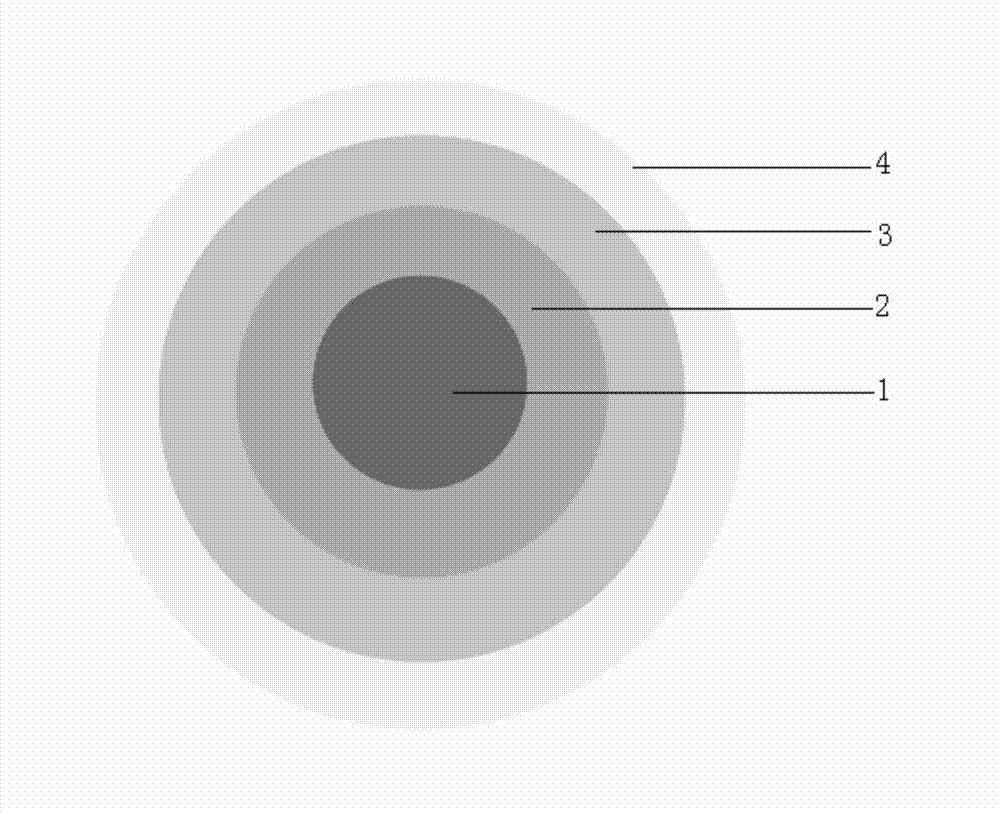

[0110] The preparation of embodiment 1 isosorbide mononitrate slow-release pellets

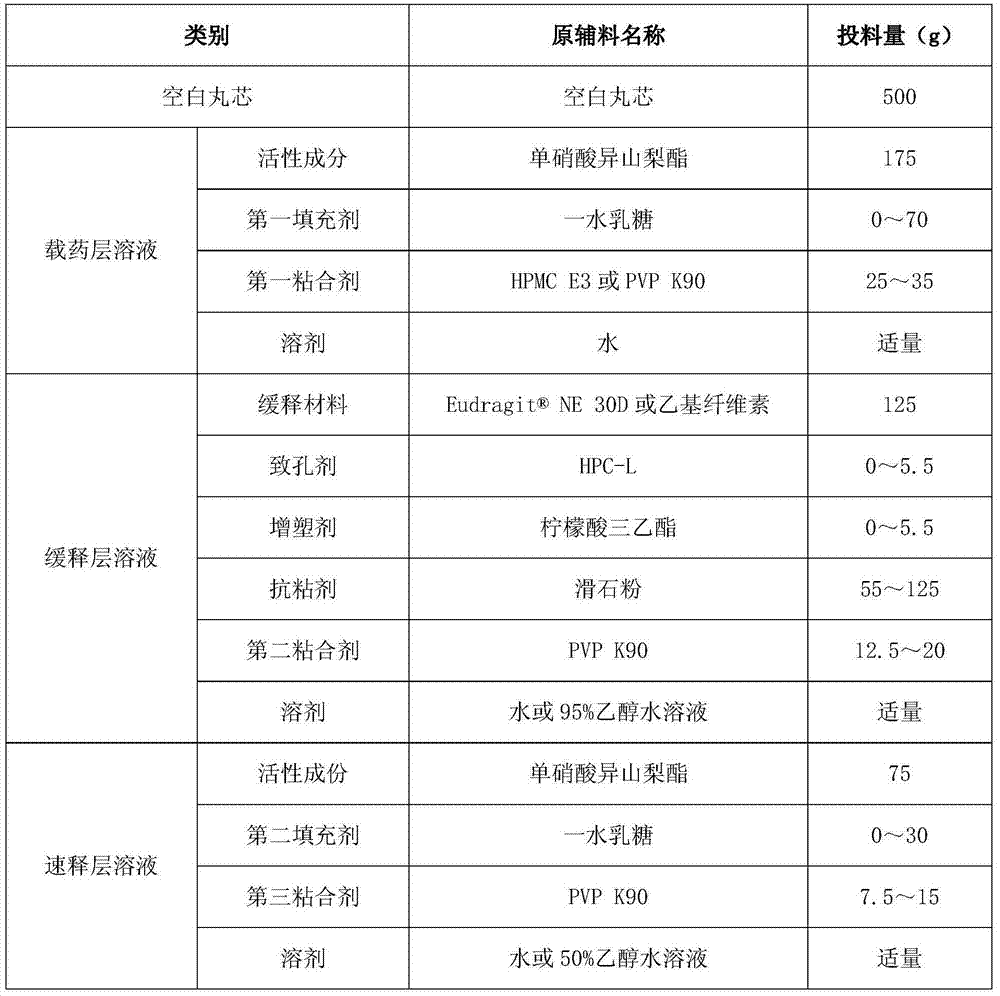

[0111] Add 25g of HPMC E3 into 500g of purified water at 50°C, stir and swell until clear, and cool to the greenhouse for use; add 175g of isosorbide mononitrate, stir evenly, and obtain a suspension. Pass the above suspension through an 80-mesh sieve, rinse it with 250 g of purified water, add 500 g of purified water, and stir evenly to obtain a drug-loaded layer solution. Fill 500g of sucrose-starch microspheres (particle size 0.6~0.8mm) into the fluidized bed granulation coating machine, fan frequency 20~40Hz, air inlet temperature 50~70℃, material temperature 40~50℃, atomization The air pressure is 0.05-0.10MPa, and the spraying pump speed is 10-30 rpm to carry out the drug feeding operation (coating) until the solution of the drug-loaded layer is sprayed out. Set the material temperature at 40°C, fluidize and dry the pellets coated with the drug-loaded layer solution for 2 hours until th...

Embodiment 2

[0118] The preparation of embodiment 2 isosorbide mononitrate slow-release pellets

[0119] Add 25g of HPMC E3 to 500g of purified water at 50°C, stir and swell to clarification, and cool to the greenhouse for use; take 43.8g of lactose monohydrate, add to the above solution and stir to dissolve; add 175g of isosorbide mononitrate, stir evenly, and obtain suspension. Pass the above suspension through an 80-mesh sieve, rinse it with 250 g of purified water, add 500 g of purified water, and stir evenly to obtain a drug-loaded layer solution. Fill 500g of sucrose-starch microspheres (particle size 0.6~0.8mm) into the fluidized bed granulation coating machine, fan frequency 20~40Hz, air inlet temperature 50~70℃, material temperature 40~50℃, atomization The air pressure is 0.05-0.10MPa, and the spraying pump speed is 10-30 rpm to carry out the drug feeding operation (coating) until the solution of the drug-loaded layer is sprayed out. Set the material temperature at 40°C, fluidiz...

Embodiment 3

[0126] The preparation of embodiment 3 isosorbide mononitrate slow-release pellets

[0127] Add 25g of PVP K90 to 500g of purified water at 25°C, stir and dissolve until clear and ready for use; take 43.8g of lactose monohydrate, add to the above solution and stir to dissolve; add 175g of isosorbide mononitrate, stir well to obtain a suspension. Pass the above suspension through an 80-mesh sieve, rinse it with 250 g of purified water, add 500 g of purified water, and stir evenly to obtain a drug-loaded layer solution. Fill 500g of sucrose-starch microspheres (particle size 0.6~0.8mm) into the fluidized bed granulation coating machine, fan frequency 20~40Hz, air inlet temperature 50~70℃, material temperature 40~50℃, atomization The air pressure is 0.05-0.10MPa, and the spraying pump speed is 10-30 rpm to carry out the drug feeding operation (coating) until the solution of the drug-loaded layer is sprayed out. Set the material temperature at 40°C, fluidize and dry the pellets c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com