Method for forming electrodes of IBC solar cell

A solar cell and electrode technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the photoelectric conversion efficiency of the battery, the large amount of silver solution used, and the high cost of the battery, so as to ensure the photoelectric conversion efficiency and reduce the silver content. , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

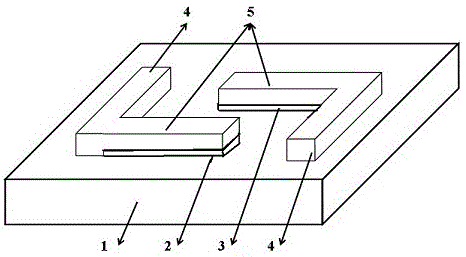

[0013] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention prints electrodes by using different electrode pastes in batches, firstly printing the fine grids of the positive and negative electrodes for the first time, and then printing the main grids for the second time or printing the main grid lines and the fine grid lines at the same time, These three printing pastes all use different electrode pastes. The order of the fine grid electrodes of the positive and negative electrodes printed for the first time is the positive electrode first and then the negative electrode, or the negative electrode first and then the positive electrode. The silver content of the paste for printing the fine grid for the first time is about 80%-95%. The silver content of the silver paste for the second printing of the busbar is lower than that of the first printing silver paste, and copper, nickel, aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com