A method for adding sawdust to remove silver from silver-containing tin alloy

A technology of silver-tin alloy and wood chips, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of inability to handle high lead solder, high capital construction investment cost, hydrometallurgical pollution, etc., to promote secondary nucleation and growth. , The effect of high universality of raw materials and a wide range of silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

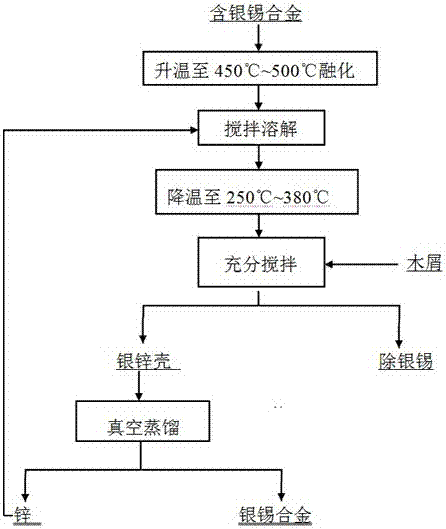

[0018] Such as figure 1 Shown, this adds sawdust to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0019] Step 1. First, heat up 10 tons of silver-containing tin alloy (the silver content in the silver-containing tin alloy is 1.5g / t, and the rest is tin) to 450°C and fully melt it. 1:4 add crude zinc, fully stir to dissolve;

[0020] Step 2. Cool the silver-containing tin alloy treated in step 1 to 250°C, add sawdust whose mass is 5 times the silver in the crude zinc, stir well, remove the slag, repeat the operation, and observe that the floating matter is black carbon particles, stop removing the slag operation, and finally obtain liquid tin with low silver content and silver-zinc shell containing carbon particles, and the liquid tin can be desilvered tin after cooling.

[0021] Wherein the silver-zinc shell in step 2 is subjected to vacuum distillation to obtain crude zinc and silver; the crude zinc obtained by vacuu...

Embodiment 2

[0024] Such as figure 1 Shown, this adds sawdust to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0025] Step 1. First, heat up 10 tons of silver-containing tin alloy (the silver content in the silver-containing tin alloy is 5000g / t, and the rest is tin) to 500°C and fully melt it, and the molar ratio of silver in the silver-containing tin alloy to zinc in the crude zinc is 1 : 6 Add crude zinc, fully stir and dissolve;

[0026] Step 2. Cool the silver-containing tin alloy treated in step 1 to 300°C, add sawdust whose mass is 5 times the silver in the crude zinc, stir well, remove the slag, repeat the operation, and observe that the floating matter is black carbon particles, stop removing the slag operation, and finally obtain liquid tin with low silver content and silver-zinc shell containing carbon particles, and the liquid tin can be desilvered tin after cooling.

[0027] Wherein the silver-zinc shell in step 2 is ...

Embodiment 3

[0030] Such as figure 1 Shown, this adds sawdust to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0031] Step 1. First, heat up 10 tons of silver-containing tin alloy (the silver content in the silver-containing tin alloy is 25000g / t, and the rest is tin) to 550°C and fully melt it, and mix it according to the molar ratio of silver in the silver-containing tin alloy to zinc in the crude zinc: 1 : 9 add thick zinc, fully stir and dissolve;

[0032] Step 2. Cool the silver-containing tin alloy treated in step 1 to 380°C, add wood chips whose mass is 5 times the silver in the crude zinc, stir well, remove the slag, repeat the operation, and observe that the floating matter is black carbon particles, stop removing the slag operation, and finally obtain liquid tin with low silver content and silver-zinc shell containing carbon particles, and the liquid tin can be desilvered tin after cooling.

[0033] Wherein the silver-zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com