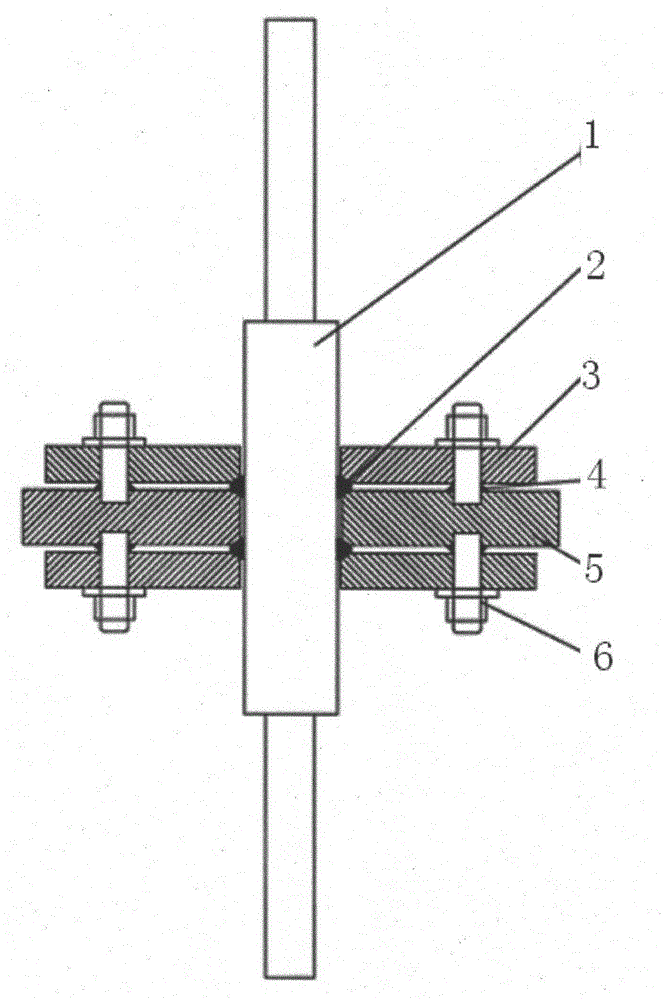

Low-voltage high-current conducting bar fixing mode of electric furnace transformer

A technology of transformers and conductive bars, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve the problems that affect the compression of the gasket 2, the heat of the screw 6 is severe, and the holes on both sides of the non-magnetic steel plate 5 cannot be opened through, etc. Achieve the effect of preventing excessive heating and reducing the probability of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

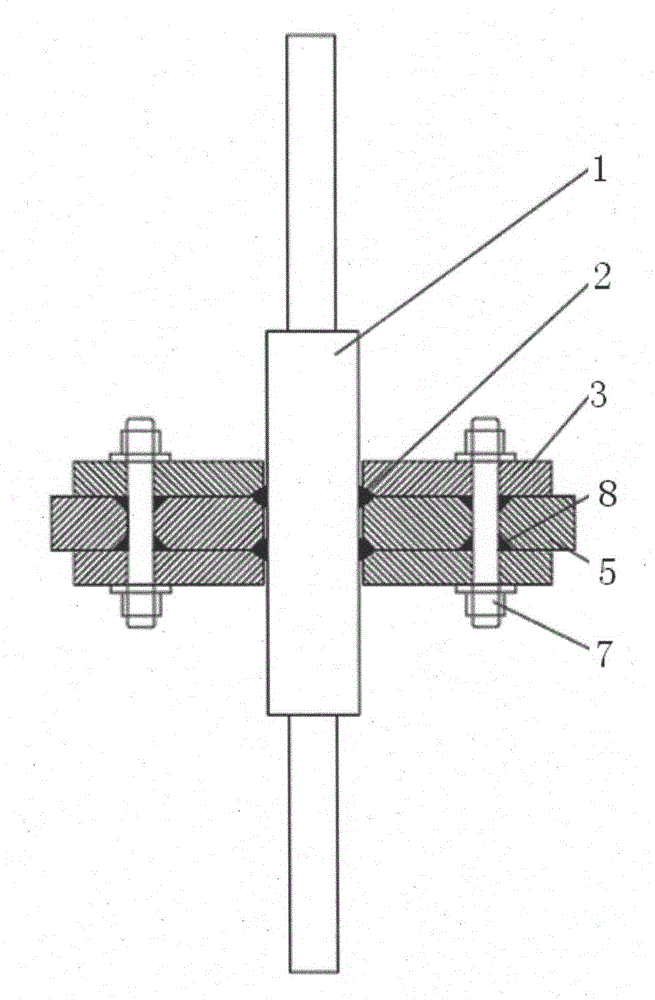

[0015] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0016] combine figure 2 , the invention provides a method for fixing the low-voltage and high-current conductive bars of electric furnace transformers, the steps of which are as follows:

[0017] Step 1. Fix the conductive bar 1 on the non-magnetic steel plate 5;

[0018] Step 2, opening through holes at the left and right ends of the non-magnetic steel plate 5, respectively chamfering grooves at the upper and lower ends of each through hole;

[0019] Step 3. Insert a non-magnetic screw rod 7 into each of the two through holes. The upper and lower ends of the non-magnetic screw rod 7 are respectively exposed to the upper and lower sides of the non-magnetic steel plate 5, and the beveled groove is used as the weld seam 8. Fix the non-magnetic screw rod 7 and the non-magnetic steel plate 5 by welding, and ensure that the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com