Motorcycle frame front body assembly convenient for welding oil pool

A motorcycle and frame technology, applied in the field of motorcycle frame structure, can solve the problems of high oil leakage rate of oil cooling system, difficult welding of oil pool, low service life of the frame, etc., so as to reduce the probability of oil leakage and the difficulty of welding The effect of reduction and reasonable distribution of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

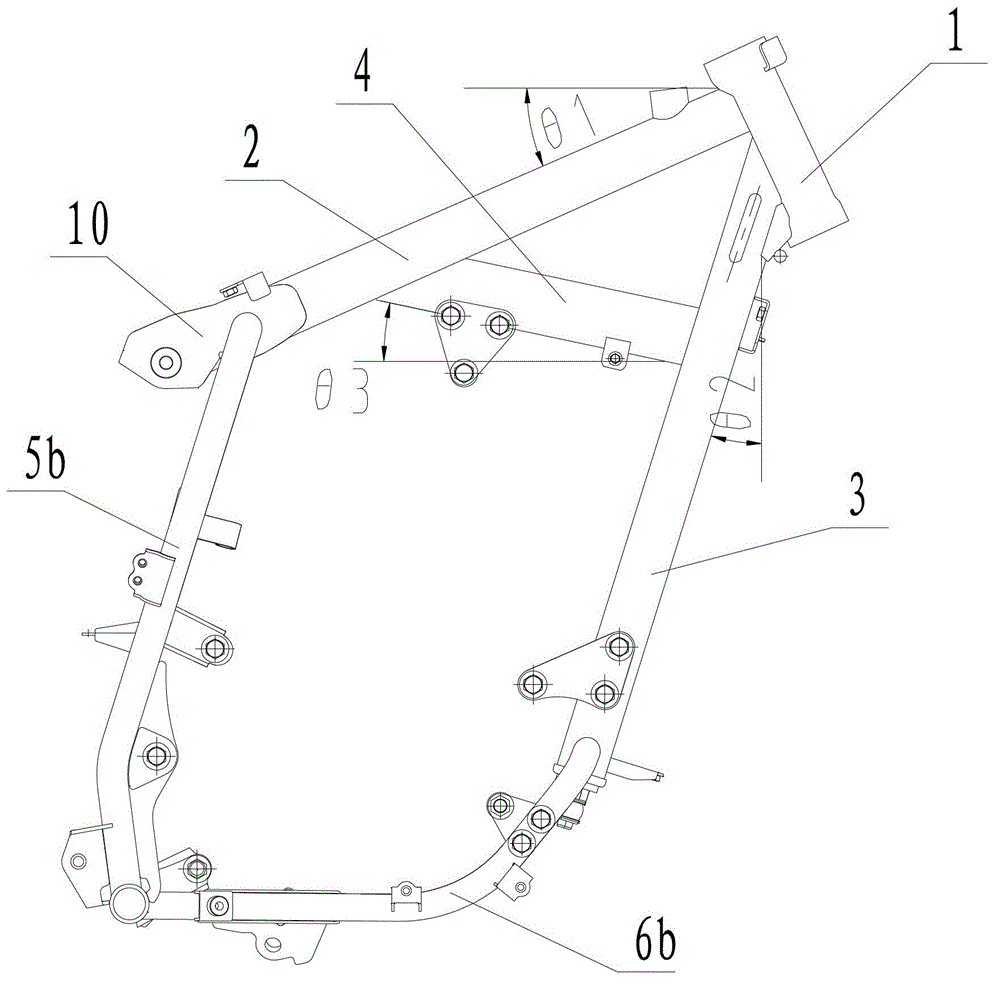

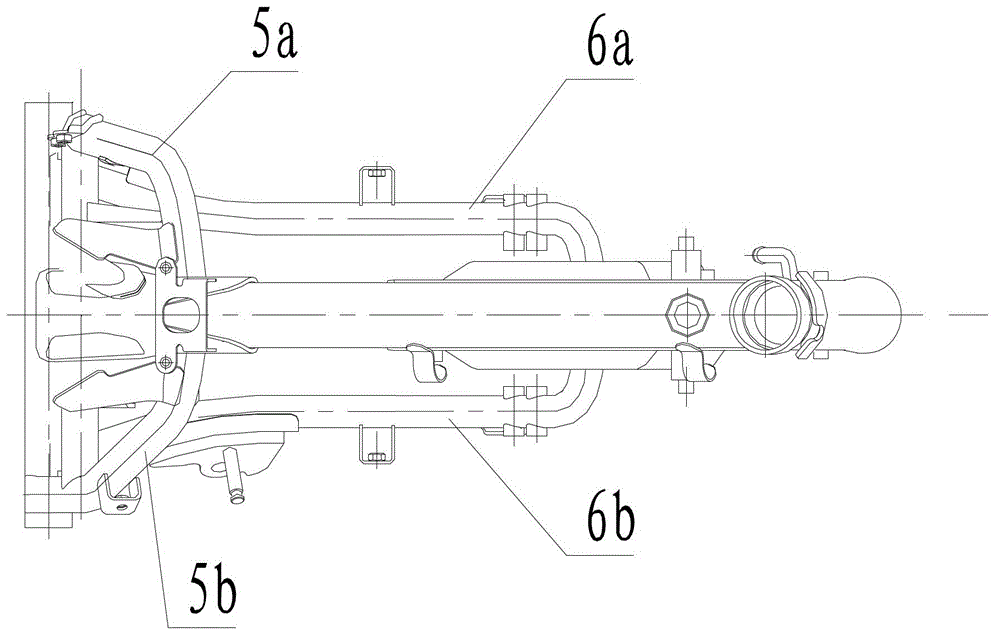

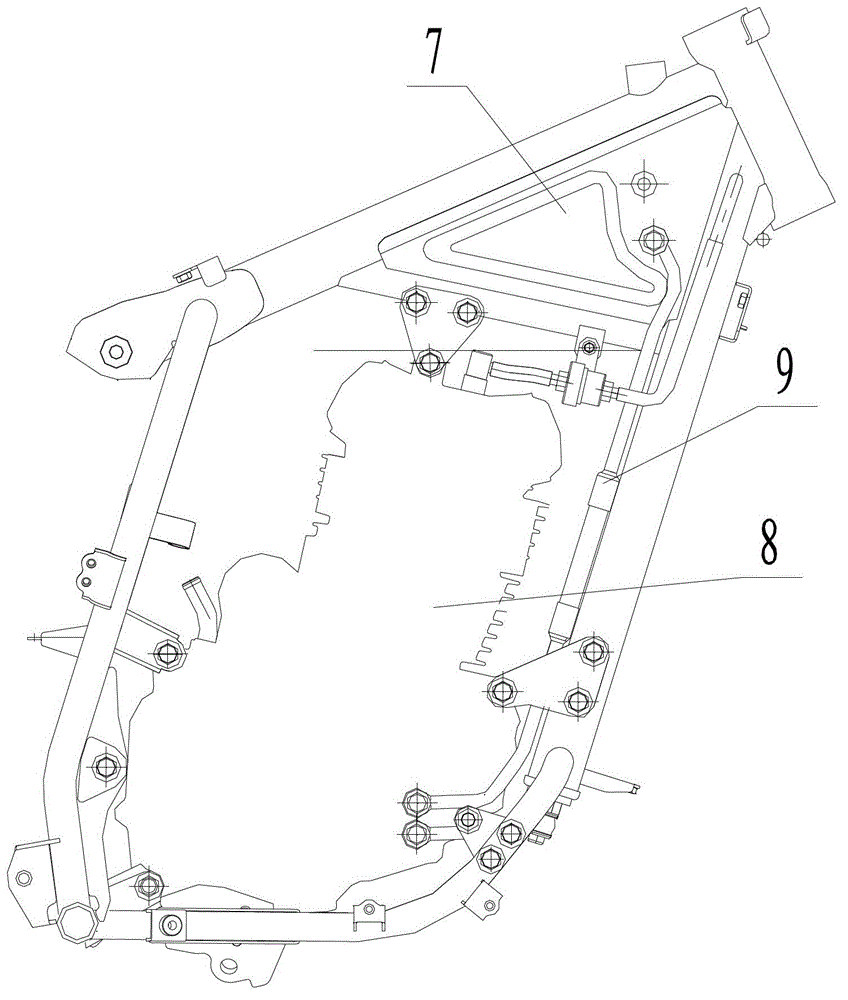

[0012] Such as figure 1 and figure 2 As shown, a front body assembly of a motorcycle frame that is convenient for welding the oil pool includes a head pipe 1, a front main pipe 2 and a front inclined pipe 3 are welded on the same side of the head pipe 1, and the front main pipe 2 and the front inclined pipe 3 are welded on the same side. Front support pipe 4 is welded between. The head pipe 1, the front main pipe 2, the front inclined pipe 3 and the front support pipe 4 are all straight pipes.

[0013] The lower part of the front main pipe 2 is provided with an upper mounting bracket assembly 10 on the rear shock absorber, the upper mounting bracket assembly 10 on the rear shock absorber is welded with a left main pipe 5a and a right main pipe 5b, and the lower part of the front inclined pipe 3 is welded with a left lower main pipe 6a and a right Lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com